SAFETY INSTRUCTIONS

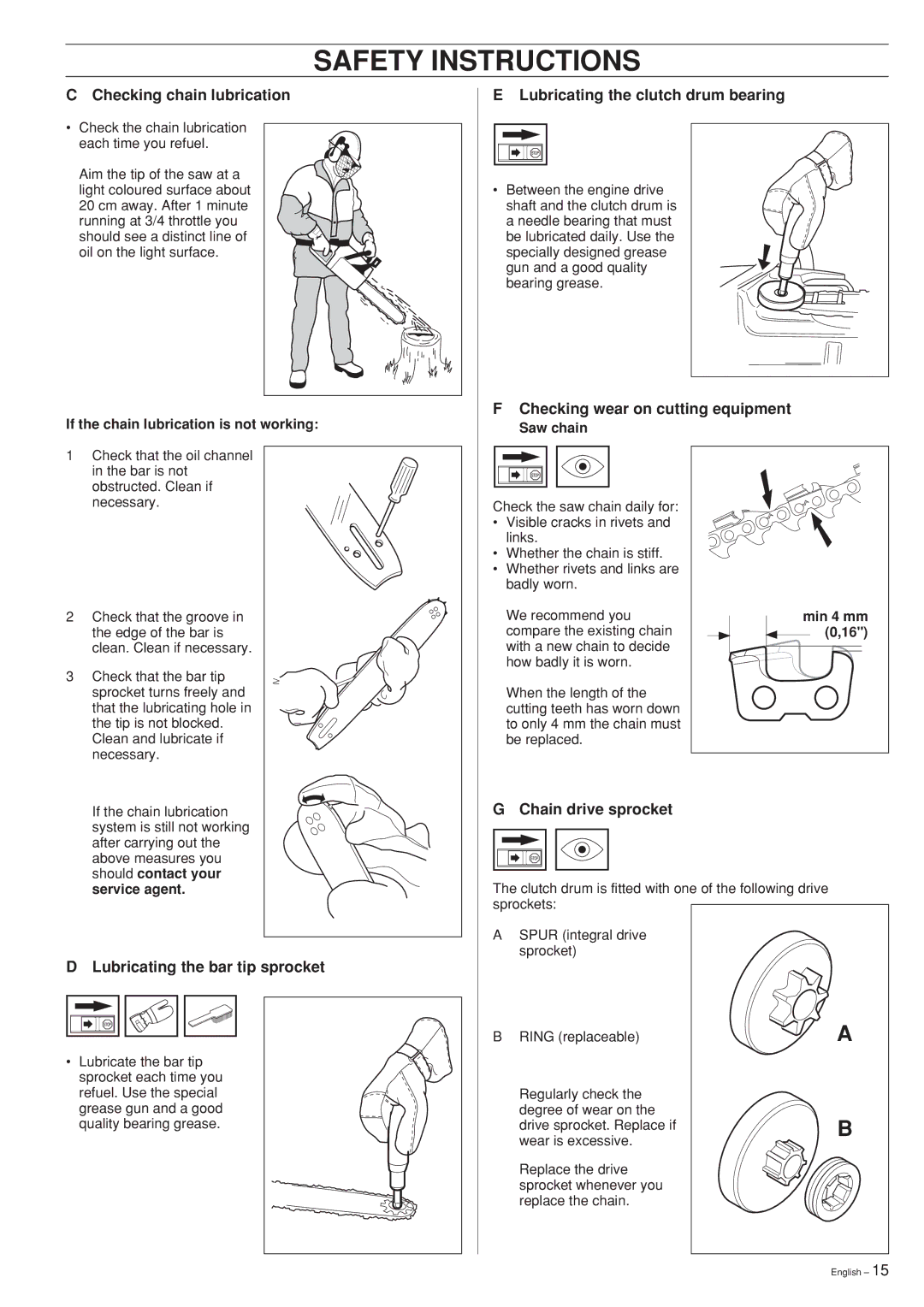

C Checking chain lubrication

•Check the chain lubrication

each time you refuel.

Aim the tip of the saw at a light coloured surface about 20 cm away. After 1 minute running at 3/4 throttle you should see a distinct line of oil on the light surface.

If the chain lubrication is not working:

E Lubricating the clutch drum bearing

•Between the engine drive shaft and the clutch drum is a needle bearing that must be lubricated daily. Use the specially designed grease gun and a good quality

bearing grease.

FChecking wear on cutting equipment

Saw chain

1Check that the oil channel in the bar is not obstructed. Clean if necessary.

2 Check that the groove in the edge of the bar is clean. Clean if necessary.

3 Check that the bar tip sprocket turns freely and that the lubricating hole in the tip is not blocked. Clean and lubricate if necessary.

Check the saw chain daily for:

•Visible cracks in rivets and links.

•Whether the chain is stiff.

•Whether rivets and links are badly worn.

We recommend you compare the existing chain with a new chain to decide how badly it is worn.

When the length of the cutting teeth has worn down to only 4 mm the chain must be replaced.

min 4 mm |

(0,16") |

If the chain lubrication system is still not working after carrying out the above measures you should contact your service agent.

D Lubricating the bar tip sprocket

• Lubricate the bar tip sprocket each time you refuel. Use the special grease gun and a good quality bearing grease.

G Chain drive sprocket

The clutch drum is fitted with one of the following drive sprockets:

ASPUR (integral drive sprocket)

B RING (replaceable) | A |

Regularly check the |

|

degree of wear on the | B |

drive sprocket. Replace if | |

wear is excessive. |

|

Replace the drive sprocket whenever you replace the chain.

English – 15