ACCESSORIES

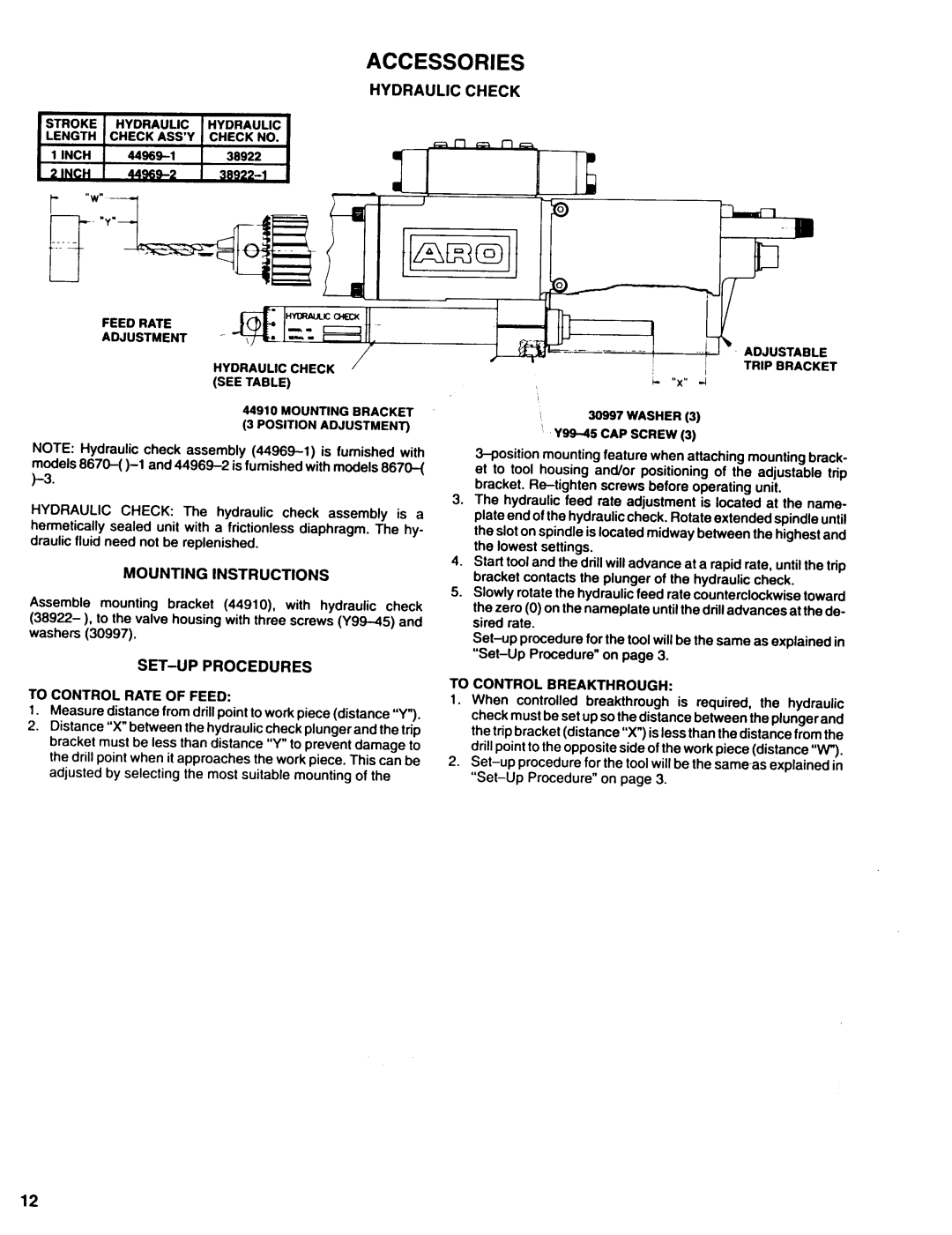

HYDRAULIC CHECK

44910 MOUNTING BRACKET (3 POSITION ADJUSTMENT)

NOTE: Hydraulic check assembly

HYDRAULIC CHECK: The hydraulic check assembly is a hermetically sealed unit with a frictionless diaphragm. The hy- draulic fluid need not be replenished.

MOUNTING INSTRUCTIONS

Assemble mounting bracket (44910) with hydraulic check

SET-UP PROCEDURES

TO CONTROL RATE OF FEED:

1.Measure distance from drill point to work piece (distance “Y”).

2.Distance “X”between the hydraulic check plungerand the trip bracket must be less than distance “Y”to prevent damage to the drill point when it approaches the work piece. This can be adjusted by selecting the most suitable mounting of the

TRIP BRACKET

,39997 WASHER (3)

’

3.The hydraulic feed rate adjustment is located at the name- plate end of the hydraulic check. Rotate extended spindle until the slot on spindle is located midway between the highest and the lowest settings.

4.Start tool and the drill will advance at a rapid rate, until the trip bracket contacts the plunger of the hydraulic check.

5.Slowly rotate the hydraulic feed rate counterclockwise toward the zero (0) on the nameplate until the drill advances at the de- sired rate.

TO CONTROL BREAKTHROUGH:

1.When controlled breakthrough is required, the hydraulic check must be set up so the distance between the plungerand the trip bracket (distance “X”)is less than the distance from the drill point to the opposite side of the work piece (distance “W).

2.

12