MicroDock II

Bump Test

5.Press C exit to return to normal operation.

For more information on setting up inlets, gas types, and con- centration levels, refer to Inlet Setup in the MicroDock II Base Station User Manual.

Bump Test

A bump test is performed to confirm that the detector is responding to gas, and that the audio and visual alarms are operational.

aCaution

Ensure the detector is not in a low battery state prior to performing a bump test.

To perform a bump test, complete the following:

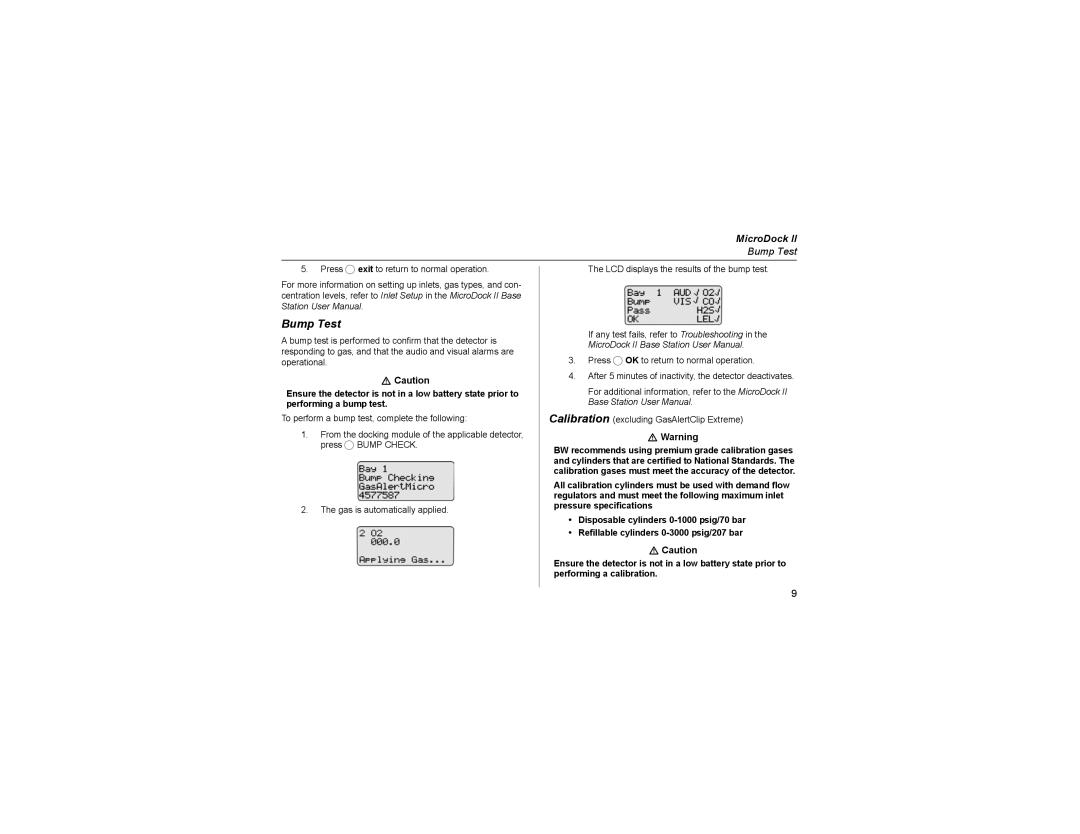

1.From the docking module of the applicable detector, press C BUMP CHECK.

2.The gas is automatically applied.

The LCD displays the results of the bump test.

If any test fails, refer to Troubleshooting in the

MicroDock II Base Station User Manual.

3.Press C OK to return to normal operation.

4.After 5 minutes of inactivity, the detector deactivates.

For additional information, refer to the MicroDock II Base Station User Manual.

Calibration (excluding GasAlertClip Extreme)

aWarning

BW recommends using premium grade calibration gases and cylinders that are certified to National Standards. The calibration gases must meet the accuracy of the detector.

All calibration cylinders must be used with demand flow regulators and must meet the following maximum inlet pressure specifications

•Disposable cylinders

•Refillable cylinders

aCaution

Ensure the detector is not in a low battery state prior to performing a calibration.

9