IMPORTANT: The conveyor belt has been over- tensioned for shipping purposes. It must be re- tensioned before operating the sander! See “Conveyor Belt Tension/Tracking” on page 16.

Infeed/Outfeed Tables (Optional

Accessory)

The sander should be bolted to the stand or a work table when using these table extensions. Maximum working load of a table is 35 pounds.

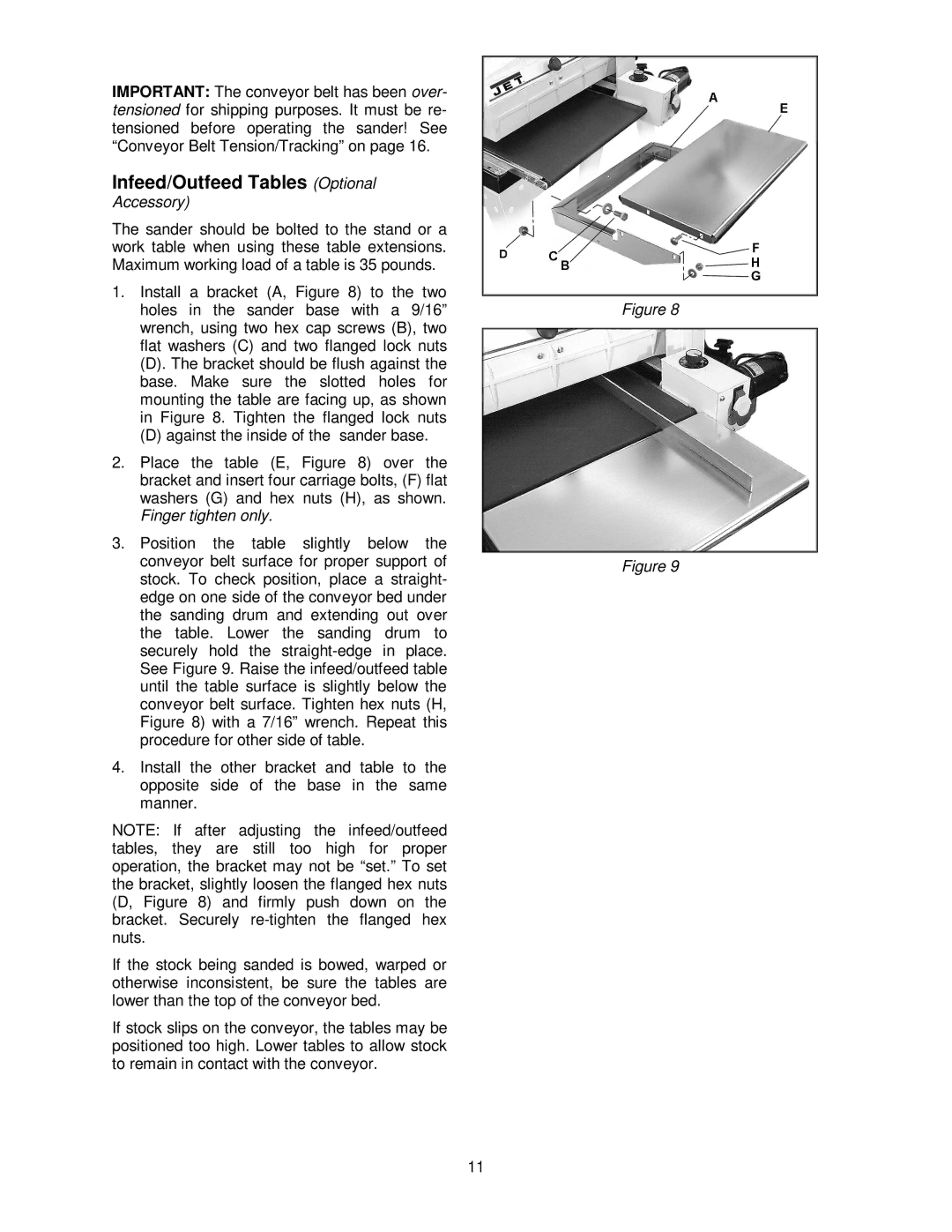

1.Install a bracket (A, Figure 8) to the two holes in the sander base with a 9/16” wrench, using two hex cap screws (B), two flat washers (C) and two flanged lock nuts

(D).The bracket should be flush against the base. Make sure the slotted holes for mounting the table are facing up, as shown in Figure 8. Tighten the flanged lock nuts

(D)against the inside of the sander base.

2.Place the table (E, Figure 8) over the bracket and insert four carriage bolts, (F) flat washers (G) and hex nuts (H), as shown. Finger tighten only.

3.Position the table slightly below the conveyor belt surface for proper support of stock. To check position, place a straight- edge on one side of the conveyor bed under the sanding drum and extending out over the table. Lower the sanding drum to securely hold the

4.Install the other bracket and table to the opposite side of the base in the same manner.

NOTE: If after adjusting the infeed/outfeed tables, they are still too high for proper operation, the bracket may not be “set.” To set the bracket, slightly loosen the flanged hex nuts (D, Figure 8) and firmly push down on the bracket. Securely

If the stock being sanded is bowed, warped or otherwise inconsistent, be sure the tables are lower than the top of the conveyor bed.

If stock slips on the conveyor, the tables may be positioned too high. Lower tables to allow stock to remain in contact with the conveyor.

11

Figure 8

Figure 9