6-22 Sample Materials

WOOD

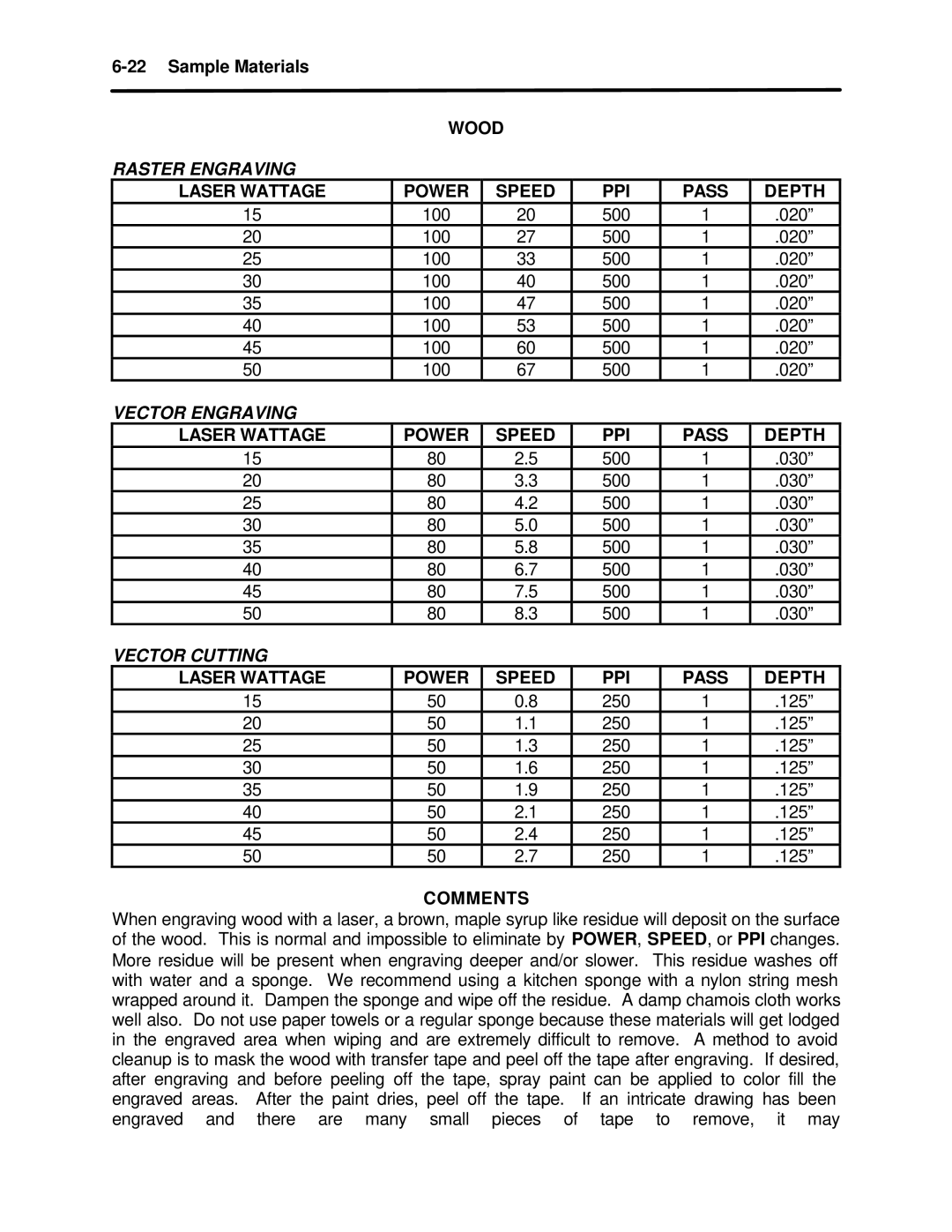

RASTER ENGRAVING

LASER WATTAGE | POWER | SPEED | PPI | PASS | DEPTH |

15 | 100 | 20 | 500 | 1 | .020” |

20 | 100 | 27 | 500 | 1 | .020” |

25 | 100 | 33 | 500 | 1 | .020” |

30 | 100 | 40 | 500 | 1 | .020” |

35 | 100 | 47 | 500 | 1 | .020” |

40 | 100 | 53 | 500 | 1 | .020” |

45 | 100 | 60 | 500 | 1 | .020” |

50 | 100 | 67 | 500 | 1 | .020” |

VECTOR ENGRAVING |

|

|

|

|

|

LASER WATTAGE | POWER | SPEED | PPI | PASS | DEPTH |

15 | 80 | 2.5 | 500 | 1 | .030” |

20 | 80 | 3.3 | 500 | 1 | .030” |

25 | 80 | 4.2 | 500 | 1 | .030” |

30 | 80 | 5.0 | 500 | 1 | .030” |

35 | 80 | 5.8 | 500 | 1 | .030” |

40 | 80 | 6.7 | 500 | 1 | .030” |

45 | 80 | 7.5 | 500 | 1 | .030” |

50 | 80 | 8.3 | 500 | 1 | .030” |

VECTOR CUTTING |

|

|

|

|

|

LASER WATTAGE | POWER | SPEED | PPI | PASS | DEPTH |

15 | 50 | 0.8 | 250 | 1 | .125” |

20 | 50 | 1.1 | 250 | 1 | .125” |

25 | 50 | 1.3 | 250 | 1 | .125” |

30 | 50 | 1.6 | 250 | 1 | .125” |

35 | 50 | 1.9 | 250 | 1 | .125” |

40 | 50 | 2.1 | 250 | 1 | .125” |

45 | 50 | 2.4 | 250 | 1 | .125” |

50 | 50 | 2.7 | 250 | 1 | .125” |

COMMENTS

When engraving wood with a laser, a brown, maple syrup like residue will deposit on the surface of the wood. This is normal and impossible to eliminate by POWER, SPEED, or PPI changes. More residue will be present when engraving deeper and/or slower. This residue washes off with water and a sponge. We recommend using a kitchen sponge with a nylon string mesh wrapped around it. Dampen the sponge and wipe off the residue. A damp chamois cloth works well also. Do not use paper towels or a regular sponge because these materials will get lodged in the engraved area when wiping and are extremely difficult to remove. A method to avoid cleanup is to mask the wood with transfer tape and peel off the tape after engraving. If desired, after engraving and before peeling off the tape, spray paint can be applied to color fill the engraved areas. After the paint dries, peel off the tape. If an intricate drawing has been engraved and there are many small pieces of tape to remove, it may