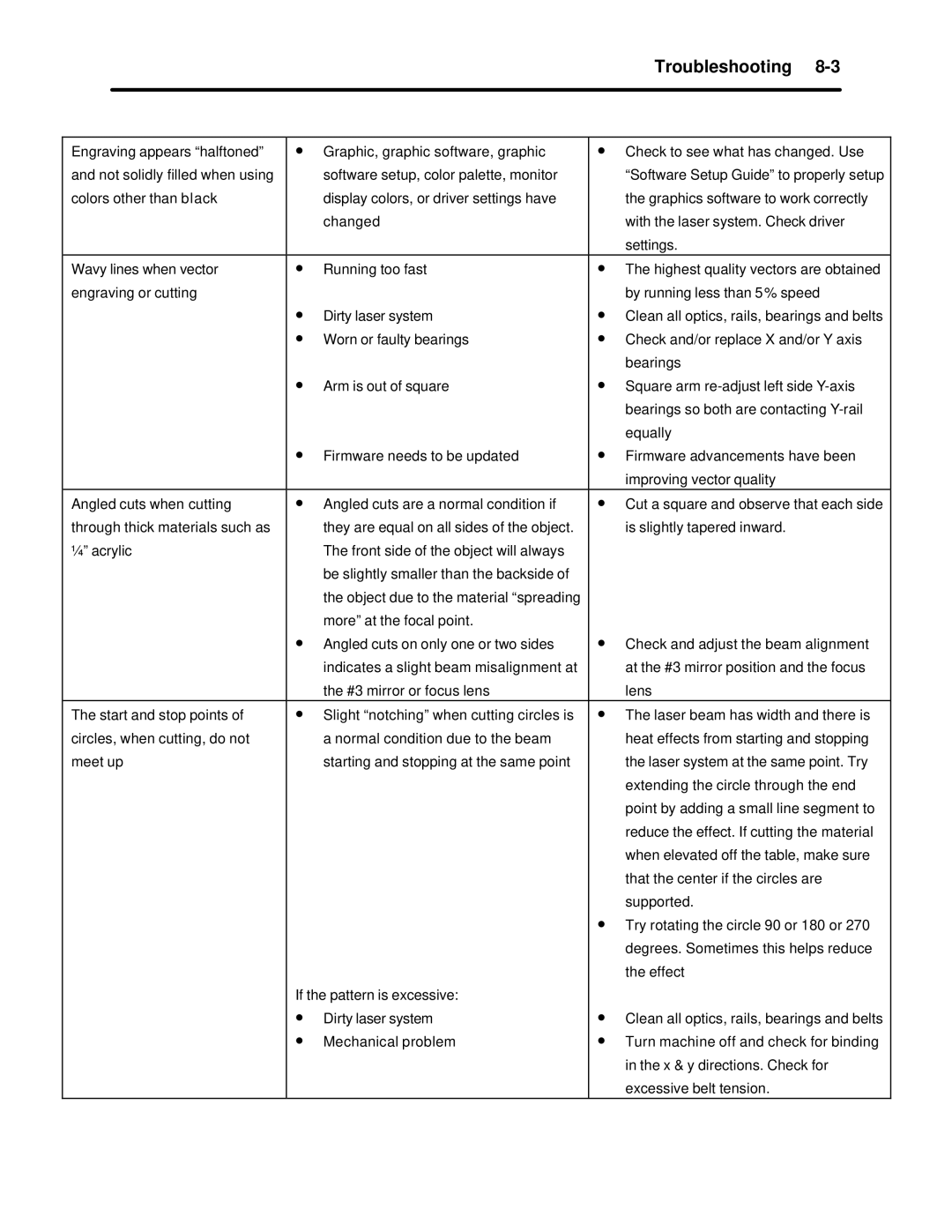

Troubleshooting 8-3

Engraving appears “halftoned” | ∙ | Graphic, graphic software, graphic | ∙ Check to see what has changed. Use |

and not solidly filled when using |

| software setup, color palette, monitor | “Software Setup Guide” to properly setup |

colors other than black |

| display colors, or driver settings have | the graphics software to work correctly |

|

| changed | with the laser system. Check driver |

|

|

| settings. |

Wavy lines when vector | ∙ | Running too fast | ∙ The highest quality vectors are obtained |

engraving or cutting |

|

| by running less than 5% speed |

| ∙ | Dirty laser system | ∙ Clean all optics, rails, bearings and belts |

| ∙ Worn or faulty bearings | ∙ Check and/or replace X and/or Y axis | |

|

|

| bearings |

| ∙ Arm is out of square | ∙ Square arm | |

|

|

| bearings so both are contacting |

|

|

| equally |

| ∙ Firmware needs to be updated | ∙ Firmware advancements have been | |

|

|

| improving vector quality |

Angled cuts when cutting | ∙ | Angled cuts are a normal condition if | ∙ Cut a square and observe that each side |

through thick materials such as |

| they are equal on all sides of the object. | is slightly tapered inward. |

¼” acrylic |

| The front side of the object will always |

|

|

| be slightly smaller than the backside of |

|

|

| the object due to the material “spreading |

|

|

| more” at the focal point. |

|

| ∙ Angled cuts on only one or two sides | ∙ Check and adjust the beam alignment | |

|

| indicates a slight beam misalignment at | at the #3 mirror position and the focus |

|

| the #3 mirror or focus lens | lens |

The start and stop points of | ∙ | Slight “notching” when cutting circles is | ∙ The laser beam has width and there is |

circles, when cutting, do not |

| a normal condition due to the beam | heat effects from starting and stopping |

meet up |

| starting and stopping at the same point | the laser system at the same point. Try |

|

|

| extending the circle through the end |

|

|

| point by adding a small line segment to |

|

|

| reduce the effect. If cutting the material |

|

|

| when elevated off the table, make sure |

|

|

| that the center if the circles are |

|

|

| supported. |

|

|

| ∙ Try rotating the circle 90 or 180 or 270 |

|

|

| degrees. Sometimes this helps reduce |

|

|

| the effect |

| If the pattern is excessive: |

| |

| ∙ | Dirty laser system | ∙ Clean all optics, rails, bearings and belts |

| ∙ | Mechanical problem | ∙ Turn machine off and check for binding |

|

|

| in the x & y directions. Check for |

|

|

| excessive belt tension. |