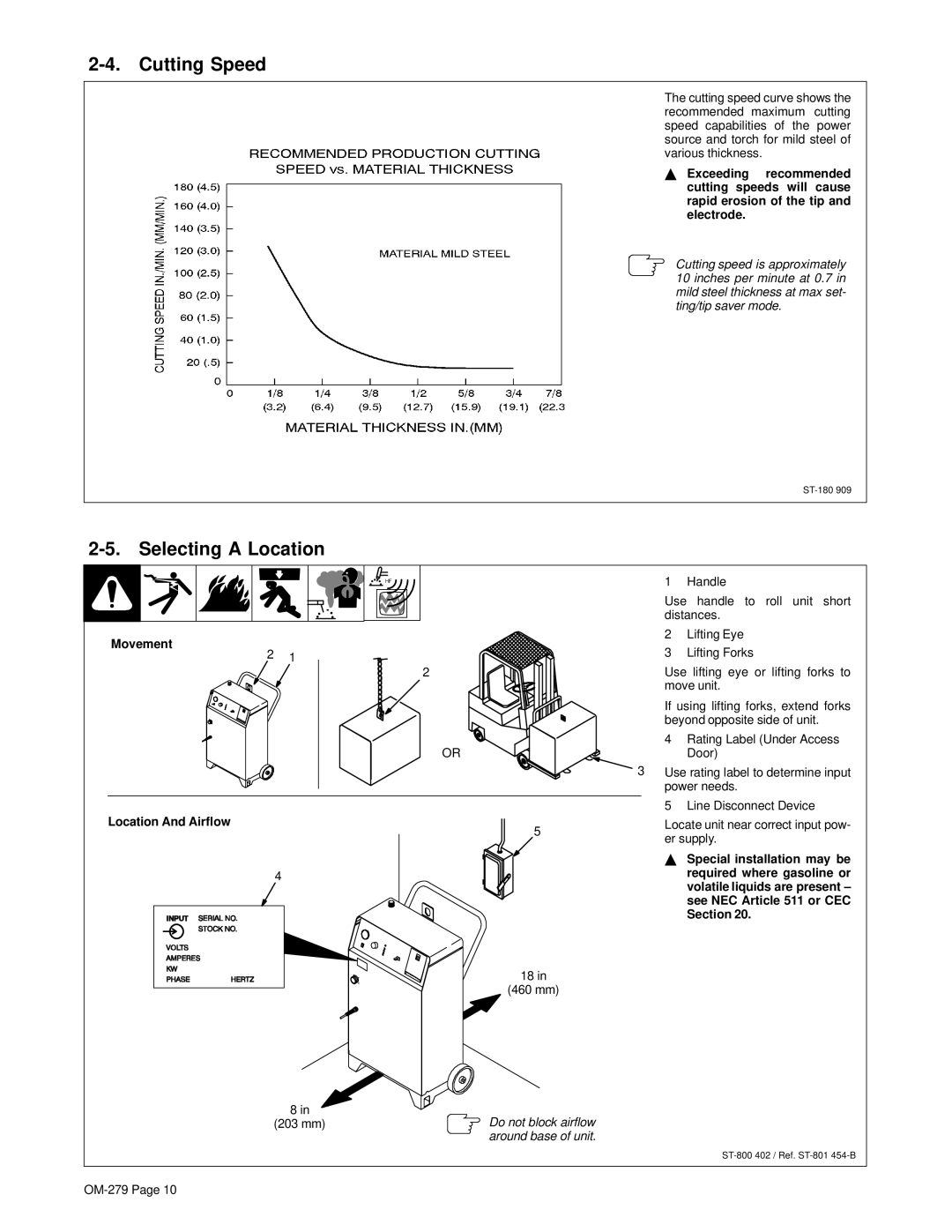

2-4. Cutting Speed

The cutting speed curve shows the recommended maximum cutting speed capabilities of the power source and torch for mild steel of various thickness.

Y Exceeding recommended cutting speeds will cause rapid erosion of the tip and electrode.

Cutting speed is approximately 10 inches per minute at 0.7 in mild steel thickness at max set- ting/tip saver mode.

2-5. Selecting A Location

Movement

2 1

Location And Airflow

4

|

| 1 | Handle |

|

| Use handle to roll unit short | |

|

| distances. | |

|

| 2 | Lifting Eye |

|

| 3 | Lifting Forks |

2 |

| Use | lifting eye or lifting forks to |

|

| move unit. | |

|

| If using lifting forks, extend forks | |

|

| beyond opposite side of unit. | |

|

| 4 | Rating Label (Under Access |

| OR |

| Door) |

|

| 3 Use rating label to determine input | |

|

| power needs. | |

|

| 5 | Line Disconnect Device |

| 5 | Locate unit near correct input pow- | |

| er supply. | ||

|

| ||

|

| Y Special installation may be | |

|

|

| required where gasoline or |

|

|

| volatile liquids are present – |

|

|

| see NEC Article 511 or CEC |

|

|

| Section 20. |

18in

(460 mm)

8 in

(203 mm)Do not block airflow around base of unit.