IGSS-ESS, ESSS-0303 specifications

The Hussman ESSS-0303 and IGSS-ESS are revolutionary products in the world of commercial refrigeration, known for their ability to deliver energy-efficient performance while ensuring optimal food preservation. These systems feature cutting-edge technology that caters to the needs of supermarkets, convenience stores, and other retail environments where refrigeration is crucial.One of the primary features of the Hussman ESSS-0303 is its advanced energy management capabilities. The system is equipped with intelligent controls that analyze energy consumption patterns, optimizing performance in real time. This not only helps to reduce operational costs but also contributes to sustainability efforts by minimizing energy waste.

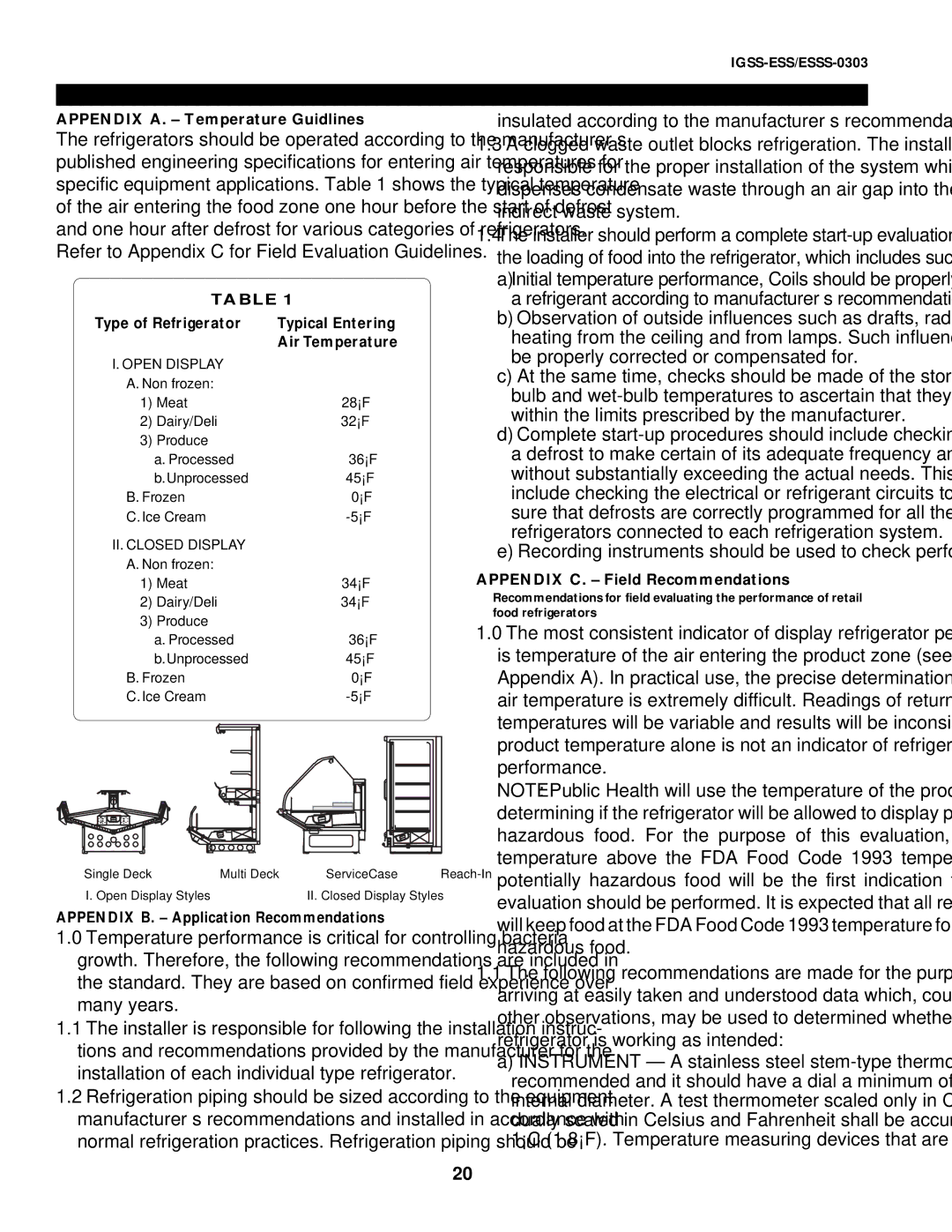

Another significant aspect of the ESSS-0303 is its ability to maintain precise temperature control. This is achieved through a combination of high-quality insulation and advanced refrigeration technology, which ensures that products remain fresh for longer periods. The unit offers temperature ranges specifically designed for various applications, whether it be for dairy products, frozen foods, or fresh produce.

The Hussman IGSS-ESS, on the other hand, is designed to integrate seamlessly with existing refrigeration setups, allowing for a smooth transition to newer technologies. Its modular design allows businesses to easily expand their refrigeration capabilities without the need for extensive renovations. In addition, the IGSS-ESS features remote monitoring capabilities, which enables store managers to track performance and diagnose potential issues from a distance, ensuring minimal downtime.

These systems are also built with user-friendliness in mind. The intuitive control interface allows for easy programming and adjustments, empowering staff to efficiently manage the refrigeration environment. Furthermore, Hussman has made durability a priority; both the ESSS-0303 and IGSS-ESS are constructed from robust materials, ensuring longevity even in high-demand retail settings.

In summary, the Hussman ESSS-0303 and IGSS-ESS offer enhanced energy efficiency, precise temperature control, integration capabilities, remote monitoring, and user-friendly interfaces. These characteristics make them ideal choices for retailers seeking to optimize their refrigeration solutions while maintaining product quality and reducing energy costs. As businesses continue to prioritize sustainability and efficiency, the Hussman range stands out as a reliable partner in commercial refrigeration technology.