Installing the dryer.

Safety

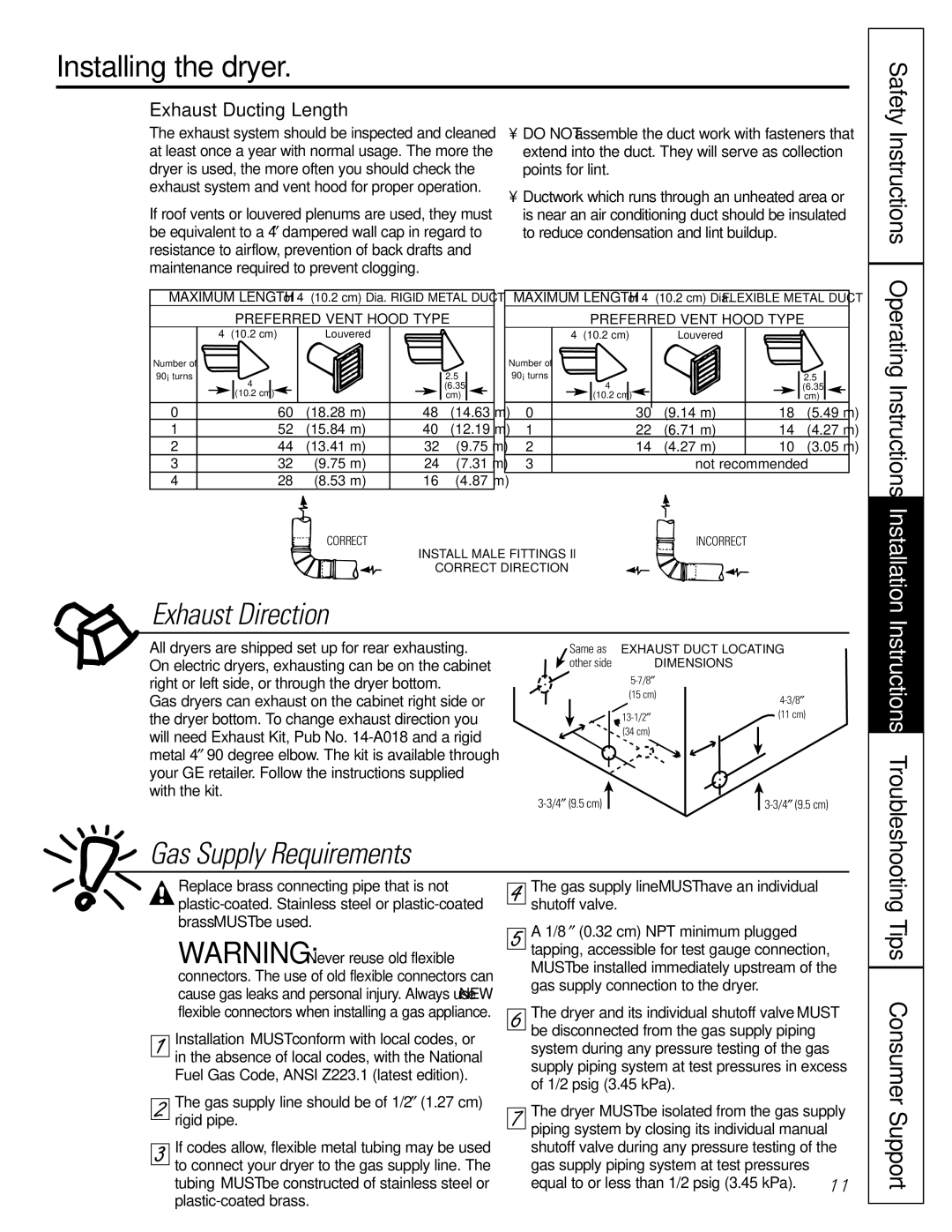

Exhaust Ducting Length

The exhaust system should be inspected and cleaned at least once a year with normal usage. The more the dryer is used, the more often you should check the exhaust system and vent hood for proper operation.

If roof vents or louvered plenums are used, they must be equivalent to a 4″ dampered wall cap in regard to resistance to airflow, prevention of back drafts and maintenance required to prevent clogging.

•DO NOT assemble the duct work with fasteners that extend into the duct. They will serve as collection points for lint.

•Ductwork which runs through an unheated area or is near an air conditioning duct should be insulated to reduce condensation and lint buildup.

Instructions

MAXIMUM LENGTH of 4“ (10.2 cm) Dia. RIGID METAL DUCT

PREFERRED VENT HOOD TYPE

|

| 4” (10.2 cm) |

|

|

| Louvered |

|

|

|

|

|

|

|

| ||

Number of |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

90° turns |

|

|

| 4” |

|

|

|

|

|

|

| 2.5” |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

| (6.35 |

|

|

|

| |

|

|

|

| (10.2 cm) |

|

|

|

|

|

|

| cm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

| 60’ | (18.28 m) | 48’ | (14.63 m) | ||||||||

1 |

|

|

|

| 52’ | (15.84 m) | 40’ | (12.19 m) | ||||||||

2 |

|

|

|

| 44’ | (13.41 m) | 32’ | (9.75 m) | ||||||||

3 |

|

|

|

| 32’ | (9.75 m) | 24’ | (7.31 m) | ||||||||

4 |

|

|

|

| 28’ | (8.53 m) | 16’ | (4.87 m) | ||||||||

MAXIMUM LENGTH of 4“ (10.2 cm) Dia. FLEXIBLE METAL DUCT

PREFERRED VENT HOOD TYPE

|

| 4” (10.2 cm) |

|

|

|

| Louvered |

|

|

|

|

|

|

| ||

Number of |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

90° turns |

|

|

| 4” |

|

|

|

|

|

|

|

| 2.5” |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

| (6.35 |

|

|

| |

|

|

|

| (10.2 cm) |

|

|

|

|

|

|

|

| cm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

0 |

|

|

|

| 30’ |

| (9.14 m) | 18’ | (5.49 m) | |||||||

|

|

|

|

| ||||||||||||

1 |

|

|

|

| 22’ |

| (6.71 m) | 14’ | (4.27 m) | |||||||

2 |

|

|

|

| 14’ |

| (4.27 m) | 10’ | (3.05 m) | |||||||

3 |

|

|

|

|

|

|

|

| not recommended | |||||||

Operating Instructions

CORRECT | INCORRECT |

INSTALL MALE FITTINGS IN

CORRECT DIRECTION

Exhaust Direction

Installation

All dryers are shipped set up for rear exhausting. On electric dryers, exhausting can be on the cabinet right or left side, or through the dryer bottom.

Gas dryers can exhaust on the cabinet right side or the dryer bottom. To change exhaust direction you will need Exhaust Kit, Pub No.

Same as EXHAUST DUCT LOCATING |

| |

other side | DIMENSIONS |

|

| ||

(15 cm) | ||

|

| |

| (11 cm) | |

(34 cm) |

|

|

| ||

Instructions Troubleshooting

Gas Supply Requirements

| Replace brass connecting pipe that is not |

| The gas supply line MUST have an individual |

| |

| 4 |

| |||

| shutoff valve. |

| |||

|

|

| |||

| brass MUST be used. |

| A 1/8″ (0.32 cm) NPT minimum plugged |

| |

| WARNING: Never reuse old flexible | 5 |

| ||

| tapping, accessible for test gauge connection, |

| |||

|

|

|

| ||

| connectors. The use of old flexible connectors can |

| MUST be installed immediately upstream of the | ||

|

| gas supply connection to the dryer. |

| ||

| cause gas leaks and personal injury. Always use NEW |

|

| ||

|

| The dryer and its individual shutoff valve MUST | |||

| flexible connectors when installing a gas appliance. |

| |||

| 6 | ||||

| Installation MUST conform with local codes, or | be disconnected from the gas supply piping |

| ||

|

|

| |||

1 |

| system during any pressure testing of the gas |

| ||

in the absence of local codes, with the National |

|

| |||

|

|

| |||

| Fuel Gas Code, ANSI Z223.1 (latest edition). |

| supply piping system at test pressures in excess | ||

|

| of 1/2 psig (3.45 kPa). |

| ||

| The gas supply line should be of 1/2″ (1.27 cm) |

|

| ||

|

|

|

| ||

2 |

| The dryer MUST be isolated from the gas supply | |||

rigid pipe. | 7 | ||||

| piping system by closing its individual manual |

| |||

|

|

| |||

| If codes allow, flexible metal tubing may be used |

| shutoff valve during any pressure testing of the | ||

3 |

| ||||

to connect your dryer to the gas supply line. The |

| gas supply piping system at test pressures |

| ||

|

|

| |||

| tubing MUST be constructed of stainless steel or |

| equal to or less than 1/2 psig (3.45 kPa). | 11 | |

|

|

|

| ||