PUMP OPTION DESCRIPTION CHART

|

| X | PACKING MATERIAL | (PACKINGS ARE UPPER AND LOWER UNLESS NOTED) | |||||||||||||||||

| 3 | Glass filled PTFE |

| P | |||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| C |

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PLUNGER TYPE |

| G | R PTFE / | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PTFE (lower) | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

PACKING MATERIAL |

|

|

|

|

|

|

|

|

|

|

|

| SPRING ARRANGEMENT | SPRING ARRANGEMENT |

| PLUNGER TYPE | |||||

|

|

|

|

|

|

|

|

|

|

|

| 4 | Multiple Wave Spring w/ |

| 3 Hardened Stainless Steel w/ | ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 316 Stainless Steel Balls |

| Hard Chrome Plating |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 7 | Multiple Wave Spring w/ |

| B Hardened Stainless Steel w/ | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 440 Stainless Steel Balls |

| Ceramic Coating |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GENERAL DESCRIPTION

![]()

![]() WARNING HAZARDOUS PRESSURE. Do not exceed maxi- mum operating pressure of 3300 p.s.i. (228 bar) at 150 p.s.i. (10.3 bar) inlet air pressure.

WARNING HAZARDOUS PRESSURE. Do not exceed maxi- mum operating pressure of 3300 p.s.i. (228 bar) at 150 p.s.i. (10.3 bar) inlet air pressure.

PUMP RATIO X | = | MAXIMUM PUMP |

INLET PRESSURE TO PUMP MOTOR | FLUID PRESSURE |

Pump ratio is an expression of the relationship between the pump motor area and the lower pump end area. EXAMPLE: When 150 p.s.i. (10.3 bar) inlet pressure is supplied to the motor of a 6:1 ratio pump it will develop a maximum of 750 p.s.i. (52 bar) fluid pressure (at no flow) - as the fluid control is opened, the flow rate will in- crease as the motor cycle rate increases to keep up with the demand.

![]()

![]() WARNING Refer to general information sheet for additional safety precautions and important information.

WARNING Refer to general information sheet for additional safety precautions and important information.

ξThe

ξThe motor is connected to the lower pump end by a spacer section. This allows for lubrication of the upper packing gland and prevents motor contamination because of normal wear and eventual leakage through the material packing gland. Be sure the solvent cup is ade- quately filled with lubricant to protect the upper packings and insure longest service life.

TROUBLE SHOOTING

Pump problems can occur in either the Air Motor Section or the Lower Pump End Section, use these basic guidelines to help determine which section is affected.

If the pump will not cycle.

ξBe certain to first check for

ξRefer to the motor manual for trouble shooting if the pump does not

cycle and / or air leaks from the air motor.

If the pump cycles but does not deliver material.

ξRefer to the lower pump end manual for further trouble shooting.

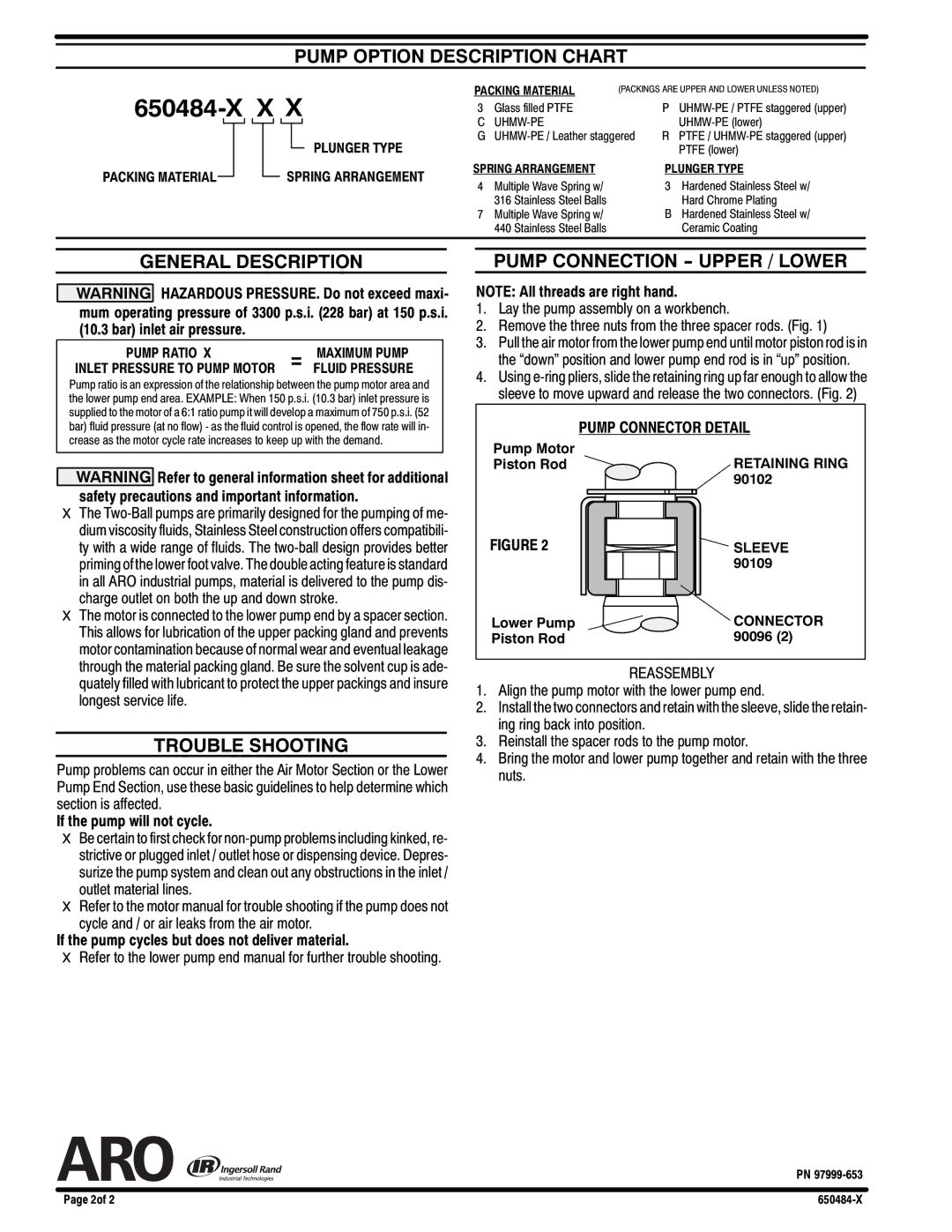

PUMP CONNECTION - UPPER / LOWER

NOTE: All threads are right hand.

1.Lay the pump assembly on a workbench.

2.Remove the three nuts from the three spacer rods. (Fig. 1)

3.Pull the air motor from the lower pump end until motor piston rod is in the “down” position and lower pump end rod is in “up” position.

4.Using

PUMP CONNECTOR DETAIL

Pump Motor

Piston RodRETAINING RING

90102

FIGURE 2 | SLEEVE |

| 90109 |

Lower Pump | CONNECTOR |

Piston Rod | 90096 (2) |

REASSEMBLY

1.Align the pump motor with the lower pump end.

2.Install the two connectors and retain with the sleeve, slide the retain- ing ring back into position.

3.Reinstall the spacer rods to the pump motor.

4.Bring the motor and lower pump together and retain with the three nuts.

PN

Page 2of 2 |