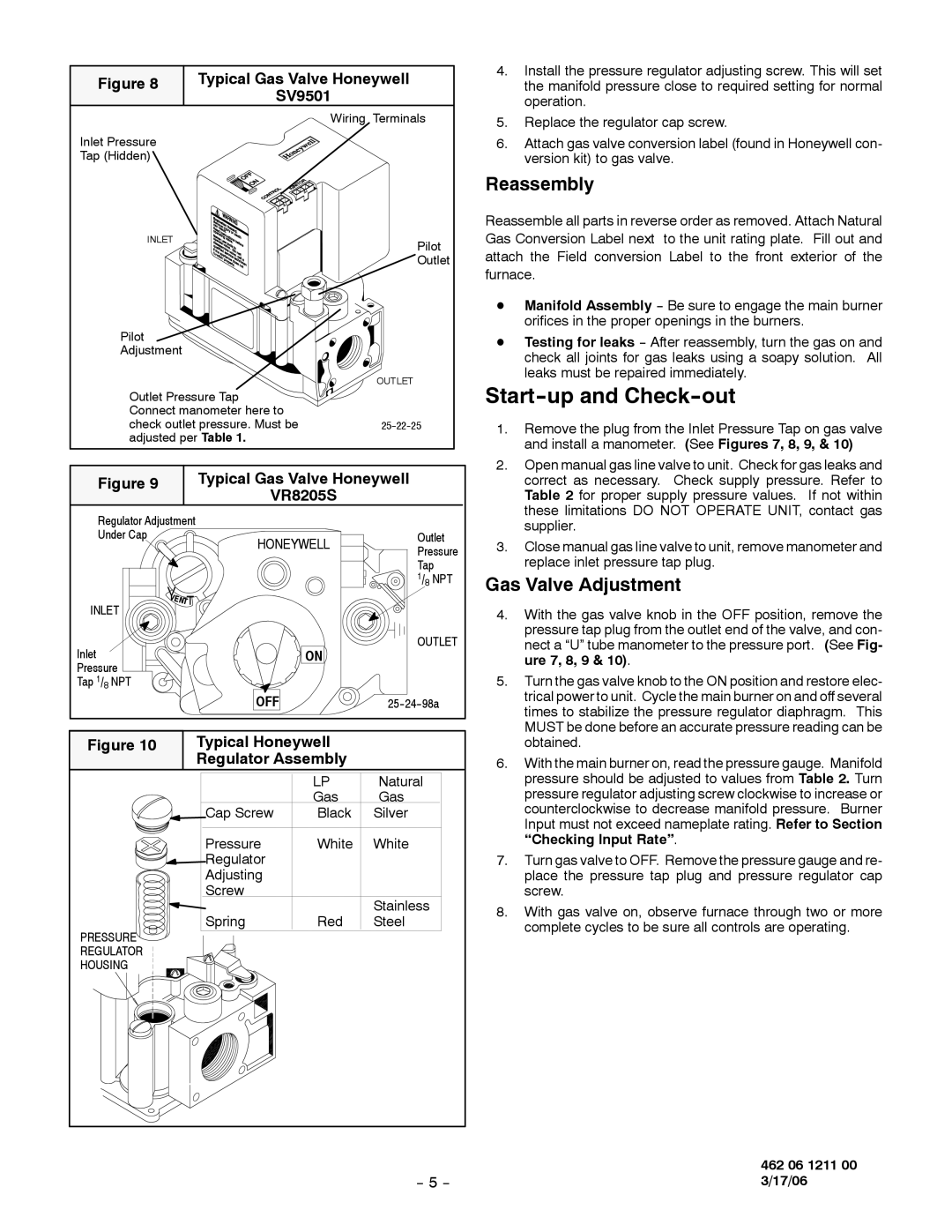

Figure 8 | Typical Gas Valve Honeywell | |

SV9501 | ||

| ||

| Wiring Terminals |

Inlet Pressure

Tap (Hidden)

INLET | Pilot |

| |

| Outlet |

Pilot

Adjustment

|

|

| OUTLET |

Outlet Pressure Tap |

|

| |

Connect manometer here to |

| ||

check outlet pressure. Must be | |||

adjusted per Table 1. |

|

| |

Figure 9 | Typical Gas Valve Honeywell | ||

| VR8205S |

| |

|

|

| |

Regulator Adjustment |

|

| |

Under Cap | HONEYWELL | Outlet | |

| Pressure | ||

|

|

| |

|

|

| Tap |

|

|

| 1/ NPT |

V |

|

| 8 |

T |

|

| |

INLET |

|

|

|

Inlet |

| ON | OUTLET |

|

| ||

Pressure |

|

|

|

Tap 1/ NPT |

|

|

|

8 |

|

|

|

| OFF |

| |

Figure 10 | Typical Honeywell |

| |

| Regulator Assembly |

| |

|

| LP | Natural |

|

| Gas | Gas |

| Cap Screw | Black | Silver |

| Pressure | White | White |

| Regulator |

|

|

| Adjusting |

|

|

| Screw |

| Stainless |

|

|

| |

PRESSURE | Spring | Red | Steel |

|

|

| |

REGULATOR |

|

|

|

HOUSING |

|

|

|

|

|

| |

4.Install the pressure regulator adjusting screw. This will set the manifold pressure close to required setting for normal operation.

5.Replace the regulator cap screw.

6.Attach gas valve conversion label (found in Honeywell con- version kit) to gas valve.

Reassembly

Reassemble all parts in reverse order as removed. Attach Natural Gas Conversion Label next to the unit rating plate. Fill out and attach the Field conversion Label to the front exterior of the furnace.

DManifold Assembly

DTesting for leaks

Start--up and Check--out

1.Remove the plug from the Inlet Pressure Tap on gas valve and install a manometer. (See Figures 7, 8, 9, & 10)

2.Open manual gas line valve to unit. Check for gas leaks and correct as necessary. Check supply pressure. Refer to Table 2 for proper supply pressure values. If not within these limitations DO NOT OPERATE UNIT, contact gas supplier.

3.Close manual gas line valve to unit, remove manometer and replace inlet pressure tap plug.

Gas Valve Adjustment

4.With the gas valve knob in the OFF position, remove the pressure tap plug from the outlet end of the valve, and con- nect a “U” tube manometer to the pressure port. (See Fig- ure 7, 8, 9 & 10).

5.Turn the gas valve knob to the ON position and restore elec- trical power to unit. Cycle the main burner on and off several times to stabilize the pressure regulator diaphragm. This MUST be done before an accurate pressure reading can be obtained.

6.With the main burner on, read the pressure gauge. Manifold pressure should be adjusted to values from Table 2. Turn pressure regulator adjusting screw clockwise to increase or counterclockwise to decrease manifold pressure. Burner Input must not exceed nameplate rating. Refer to Section “Checking Input Rate”.

7.Turn gas valve to OFF. Remove the pressure gauge and re- place the pressure tap plug and pressure regulator cap screw.

8.With gas valve on, observe furnace through two or more complete cycles to be sure all controls are operating.

462 06 1211 00 3/17/06