PLACING TOOL IN SERVICE

CONTROLLER INFORMATION

Do not attempt to disassemble the Controller.

The Controller is available only as a unit and is guaranteed for the life of the tool if it is not abused.

Prior to assembly, carefully inspect the Controller Assembly for nicks, gouges and dents. Replace it with a new Controller Assembly if necessary. Test the free speed before applying a blade.

SAW BLADES

Removal

1.Insert a screwdriver into the 3/8” (9.5 mm) sprag hole of the Saw Blade to keep the Arbor from rotating.

In the following step, the Saw Blade Flange Bolt has a

2.Using a wrench on the flats of the Bolt, unscrew and remove the Saw Blade Flange Bolt.

3.Remove the Saw Blade Flange from the Saw Blade.

4.Retract the Swing Guard and withdraw the Blade through the Base.

Installation

1.Retract the Swing Guard and insert the Blade up through the Base, making sure the teeth on the Blade point in the direction in which the Blade will rotate (clockwise when facing the blade side of the tool).

2.Slip the Blade over the Arbor, aligning the two holes in the Blade with the corresponding holes in the flange on the Arbor.

3.Locate the Saw Blade Flange on the Arbor so the pins enter the holes in the Blade and Arbor Flange.

In the following step, the Saw Blade Flange Bolt has a

4.Screw the Saw Blade Flange Bolt into the end of the Blade Arbor.

5.Use a screwdriver inserted into the 3/8” (9.5 mm) sprag hole in the Saw Blade to keep the Arbor from rotating. Using the a wrench on the flats of the Bolt, tighten the Bolt between 70 and 75

Setting the Depth of Cut

1.Loosen the Depth Gauge Knob.

2.Grasp the Handle with one hand and hold the Base with the other.

3.Lift the motor and Guard from the Base until the distance from the bottom face of the Base and the lowest point on the Blade is equal to the depth desired.

4.Securely tighten the Depth Gauge Knob.

Setting the Angle of Cut

1.Loosen the two Tilt Sector Thumb Screws.

2.Tilt the motor and Guard on the Base until the desired setting is obtained as shown on the scale scribed on the edge of the Front Tilt Sector.

3.Tighten the two Tilt Sector Thumb Screws securely.

Sighting and Sawing

1.Open the throttle wide by squeezing the Throttle Lever in the Handle.

2.Align the mark to be followed with the pointer on the Yoke Pivot, and push the Saw forward. The Swing Guard will retract into the Stationary Guard as the Blade enters the material to be cut.

3.When the cut is finished, release the Throttle Lever and lift the Saw from the work. The Swing Guard will immediately swing out of the Stationary Guard to cover the Saw Blade.

Abrasive Blades

For cutting ferrous and nonferrous materials, Abrasive Blades are recommended. These Blades require the use of an Inner Blade Flange, Outer Blade Flange and a longer Blade Flange Bolt. (See parts list.)

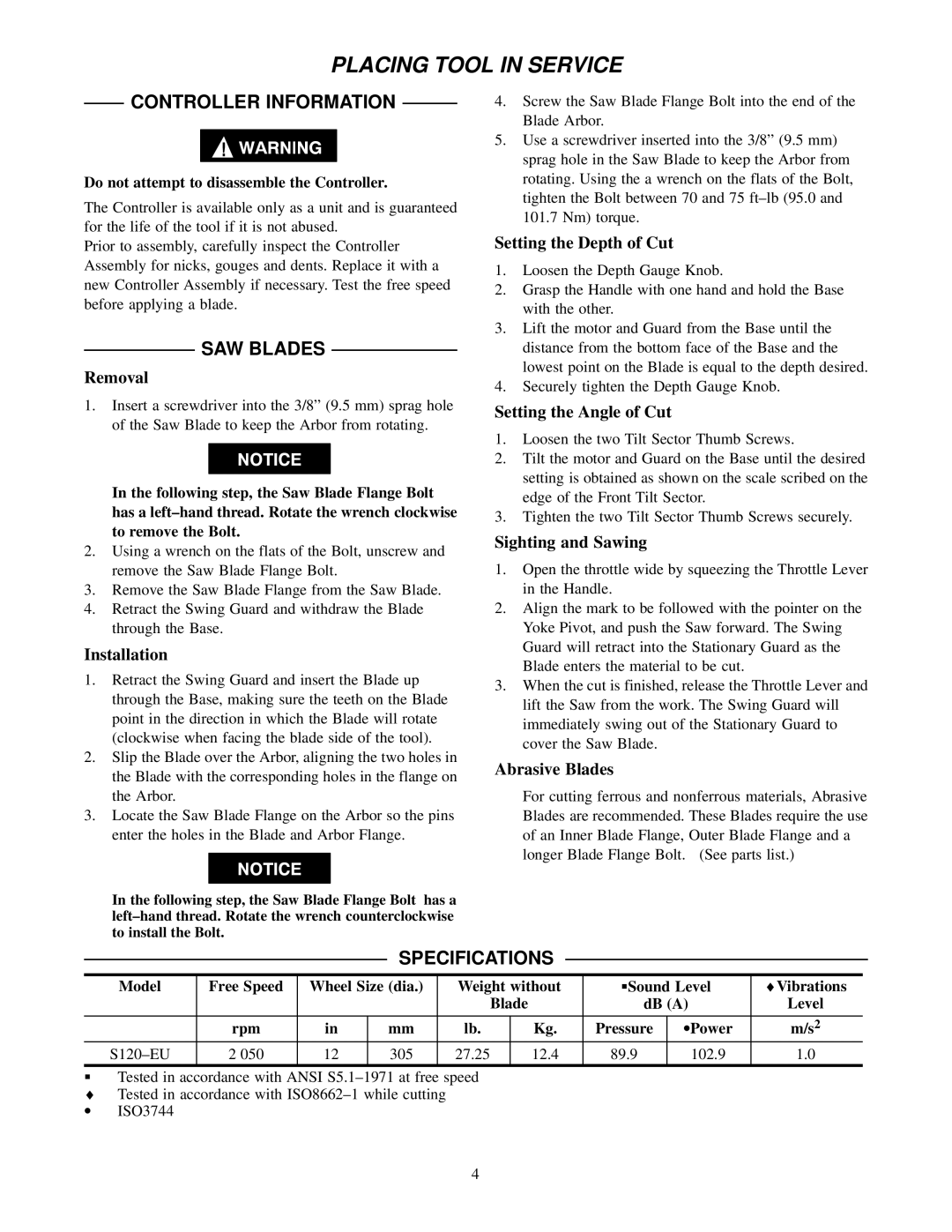

SPECIFICATIONS

Model | Free Speed | Wheel Size (dia.) | Weight without | GSound Level | ♦ Vibrations | ||||

|

|

|

|

| Blade | dB (A) | Level | ||

|

|

|

|

|

|

|

|

|

|

| rpm | in | mm | lb. |

| Kg. | Pressure | • Power | m/s2 |

| 2 050 | 12 | 305 | 27.25 |

| 12.4 | 89.9 | 102.9 | 1.0 |

GTested in accordance with ANSI

♦ Tested in accordance with

• ISO3744

4