Platinization and Platinum Black

|

|

|

|

|

| Five Point Terminal Board. |

|

|

| |

|

|

|

|

|

| Each Terminal Will Accept |

|

|

| |

|

|

|

|

|

| #16 Gage Max. Wire |

|

|

| |

|

|

| Four Point Terminal Plate |

|

|

|

|

| ||

|

|

| with |

|

| SH |

|

| ||

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

| 1000 ft. max. |

| G | #2 Temp | (Note 5) |

|

|

|

|

|

|

| R |

| ||

|

|

|

|

|

| Note 3 |

| Compensator | ||

|

|

|

|

|

|

|

|

|

| |

RED | B |

|

|

|

| D |

| G | #1 Temp |

|

|

|

|

|

|

|

|

| |||

Temp. |

|

| A |

| D | B |

| R | Compensator | |

Comp. |

|

|

|

|

|

|

|

|

|

|

GREEN | D |

| B |

| C | Note 2 |

| W | Cell 2 (Note 5) | |

WHITE | C |

|

|

|

|

|

| K | Electrodes | |

|

|

|

|

|

| W |

|

| ||

Cell |

|

|

|

|

| C |

| Cell 1 |

| |

BLACK | A |

|

|

|

|

|

|

|

| |

|

|

|

| A |

| K | Electrodes | |||

Internal Cell Assembly |

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

| ||

Configuration | View of Junction Box Head | Coax Cable | Note 1 |

|

|

| ||||

|

|

| with Cap Removed | Shield |

|

|

| |||

|

|

|

|

|

|

| ||||

|

| Cell Assembly Connections |

| Conductivity/Resistivity |

| |||||

|

|

|

|

|

|

|

| |||

|

| I | II | III | IV V | VI |

| Analyzer |

| GND |

|

|

|

|

| ||||||

| 4905 | - | - | 333 | - X1 |

| Analyzer Input Connections | |||

|

|

|

|

|

|

| ||||

4973 I

4974 -

4908 I

4909 -

II | III |

| IV |

| V |

|

|

|

| ||

333 | - X1 | - |

|

|

|

| VI VII | ||||

II | III | IV |

| V |

| ||||||

- |

|

| 333 | - X1 |

|

|

|

|

|

| |

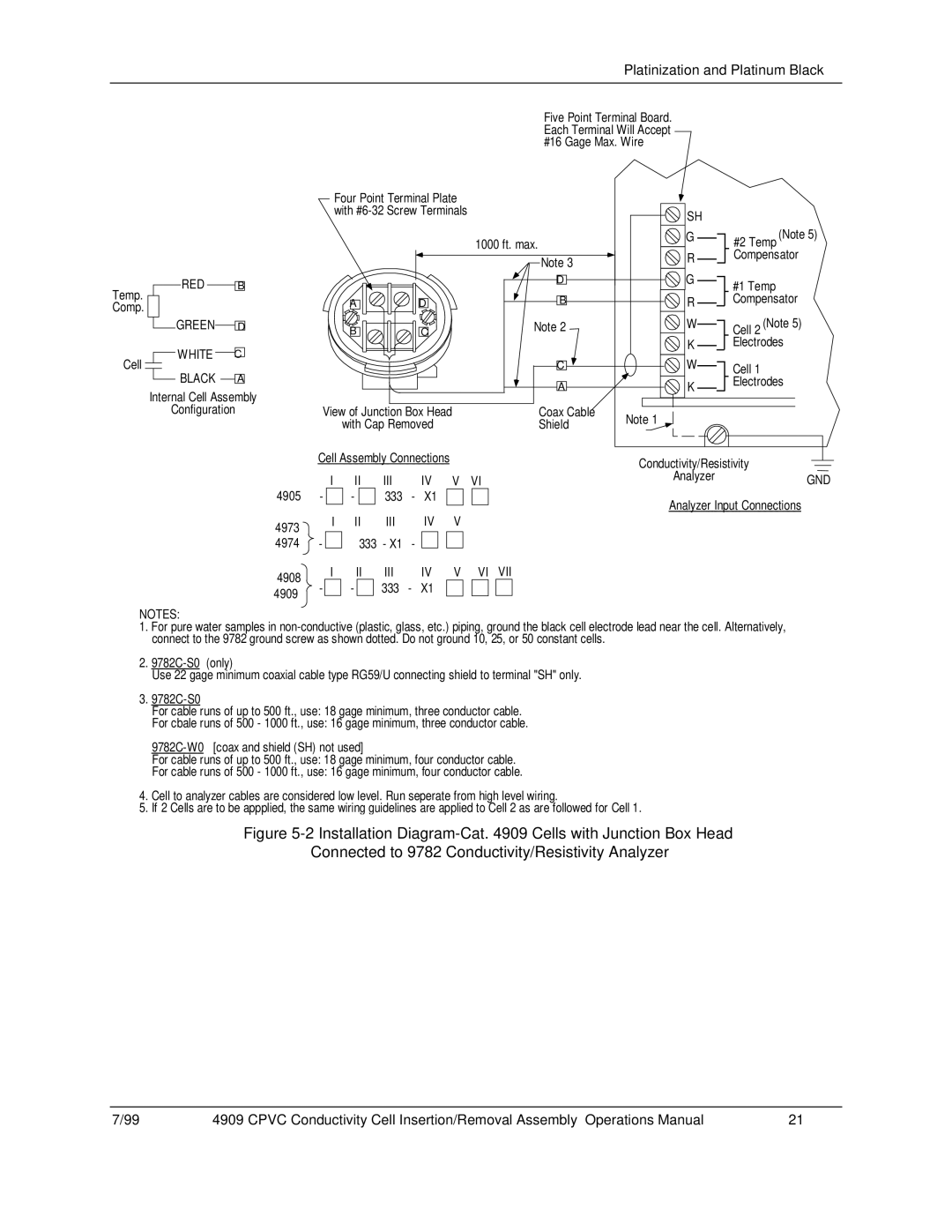

NOTES:

1.For pure water samples in

2.

Use 22 gage minimum coaxial cable type RG59/U connecting shield to terminal "SH" only.

3.

For cable runs of up to 500 ft., use: 18 gage minimum, three conductor cable.

For cbale runs of 500 - 1000 ft., use: 16 gage minimum, three conductor cable.

For cable runs of up to 500 ft., use: 18 gage minimum, four conductor cable.

For cable runs of 500 - 1000 ft., use: 16 gage minimum, four conductor cable.

4.Cell to analyzer cables are considered low level. Run seperate from high level wiring.

5.If 2 Cells are to be appplied, the same wiring guidelines are applied to Cell 2 as are followed for Cell 1.

Figure 5-2 Installation Diagram-Cat. 4909 Cells with Junction Box Head

Connected to 9782 Conductivity/Resistivity Analyzer

7/99 | 4909 CPVC Conductivity Cell Insertion/Removal Assembly– Operations Manual | 21 |