SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

ELECTRICAL CONNECTIONS

trap is required by code, it should have a flow capacity of 5 gallons per minute.

WATER SUPPLY CONNECTION: Ensure that you have read the section entitled “PLUMBING THE DISHMACHINE” above before proceeding. Cold water supply must be a minimum of 70°F with a capacity of 180 gallons per hour at

In areas where the water pressure fluctuates or is greater than the recommended pressure, it is suggested that a water pres- sure regulator be installed.

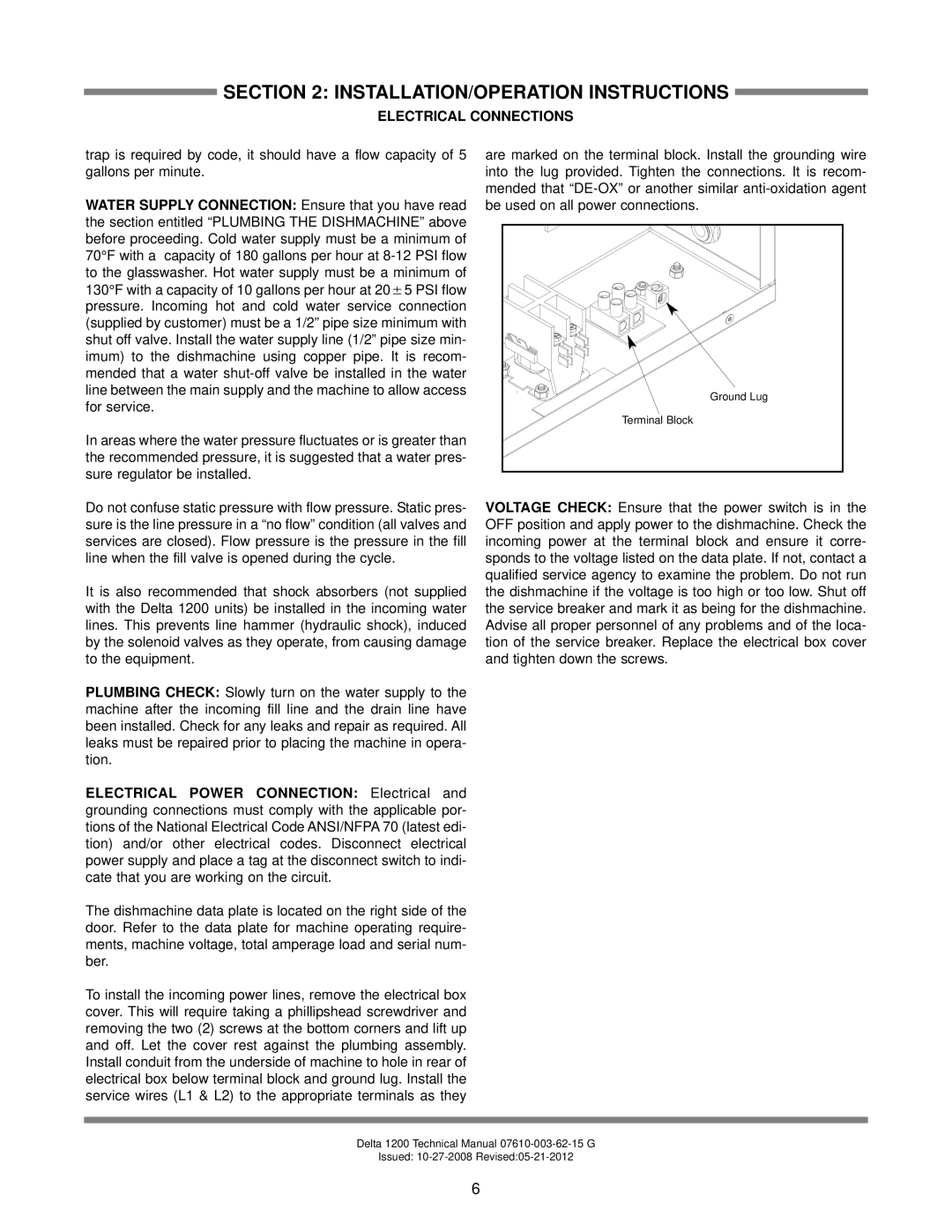

are marked on the terminal block. Install the grounding wire into the lug provided. Tighten the connections. It is recom- mended that

Ground Lug |

Terminal Block |

Do not confuse static pressure with flow pressure. Static pres- sure is the line pressure in a “no flow” condition (all valves and services are closed). Flow pressure is the pressure in the fill line when the fill valve is opened during the cycle.

It is also recommended that shock absorbers (not supplied with the Delta 1200 units) be installed in the incoming water lines. This prevents line hammer (hydraulic shock), induced by the solenoid valves as they operate, from causing damage to the equipment.

PLUMBING CHECK: Slowly turn on the water supply to the machine after the incoming fill line and the drain line have been installed. Check for any leaks and repair as required. All leaks must be repaired prior to placing the machine in opera- tion.

ELECTRICAL POWER CONNECTION: Electrical and grounding connections must comply with the applicable por- tions of the National Electrical Code ANSI/NFPA 70 (latest edi- tion) and/or other electrical codes. Disconnect electrical power supply and place a tag at the disconnect switch to indi- cate that you are working on the circuit.

The dishmachine data plate is located on the right side of the door. Refer to the data plate for machine operating require- ments, machine voltage, total amperage load and serial num- ber.

To install the incoming power lines, remove the electrical box cover. This will require taking a phillipshead screwdriver and removing the two (2) screws at the bottom corners and lift up and off. Let the cover rest against the plumbing assembly. Install conduit from the underside of machine to hole in rear of electrical box below terminal block and ground lug. Install the service wires (L1 & L2) to the appropriate terminals as they

VOLTAGE CHECK: Ensure that the power switch is in the OFF position and apply power to the dishmachine. Check the incoming power at the terminal block and ensure it corre- sponds to the voltage listed on the data plate. If not, contact a qualified service agency to examine the problem. Do not run the dishmachine if the voltage is too high or too low. Shut off the service breaker and mark it as being for the dishmachine. Advise all proper personnel of any problems and of the loca- tion of the service breaker. Replace the electrical box cover and tighten down the screws.

Delta 1200 Technical Manual

Issued:

6