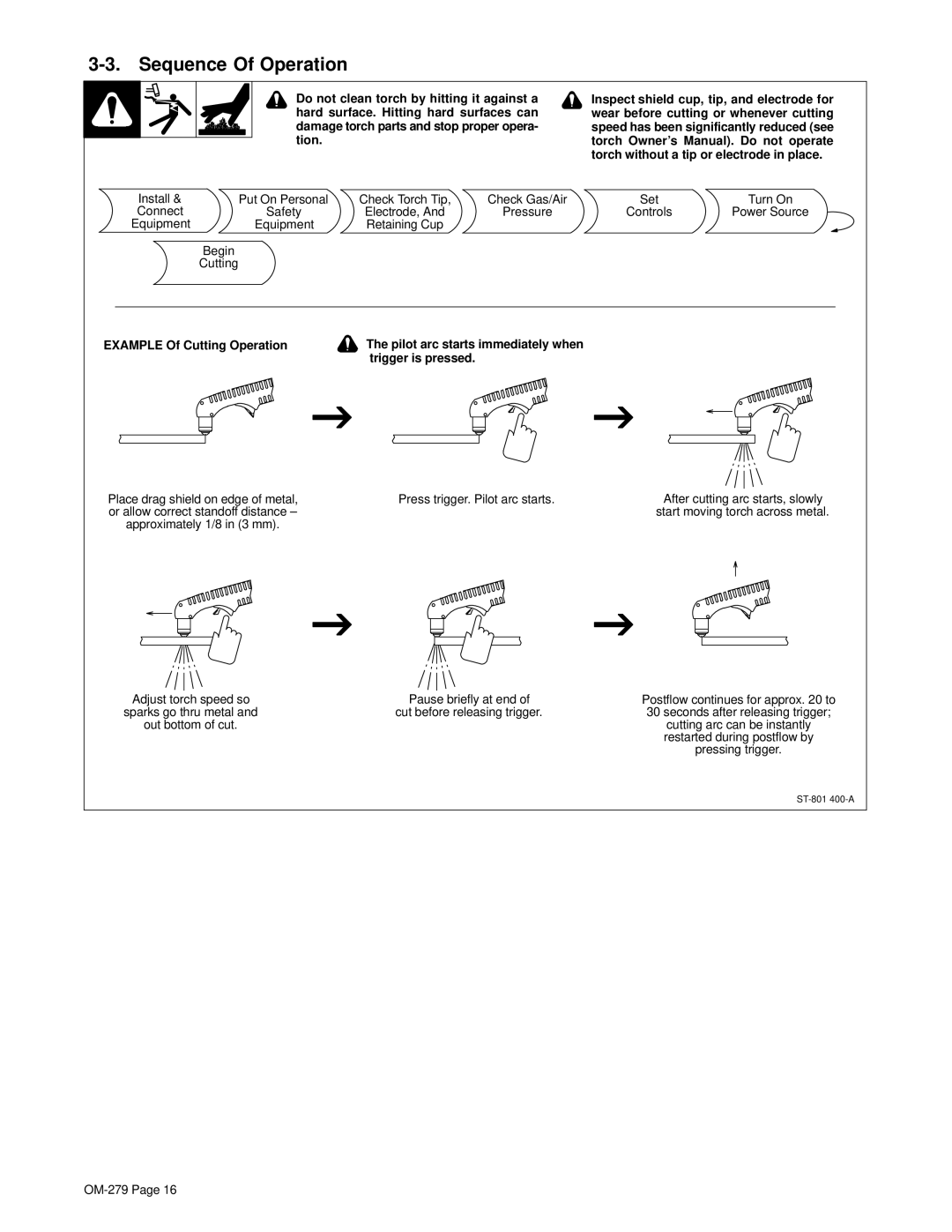

3-3. Sequence Of Operation

Do not clean torch by hitting it against a hard surface. Hitting hard surfaces can damage torch parts and stop proper opera- tion.

Inspect shield cup, tip, and electrode for wear before cutting or whenever cutting speed has been significantly reduced (see torch Owner’s Manual). Do not operate torch without a tip or electrode in place.

Install & | Put On Personal | Check Torch Tip, | Check Gas/Air | Set | Turn On |

Connect | Safety | Electrode, And | Pressure | Controls | Power Source |

Equipment | Equipment | Retaining Cup |

|

|

|

| Begin |

|

|

|

|

| Cutting |

|

|

|

|

EXAMPLE Of Cutting Operation | The pilot arc starts immediately when |

| trigger is pressed. |

Place drag shield on edge of metal, | Press trigger. Pilot arc starts. |

or allow correct standoff distance – |

|

approximately 1/8 in (3 mm). |

|

After cutting arc starts, slowly start moving torch across metal.

Adjust torch speed so | Pause briefly at end of | Postflow continues for approx. 20 to |

sparks go thru metal and | cut before releasing trigger. | 30 seconds after releasing trigger; |

out bottom of cut. |

| cutting arc can be instantly |

|

| restarted during postflow by |

|

| pressing trigger. |

|

|