MOTOR SECTION

DISASSEMBLY

a.Remove motor from tool as outlined on page 4. Remove motor assembly from housing as outlined in paragraph “a”of gear- ing disassembly.

b.Remove retaining ring

NOTE: It is suggested that brass blocks be used in a vise or some other suitable fixture to clamp on splines of rotor to keep from turning while removing or tightening nut (44980). Care must be exercised so as not to damage splines of rotor shaft.

c.Grasp cylinder in one hand and tap splined end of rotor with a soft face hammer; motor will come apart.

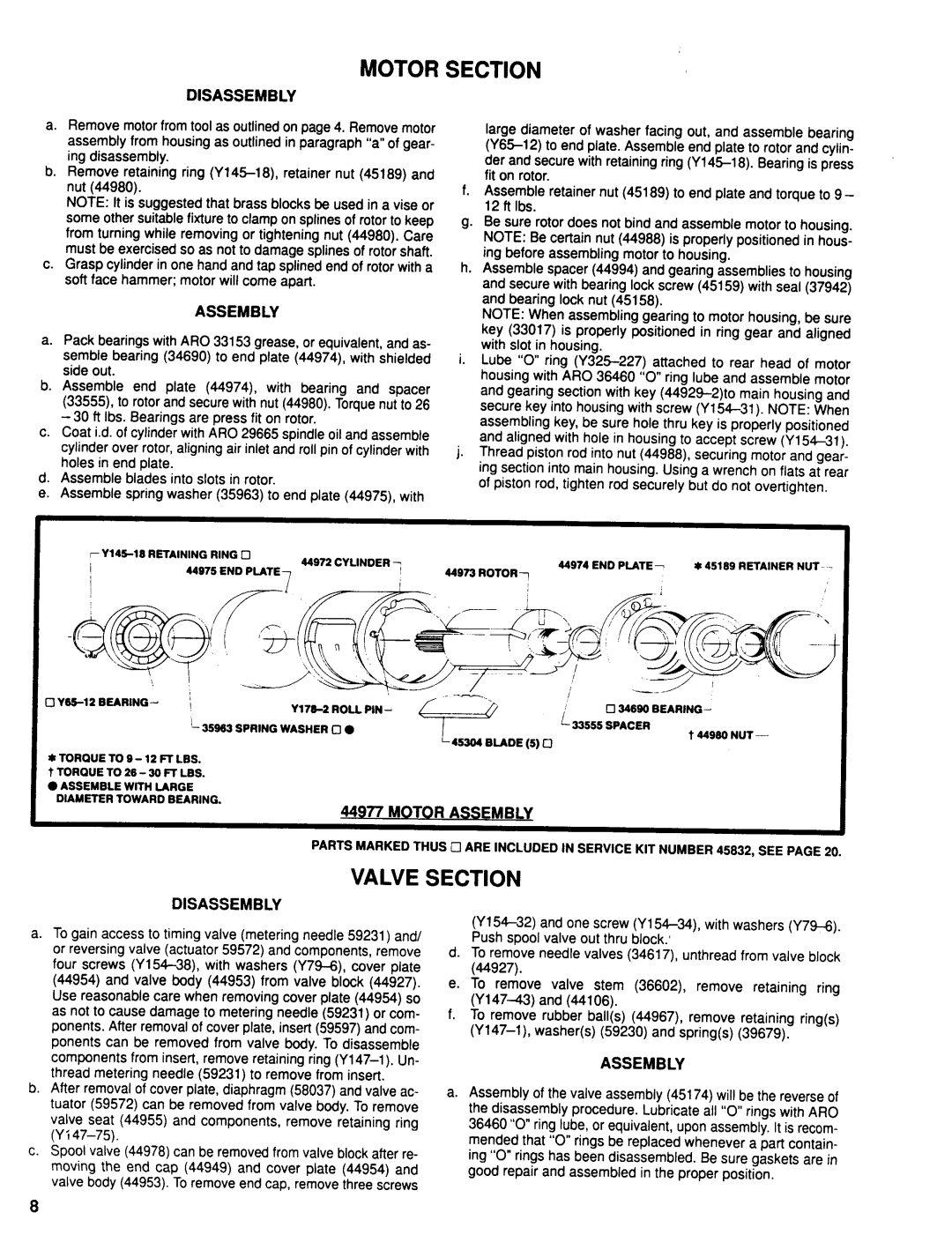

ASSEMBLY

a.Pack bearings with ARO 33153 grease, or equivalent, and as- semble bearing (34690) to end plate (44974) with shielded side out.

b.Assemble end plate (44974), with bearing and spacer (33555), to rotor and secure with nut (44980). Torque nut to 26 - 30 ft Ibs. Bearings are press fit on rotor.

c.Coat i.d. of cylinder with ARO 29665 spindle oil and assemble cylinder over rotor, aligning air inlet and roll pin of cylinder with holes in end plate.

d.Assemble blades into slots in rotor.

e.Assemble spring washer (35963) to end plate (44975), with

large diameter of washer facing out, and assemble bearing

f.Assemble retainer nut (45189) to end plate and torque to 9 - 12 ft Ibs.

g.Be sure rotor does not bind and assemble motor to housing. NOTE: Be certain nut (44988) is properly positioned in hous- ing before assembling motor to housing.

h.Assemble spacer (44994) and gearing assemblies to housing and secure with bearing lock screw (45159) with seal (37942) and bearing lock nut (45158).

NOTE: When assembling gearing to motor housing, be sure key (33017) is properly positioned in ring gear and aligned with slot in housing.

i.Lube “0” ring

j.Thread piston rod into nut (44988) securing motor and gear- ing section into main housing. Using a wrench on flats at rear of piston rod, tighten rod securely but do not overtighten.

44977 MOTOR ASSEMBLY

PARTS MARKED THUS Cl ARE INCLUDED IN SERVICE KIT NUMBER 45632, SEE PAGE 20.

VALVE SECTION

DISASSEMBLY

a.To gain access to timing valve (metering needle 59231) and/ or reversing valve (actuator 59572) and components, remove four screws

b.After removal of cover plate, diaphragm (58037) and valve ac- tuator (59572) can be removed from valve body. To remove

valve seat (44955) and components, remove retaining ring

c.Spool valve (44978) can be removed from valve block after re- moving the end cap (44949) and cover plate (44954) and valve body (44953). To remove end cap, remove three screws

d.To remove needle valves (34617) unthread from valve block (44927).

e.To remove valve stem (36602), remove retaining ring (Y14743) and (44106).

f.To remove rubber ball(s) (44967) remove retaining ring(s)

ASSEMBLY

a.Assembly of the valve assembly (45174) will be the reverse of the disassembly procedure. Lubricate all “0”rings with ARO 36460 “0”ring lube, or equivalent, upon assembly. It is recom-

mended that “0”rings be replaced whenever a part contain- ing "0" rings has been disassembled. Be sure gaskets are in good repair and assembled in the proper position.

8