Changing Blade Speed

1.Disconnect the machine from the power source.

2.Place saw arm in the horizontal position.

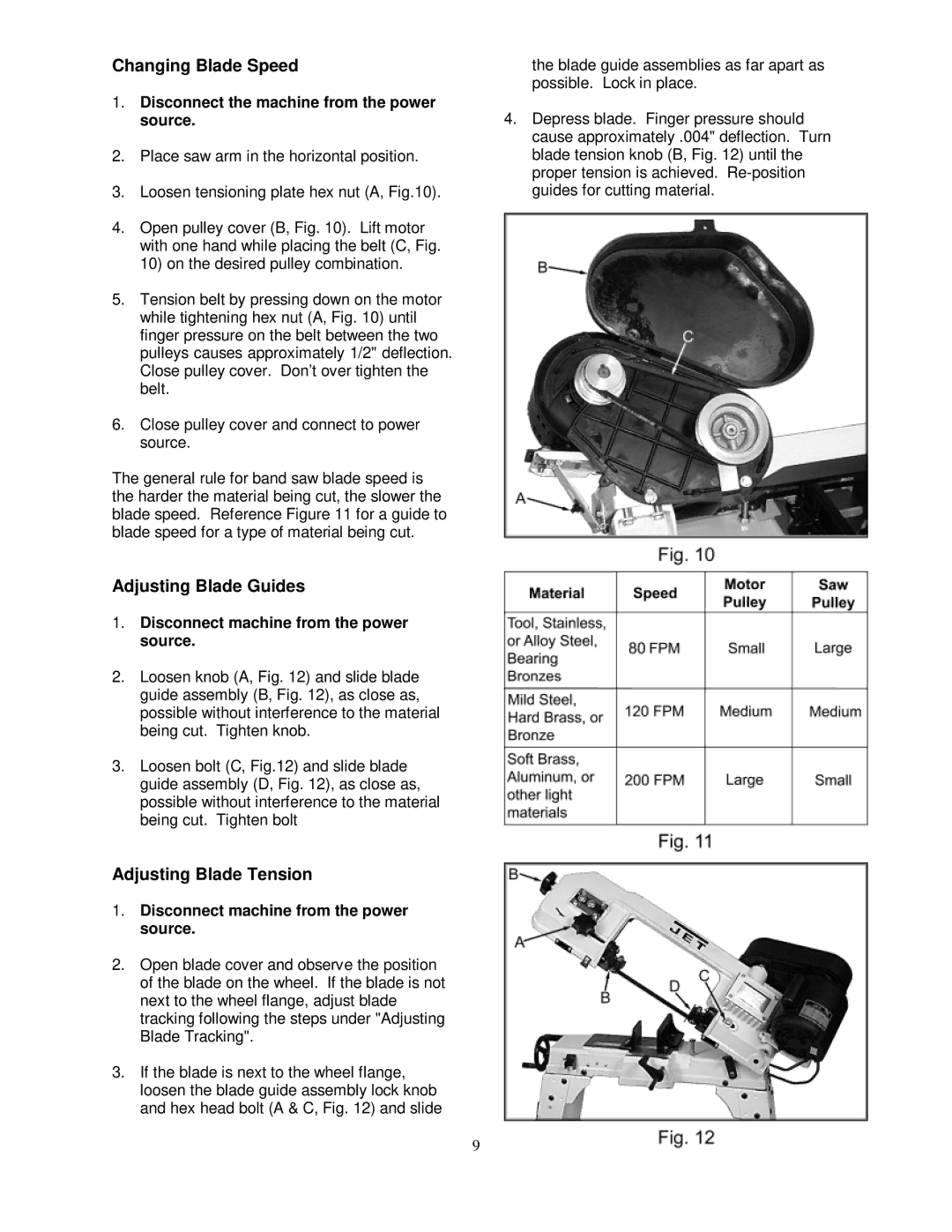

3.Loosen tensioning plate hex nut (A, Fig.10).

4.Open pulley cover (B, Fig. 10). Lift motor with one hand while placing the belt (C, Fig. 10) on the desired pulley combination.

5.Tension belt by pressing down on the motor while tightening hex nut (A, Fig. 10) until finger pressure on the belt between the two pulleys causes approximately 1/2" deflection. Close pulley cover. Don’t over tighten the belt.

6.Close pulley cover and connect to power source.

The general rule for band saw blade speed is the harder the material being cut, the slower the blade speed. Reference Figure 11 for a guide to blade speed for a type of material being cut.

Adjusting Blade Guides

1.Disconnect machine from the power source.

2.Loosen knob (A, Fig. 12) and slide blade guide assembly (B, Fig. 12), as close as, possible without interference to the material being cut. Tighten knob.

3.Loosen bolt (C, Fig.12) and slide blade guide assembly (D, Fig. 12), as close as, possible without interference to the material being cut. Tighten bolt

Adjusting Blade Tension

1.Disconnect machine from the power source.

2.Open blade cover and observe the position of the blade on the wheel. If the blade is not next to the wheel flange, adjust blade tracking following the steps under "Adjusting Blade Tracking".

3.If the blade is next to the wheel flange, loosen the blade guide assembly lock knob and hex head bolt (A & C, Fig. 12) and slide

the blade guide assemblies as far apart as possible. Lock in place.

4.Depress blade. Finger pressure should cause approximately .004" deflection. Turn blade tension knob (B, Fig. 12) until the proper tension is achieved.

9