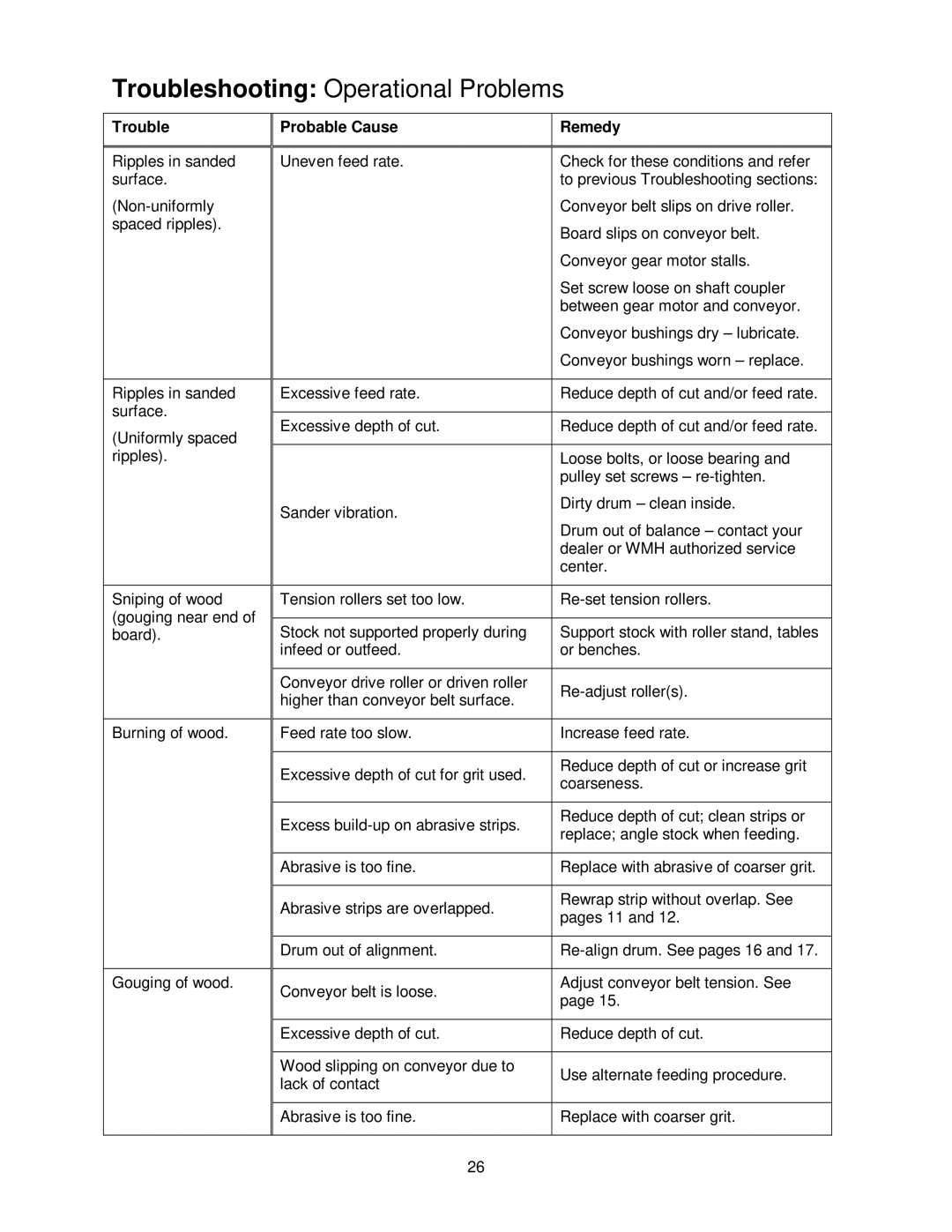

Troubleshooting: Operational Problems

Trouble

Ripples in sanded surface.

Ripples in sanded surface.

(Uniformly spaced ripples).

Sniping of wood (gouging near end of board).

Burning of wood.

Gouging of wood.

Probable Cause | Remedy | |

|

| |

Uneven feed rate. | Check for these conditions and refer | |

| to previous Troubleshooting sections: | |

| Conveyor belt slips on drive roller. | |

| Board slips on conveyor belt. | |

| Conveyor gear motor stalls. | |

| Set screw loose on shaft coupler | |

| between gear motor and conveyor. | |

| Conveyor bushings dry – lubricate. | |

| Conveyor bushings worn – replace. | |

|

| |

Excessive feed rate. | Reduce depth of cut and/or feed rate. | |

|

| |

Excessive depth of cut. | Reduce depth of cut and/or feed rate. | |

|

| |

| Loose bolts, or loose bearing and | |

| pulley set screws – | |

Sander vibration. | Dirty drum – clean inside. | |

Drum out of balance – contact your | ||

| ||

| dealer or WMH authorized service | |

| center. | |

|

| |

Tension rollers set too low. | ||

|

| |

Stock not supported properly during | Support stock with roller stand, tables | |

infeed or outfeed. | or benches. | |

|

| |

Conveyor drive roller or driven roller | ||

higher than conveyor belt surface. | ||

| ||

|

| |

Feed rate too slow. | Increase feed rate. | |

|

| |

Excessive depth of cut for grit used. | Reduce depth of cut or increase grit | |

coarseness. | ||

| ||

|

| |

Excess | Reduce depth of cut; clean strips or | |

replace; angle stock when feeding. | ||

| ||

|

| |

Abrasive is too fine. | Replace with abrasive of coarser grit. | |

|

| |

Abrasive strips are overlapped. | Rewrap strip without overlap. See | |

pages 11 and 12. | ||

| ||

|

| |

Drum out of alignment. | ||

|

| |

Conveyor belt is loose. | Adjust conveyor belt tension. See | |

page 15. | ||

| ||

|

| |

Excessive depth of cut. | Reduce depth of cut. | |

|

| |

Wood slipping on conveyor due to | Use alternate feeding procedure. | |

lack of contact | ||

| ||

|

| |

Abrasive is too fine. | Replace with coarser grit. | |

|

|

26