SERVICE AND ADJUSTMENTS

•Road test tractor for proper stopping distance as stated above. Readjust if necessary. If stopping distance is still greater than six (6) feet in highest gear, further maintenance is necessary. Contact your nearest au- thorized service center/department.

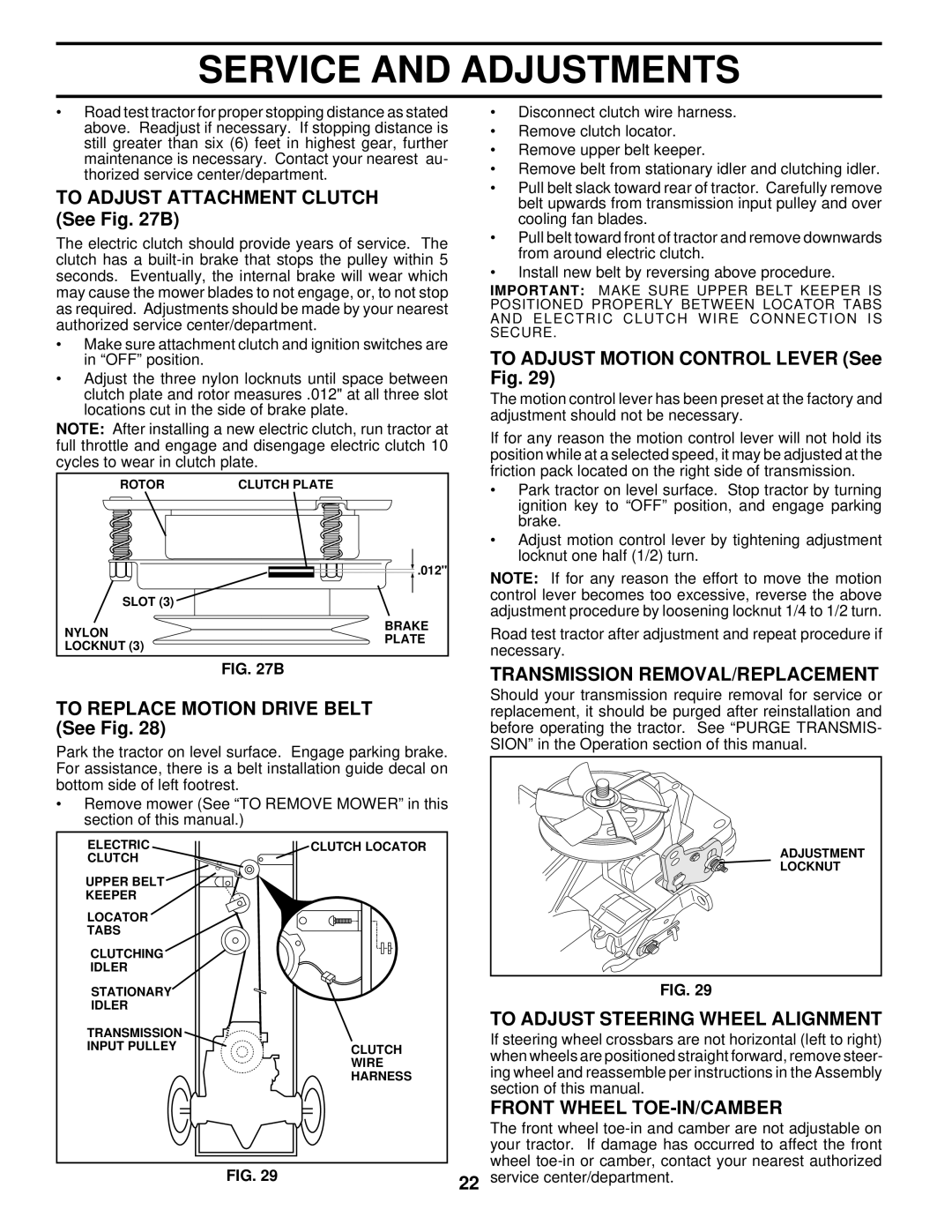

TO ADJUST ATTACHMENT CLUTCH (See Fig. 27B)

The electric clutch should provide years of service. The clutch has a

•Make sure attachment clutch and ignition switches are in “OFF” position.

•Adjust the three nylon locknuts until space between clutch plate and rotor measures .012" at all three slot locations cut in the side of brake plate.

NOTE: After installing a new electric clutch, run tractor at full throttle and engage and disengage electric clutch 10 cycles to wear in clutch plate.

ROTOR | CLUTCH PLATE | |

| .012" | |

SLOT (3) |

| |

NYLON | BRAKE | |

PLATE | ||

LOCKNUT (3) | ||

|

FIG. 27B

•Disconnect clutch wire harness.

•Remove clutch locator.

•Remove upper belt keeper.

•Remove belt from stationary idler and clutching idler.

•Pull belt slack toward rear of tractor. Carefully remove belt upwards from transmission input pulley and over cooling fan blades.

•Pull belt toward front of tractor and remove downwards from around electric clutch.

•Install new belt by reversing above procedure.

IMPORTANT: MAKE SURE UPPER BELT KEEPER IS POSITIONED PROPERLY BETWEEN LOCATOR TABS AND ELECTRIC CLUTCH WIRE CONNECTION IS SECURE.

TO ADJUST MOTION CONTROL LEVER (See Fig. 29)

The motion control lever has been preset at the factory and adjustment should not be necessary.

If for any reason the motion control lever will not hold its position while at a selected speed, it may be adjusted at the friction pack located on the right side of transmission.

•Park tractor on level surface. Stop tractor by turning ignition key to “OFF” position, and engage parking brake.

•Adjust motion control lever by tightening adjustment locknut one half (1/2) turn.

NOTE: If for any reason the effort to move the motion control lever becomes too excessive, reverse the above adjustment procedure by loosening locknut 1/4 to 1/2 turn.

Road test tractor after adjustment and repeat procedure if necessary.

TRANSMISSION REMOVAL/REPLACEMENT

TO REPLACE MOTION DRIVE BELT (See Fig. 28)

Park the tractor on level surface. Engage parking brake. For assistance, there is a belt installation guide decal on bottom side of left footrest.

•Remove mower (See “TO REMOVE MOWER” in this section of this manual.)

Should your transmission require removal for service or replacement, it should be purged after reinstallation and before operating the tractor. See “PURGE TRANSMIS- SION” in the Operation section of this manual.

ELECTRIC

CLUTCH

UPPER BELT KEEPER

LOCATOR

TABS

CLUTCHING IDLER

STATIONARY IDLER

TRANSMISSION INPUT PULLEY

CLUTCH LOCATOR |

CLUTCH |

WIRE |

HARNESS |

ADJUSTMENT |

LOCKNUT |

FIG. 29

TO ADJUST STEERING WHEEL ALIGNMENT

If steering wheel crossbars are not horizontal (left to right) when wheels are positioned straight forward, remove steer- ing wheel and reassemble per instructions in the Assembly section of this manual.

FRONT WHEEL TOE-IN/CAMBER

The front wheel

FIG. 29 | 22 |

|

service center/department.