Uncrating and Cleanup

1.Read and understand the entire manual before attempting setup or operation.

2.Finish uncrating the saw and inspect for damage. If any damage has occurred, contact your local distributor.

3.Remove all bolts attaching machine to shipping base.

4.Leave packing material between vice clamps and saw head intact until bandsaw has been lifted to its final position.

5.Clean all rust protected surfaces with kerosene or diesel oil to remove protective coating. Do not use gasoline, paint thinner, mineral spirits, etc. These may damage painted surfaces.

6.Lubricate all slideways with a light film of Mobil DTE Oil Heavy Medium.

Installation

For best performance, the bandsaw should be located on a solid and level foundation. Allow room for servicing and for moving large stock around the bandsaw when deciding a location for the machine.

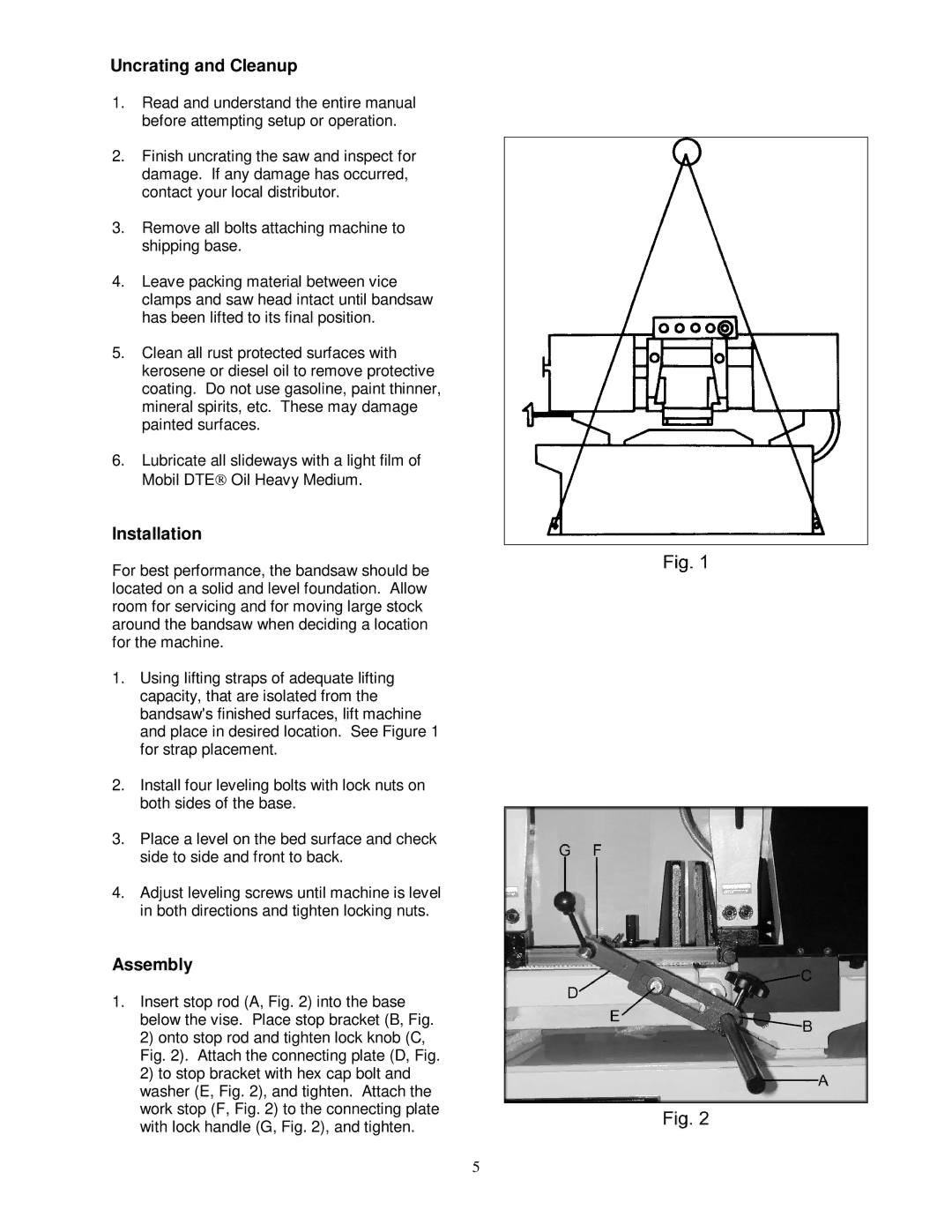

1.Using lifting straps of adequate lifting capacity, that are isolated from the bandsaw's finished surfaces, lift machine and place in desired location. See Figure 1 for strap placement.

2.Install four leveling bolts with lock nuts on both sides of the base.

3.Place a level on the bed surface and check side to side and front to back.

4.Adjust leveling screws until machine is level in both directions and tighten locking nuts.

Assembly

1.Insert stop rod (A, Fig. 2) into the base below the vise. Place stop bracket (B, Fig.

2)onto stop rod and tighten lock knob (C, Fig. 2). Attach the connecting plate (D, Fig.

2)to stop bracket with hex cap bolt and washer (E, Fig. 2), and tighten. Attach the work stop (F, Fig. 2) to the connecting plate with lock handle (G, Fig. 2), and tighten.

5