-1" wrench

-vise

-Teflon tape

1.Open prime valve, (ref# 36) in order to release pressure from the material side of pump.

2.Remove pressure control knob, (ref# 75) and pull P.C. stem, (ref# 78) out to internal stop, thereby releasing hydraulic pressure.

3.Disconnect outgo tee, (ref# 35) from outgo swivel, (ref# 32) on the outgo valve.

4.Remove outgo valve from machine by turning counter clockwise.

5.Invert valve and secure upper part of valve, (ref# 31) in vise.

6.Remove lower half of valve, (ref# 27).

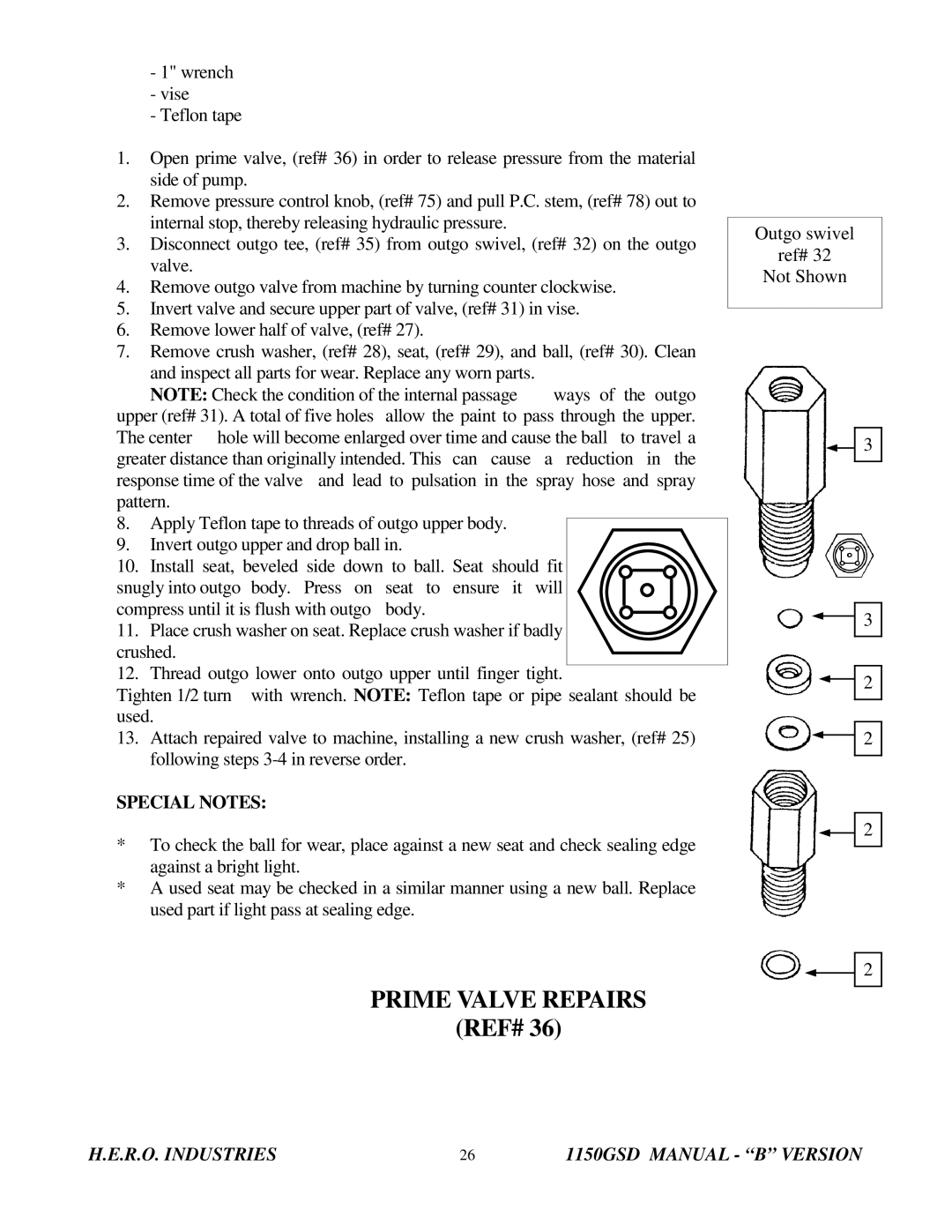

7.Remove crush washer, (ref# 28), seat, (ref# 29), and ball, (ref# 30). Clean and inspect all parts for wear. Replace any worn parts.

NOTE: Check the condition of the internal passage ways of the outgo upper (ref# 31). A total of five holes allow the paint to pass through the upper. The center hole will become enlarged over time and cause the ball to travel a greater distance than originally intended. This can cause a reduction in the response time of the valve and lead to pulsation in the spray hose and spray pattern.

8.Apply Teflon tape to threads of outgo upper body.

9.Invert outgo upper and drop ball in.

10.Install seat, beveled side down to ball. Seat should fit snugly into outgo body. Press on seat to ensure it will

compress until it is flush with outgo body.

11.Place crush washer on seat. Replace crush washer if badly crushed.

12.Thread outgo lower onto outgo upper until finger tight.

Tighten 1/2 turn with wrench. NOTE: Teflon tape or pipe sealant should be used.

13.Attach repaired valve to machine, installing a new crush washer, (ref# 25) following steps

SPECIAL NOTES:

*To check the ball for wear, place against a new seat and check sealing edge against a bright light.

*A used seat may be checked in a similar manner using a new ball. Replace used part if light pass at sealing edge.

PRIME VALVE REPAIRS

(REF# 36)

Outgo swivel

ref# 32

Not Shown

3 |

3 |

2 |

2 |

2 |

2 |

H.E.R.O. INDUSTRIES | 26 | 1150GSD MANUAL - “B” VERSION |