7-8 Maintenance

Cooling Fan Filters

This |

|

|

|

|

|

|

|

|

|

| |

require periodic cleaning of the |

|

|

|

|

|

cooling fan filters. Since ambient |

|

|

|

|

|

|

|

|

|

| |

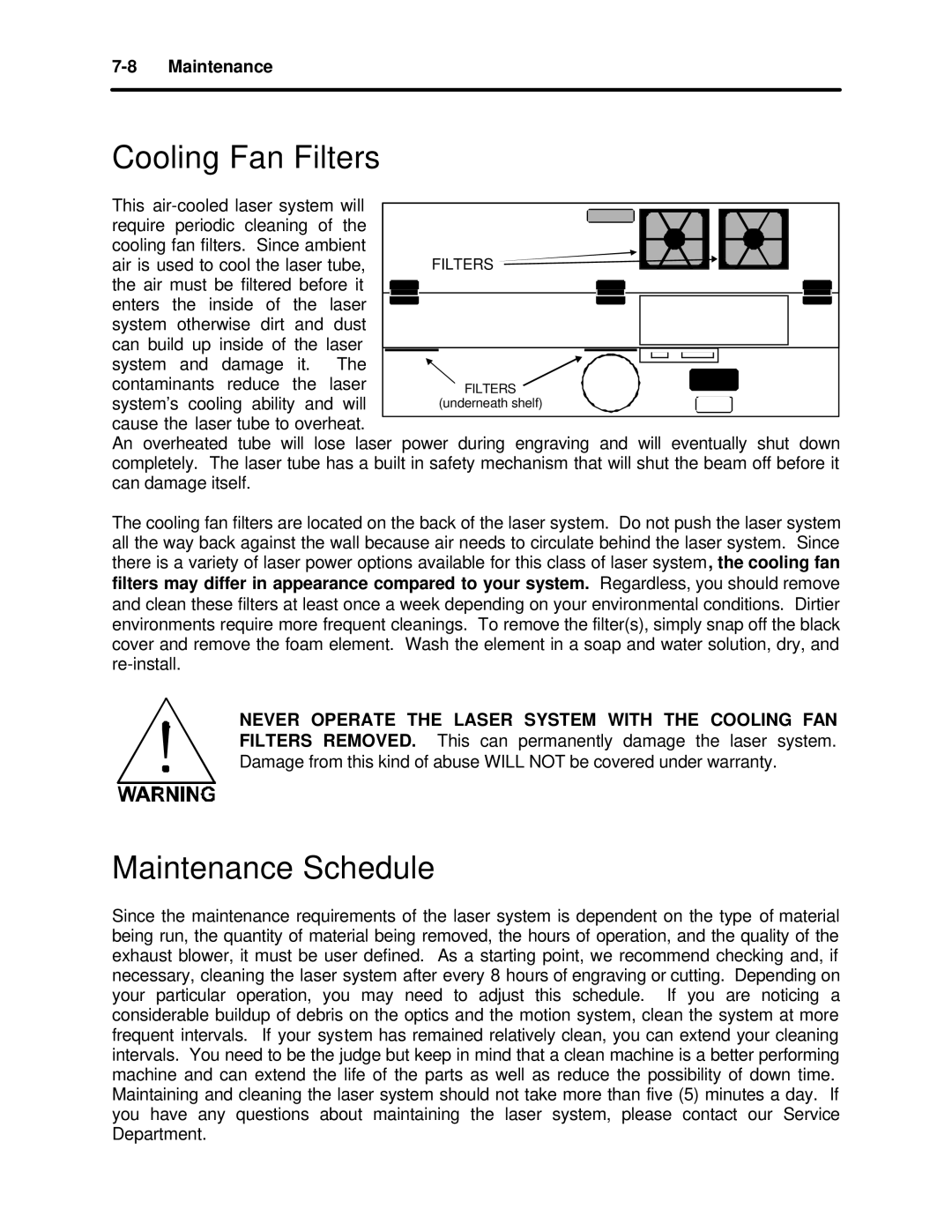

air is used to cool the laser tube, | FILTERS | ||||

the air must be filtered before it |

|

|

|

|

|

enters the inside of the laser |

|

|

|

|

|

system otherwise dirt and dust |

|

|

|

|

|

can build up inside of the laser |

|

|

|

|

|

|

|

|

|

| |

system and damage it. The |

|

|

|

|

|

contaminants reduce the laser | FILTERS | ||||

system’s cooling ability and will | (underneath shelf) | ||||

cause the laser tube to overheat. |

|

|

|

|

|

|

|

|

|

| |

An overheated tube will lose laser power during engraving and will eventually shut down completely. The laser tube has a built in safety mechanism that will shut the beam off before it can damage itself.

The cooling fan filters are located on the back of the laser system. Do not push the laser system all the way back against the wall because air needs to circulate behind the laser system. Since there is a variety of laser power options available for this class of laser system, the cooling fan filters may differ in appearance compared to your system. Regardless, you should remove and clean these filters at least once a week depending on your environmental conditions. Dirtier environments require more frequent cleanings. To remove the filter(s), simply snap off the black cover and remove the foam element. Wash the element in a soap and water solution, dry, and

NEVER OPERATE THE LASER SYSTEM WITH THE COOLING FAN FILTERS REMOVED. This can permanently damage the laser system. Damage from this kind of abuse WILL NOT be covered under warranty.

Maintenance Schedule

Since the maintenance requirements of the laser system is dependent on the type of material being run, the quantity of material being removed, the hours of operation, and the quality of the exhaust blower, it must be user defined. As a starting point, we recommend checking and, if necessary, cleaning the laser system after every 8 hours of engraving or cutting. Depending on your particular operation, you may need to adjust this schedule. If you are noticing a considerable buildup of debris on the optics and the motion system, clean the system at more frequent intervals. If your system has remained relatively clean, you can extend your cleaning intervals. You need to be the judge but keep in mind that a clean machine is a better performing machine and can extend the life of the parts as well as reduce the possibility of down time. Maintaining and cleaning the laser system should not take more than five (5) minutes a day. If you have any questions about maintaining the laser system, please contact our Service Department.