F-801MWH/-C, F-801MAH/-C specifications

The Hoshizaki F-801MAH/-C and F-801MWH/-C are high-performance ice machines designed for commercial use, particularly in restaurants, bars, and food service settings. These models are renowned for their reliability, efficiency, and strong production capabilities, making them ideal choices for businesses that require large quantities of ice on a regular basis.One of the standout features of the Hoshizaki F-801 models is their impressive ice production capacity. They can produce up to 800 pounds of cube ice every 24 hours, ensuring that businesses never run out of ice during peak periods. This high output is complemented by a large storage bin that can hold up to 600 pounds of ice, providing ample supply for busy environments.

In terms of technology, both the F-801MAH/-C and F-801MWH/-C employ Hoshizaki's unique air-cooled refrigeration system. This system enhances efficiency while minimizing energy consumption, making these machines environmentally friendly and cost-effective. The ice-making cycle is optimized, ensuring rapid production without compromising on the quality of the ice.

Additionally, the F-801 models feature a stainless steel exterior, ensuring durability and easy maintenance. The hygienic design reduces the risk of contamination, making these machines suitable for a variety of food service applications. The interiors are configured with rounded corners, allowing for easier cleaning and maintenance.

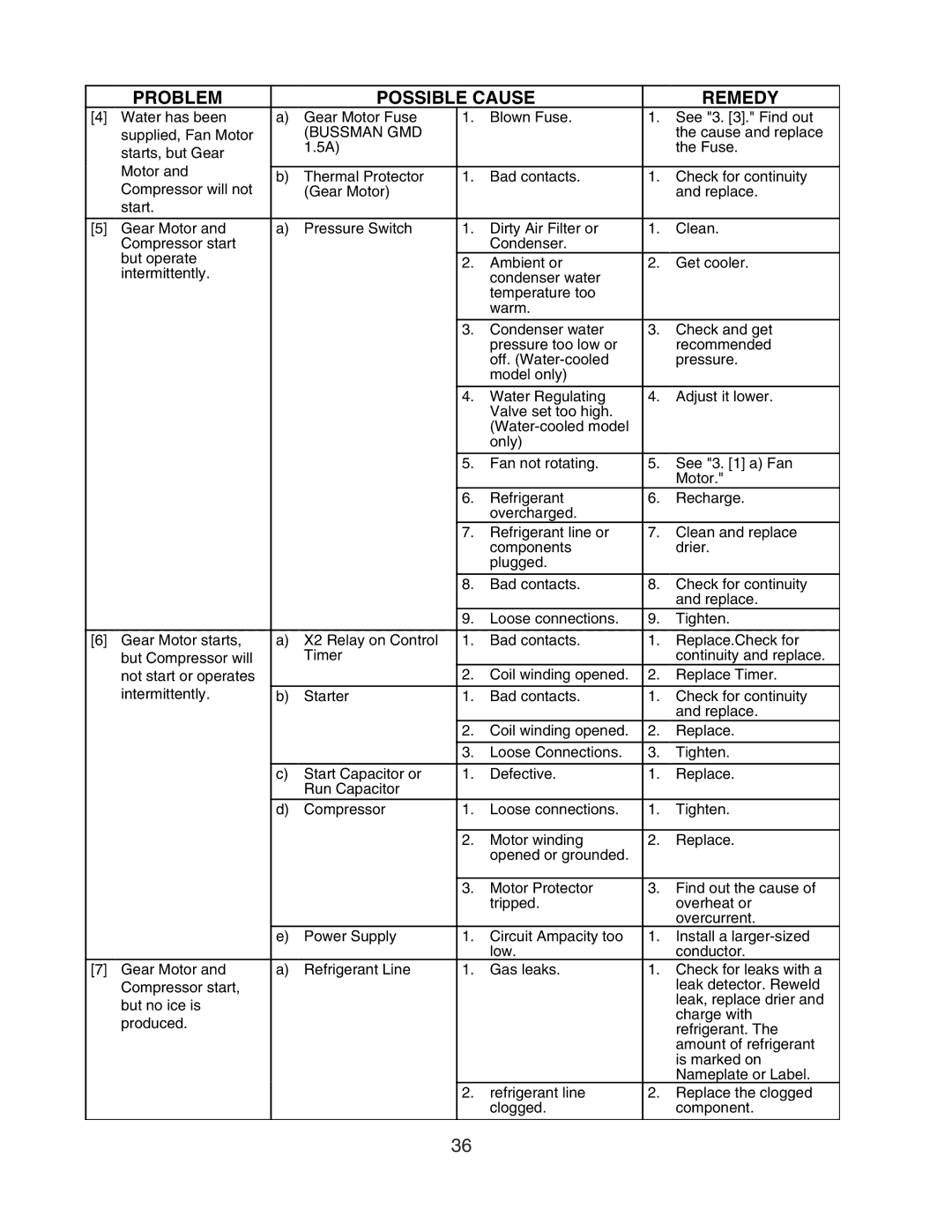

Another notable characteristic of the F-801MAH/-C and F-801MWH/-C is their self-diagnostic system which regularly monitors the machine's performance. This feature allows operators to identify and address potential issues before they lead to costly downtime, enhancing operational efficiency.

The machines also come with a built-in cleaning cycle, which aids in maintaining optimal performance and extending the lifespan of the units. This convenience means that operators can ensure consistent ice quality with minimal effort.

Overall, the Hoshizaki F-801MAH/-C and F-801MWH/-C ice machines represent a combination of advanced technology, robust performance, and user-friendly design. With their high production capabilities, energy efficiency, and ease of maintenance, they are excellent investments for any business requiring a reliable source of ice. Whether it is for cocktails at a bustling bar or for food preservation in a busy kitchen, these machines are equipped to meet diverse operational needs while delivering exceptional performance.