6-20 Sample Materials

RUBBER STAMPS

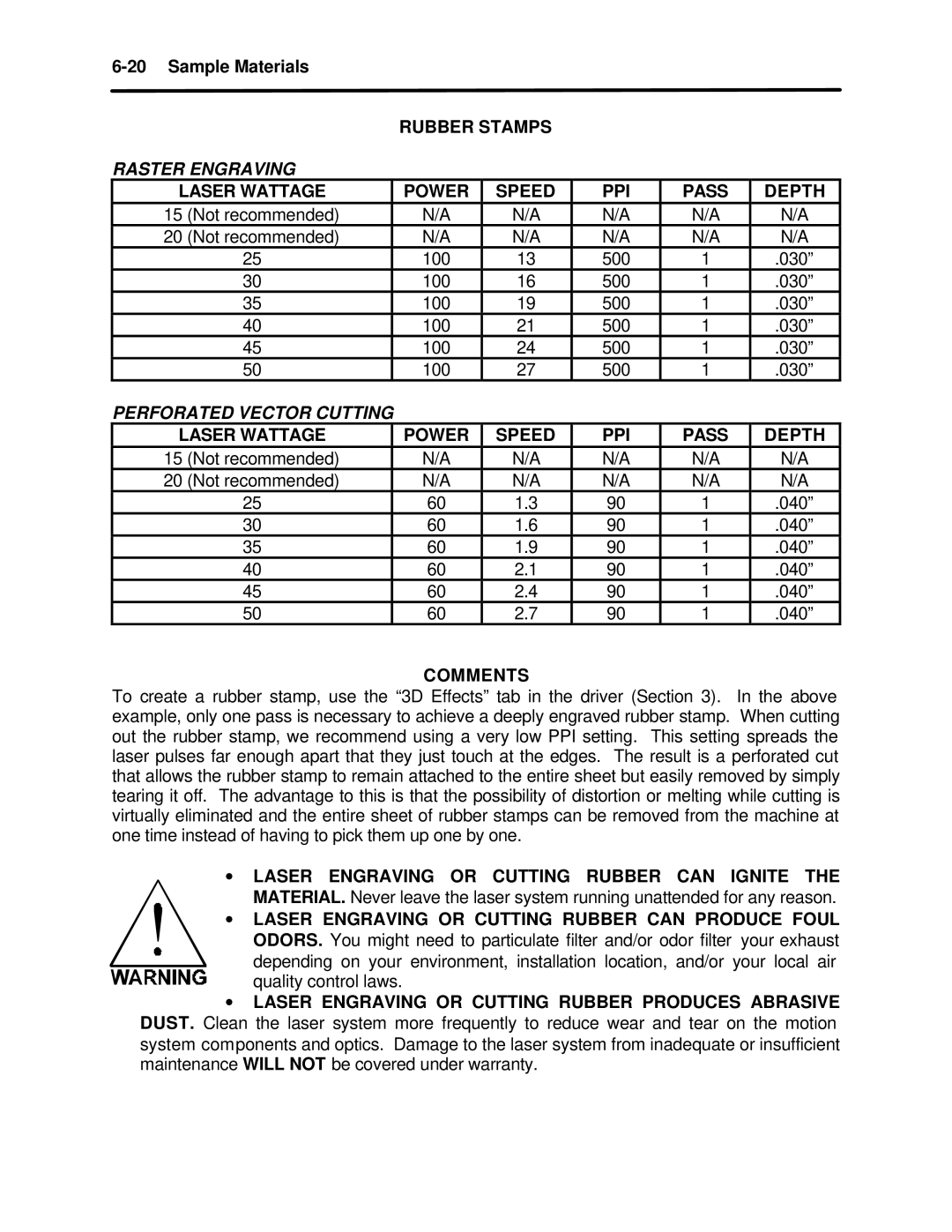

RASTER ENGRAVING

LASER WATTAGE | POWER | SPEED | PPI | PASS | DEPTH |

15 (Not recommended) | N/A | N/A | N/A | N/A | N/A |

20 (Not recommended) | N/A | N/A | N/A | N/A | N/A |

25 | 100 | 13 | 500 | 1 | .030” |

30 | 100 | 16 | 500 | 1 | .030” |

35 | 100 | 19 | 500 | 1 | .030” |

40 | 100 | 21 | 500 | 1 | .030” |

45 | 100 | 24 | 500 | 1 | .030” |

50 | 100 | 27 | 500 | 1 | .030” |

PERFORATED VECTOR CUTTING |

|

|

|

|

|

LASER WATTAGE | POWER | SPEED | PPI | PASS | DEPTH |

15 (Not recommended) | N/A | N/A | N/A | N/A | N/A |

20 (Not recommended) | N/A | N/A | N/A | N/A | N/A |

25 | 60 | 1.3 | 90 | 1 | .040” |

30 | 60 | 1.6 | 90 | 1 | .040” |

35 | 60 | 1.9 | 90 | 1 | .040” |

40 | 60 | 2.1 | 90 | 1 | .040” |

45 | 60 | 2.4 | 90 | 1 | .040” |

50 | 60 | 2.7 | 90 | 1 | .040” |

COMMENTS

To create a rubber stamp, use the “3D Effects” tab in the driver (Section 3). In the above example, only one pass is necessary to achieve a deeply engraved rubber stamp. When cutting out the rubber stamp, we recommend using a very low PPI setting. This setting spreads the laser pulses far enough apart that they just touch at the edges. The result is a perforated cut that allows the rubber stamp to remain attached to the entire sheet but easily removed by simply tearing it off. The advantage to this is that the possibility of distortion or melting while cutting is virtually eliminated and the entire sheet of rubber stamps can be removed from the machine at one time instead of having to pick them up one by one.

∙LASER ENGRAVING OR CUTTING RUBBER CAN IGNITE THE MATERIAL. Never leave the laser system running unattended for any reason.

∙LASER ENGRAVING OR CUTTING RUBBER CAN PRODUCE FOUL ODORS. You might need to particulate filter and/or odor filter your exhaust

depending on your environment, installation location, and/or your local air quality control laws.

∙LASER ENGRAVING OR CUTTING RUBBER PRODUCES ABRASIVE DUST. Clean the laser system more frequently to reduce wear and tear on the motion system components and optics. Damage to the laser system from inadequate or insufficient maintenance WILL NOT be covered under warranty.