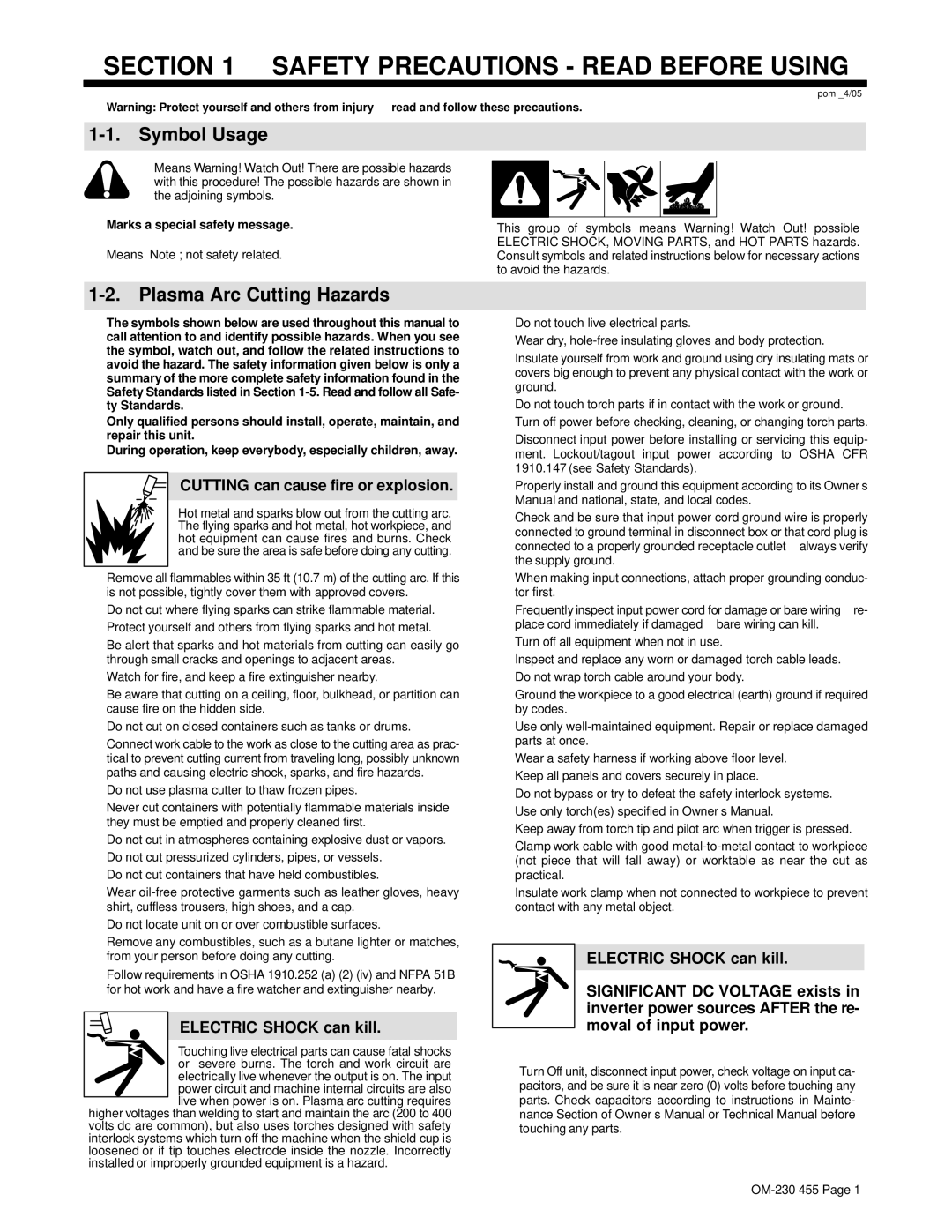

Means Warning! Watch Out! There are possible hazards with this procedure! The possible hazards are shown in the adjoining symbols.

YMarks a special safety message.

.Means “Note”; not safety related.

1-2. Plasma Arc Cutting Hazards

YThe symbols shown below are used throughout this manual to call attention to and identify possible hazards. When you see the symbol, watch out, and follow the related instructions to avoid the hazard. The safety information given below is only a summary of the more complete safety information found in the Safety Standards listed in Section 1-5.Read and follow all Safe- ty Standards.

YOnly qualified persons should install, operate, maintain, and repair this unit.

YDuring operation, keep everybody, especially children, away.

CUTTING can cause fire or explosion.

Hot metal and sparks blow out from the cutting arc. The flying sparks and hot metal, hot workpiece, and hot equipment can cause fires and burns. Check and be sure the area is safe before doing any cutting.

DRemove all flammables within 35 ft (10.7 m) of the cutting arc. If this is not possible, tightly cover them with approved covers.

DDo not cut where flying sparks can strike flammable material.

DProtect yourself and others from flying sparks and hot metal.

DBe alert that sparks and hot materials from cutting can easily go through small cracks and openings to adjacent areas.

DWatch for fire, and keep a fire extinguisher nearby.

DBe aware that cutting on a ceiling, floor, bulkhead, or partition can cause fire on the hidden side.

DDo not cut on closed containers such as tanks or drums.

DConnect work cable to the work as close to the cutting area as prac- tical to prevent cutting current from traveling long, possibly unknown paths and causing electric shock, sparks, and fire hazards.

DDo not use plasma cutter to thaw frozen pipes.

DNever cut containers with potentially flammable materials inside − they must be emptied and properly cleaned first.

DDo not cut in atmospheres containing explosive dust or vapors.

DDo not cut pressurized cylinders, pipes, or vessels.

DDo not cut containers that have held combustibles.

DWear oil-free protective garments such as leather gloves, heavy shirt, cuffless trousers, high shoes, and a cap.

DDo not locate unit on or over combustible surfaces.

DRemove any combustibles, such as a butane lighter or matches, from your person before doing any cutting.

DFollow requirements in OSHA 1910.252 (a) (2) (iv) and NFPA 51B for hot work and have a fire watcher and extinguisher nearby.

ELECTRIC SHOCK can kill.

Touching live electrical parts can cause fatal shocks or severe burns. The torch and work circuit are electrically live whenever the output is on. The input power circuit and machine internal circuits are also live when power is on. Plasma arc cutting requires

higher voltages than welding to start and maintain the arc (200 to 400 volts dc are common), but also uses torches designed with safety interlock systems which turn off the machine when the shield cup is loosened or if tip touches electrode inside the nozzle. Incorrectly installed or improperly grounded equipment is a hazard.

This group of symbols means Warning! Watch Out! possible ELECTRIC SHOCK, MOVING PARTS, and HOT PARTS hazards. Consult symbols and related instructions below for necessary actions to avoid the hazards.

DDo not touch live electrical parts.

DWear dry, hole-free insulating gloves and body protection.

DInsulate yourself from work and ground using dry insulating mats or covers big enough to prevent any physical contact with the work or ground.

DDo not touch torch parts if in contact with the work or ground.

DTurn off power before checking, cleaning, or changing torch parts.

DDisconnect input power before installing or servicing this equip- ment. Lockout/tagout input power according to OSHA CFR 1910.147 (see Safety Standards).

DProperly install and ground this equipment according to its Owner’s Manual and national, state, and local codes.

DCheck and be sure that input power cord ground wire is properly connected to ground terminal in disconnect box or that cord plug is connected to a properly grounded receptacle outlet − always verify the supply ground.

DWhen making input connections, attach proper grounding conduc- tor first.

DFrequently inspect input power cord for damage or bare wiring − re- place cord immediately if damaged − bare wiring can kill.

DTurn off all equipment when not in use.

DInspect and replace any worn or damaged torch cable leads.

DDo not wrap torch cable around your body.

DGround the workpiece to a good electrical (earth) ground if required by codes.

DUse only well-maintained equipment. Repair or replace damaged parts at once.

DWear a safety harness if working above floor level.

DKeep all panels and covers securely in place.

DDo not bypass or try to defeat the safety interlock systems.

DUse only torch(es) specified in Owner’s Manual.

DKeep away from torch tip and pilot arc when trigger is pressed.

DClamp work cable with good metal-to-metal contact to workpiece (not piece that will fall away) or worktable as near the cut as practical.

DInsulate work clamp when not connected to workpiece to prevent contact with any metal object.

ELECTRIC SHOCK can kill.

SIGNIFICANT DC VOLTAGE exists in inverter power sources AFTER the re- moval of input power.

DTurn Off unit, disconnect input power, check voltage on input ca- pacitors, and be sure it is near zero (0) volts before touching any parts. Check capacitors according to instructions in Mainte- nance Section of Owner’s Manual or Technical Manual before touching any parts.

OM-230 455 Page 1