8.Position second guide rail on the table. Placement of this rail depends on the width of the board and if the board requires outer edge

9.Clamp or nail second guide rail.

10.Replace dust hood, dust chute and fasten in place.

11.Connect to the dust collection system.

12.Make sure all adjusting tools and wood stock are removed from the machine.

TIP: Save money, time, and frustration by experimenting first with scrap work pieces before attempting to mold with expensive stock.

13.0Molding procedure

![]() Never mold without using a dust collector. Molding without a dust collector may cause clogging of and damage to machine.

Never mold without using a dust collector. Molding without a dust collector may cause clogging of and damage to machine.

Molding with professional results takes planning prior to starting. Always take a light cut for the smoother finish.

With profiles that require outer edge

Figure 21

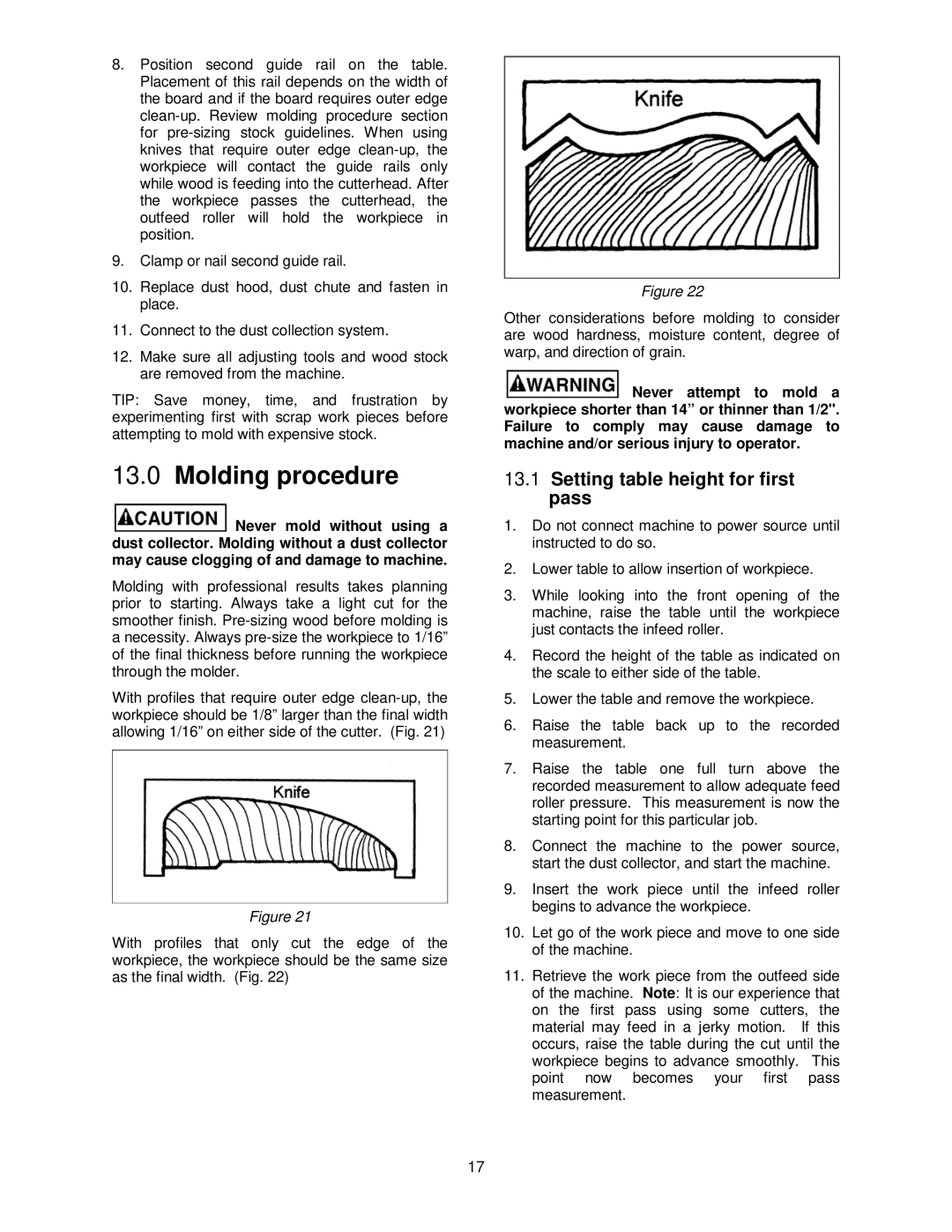

With profiles that only cut the edge of the workpiece, the workpiece should be the same size as the final width. (Fig. 22)

Figure 22

Other considerations before molding to consider are wood hardness, moisture content, degree of warp, and direction of grain.

![]() Never attempt to mold a workpiece shorter than 14” or thinner than 1/2". Failure to comply may cause damage to machine and/or serious injury to operator.

Never attempt to mold a workpiece shorter than 14” or thinner than 1/2". Failure to comply may cause damage to machine and/or serious injury to operator.

13.1Setting table height for first pass

1.Do not connect machine to power source until instructed to do so.

2.Lower table to allow insertion of workpiece.

3.While looking into the front opening of the machine, raise the table until the workpiece just contacts the infeed roller.

4.Record the height of the table as indicated on the scale to either side of the table.

5.Lower the table and remove the workpiece.

6.Raise the table back up to the recorded measurement.

7.Raise the table one full turn above the recorded measurement to allow adequate feed roller pressure. This measurement is now the starting point for this particular job.

8.Connect the machine to the power source, start the dust collector, and start the machine.

9.Insert the work piece until the infeed roller begins to advance the workpiece.

10.Let go of the work piece and move to one side of the machine.

11.Retrieve the work piece from the outfeed side of the machine. Note: It is our experience that on the first pass using some cutters, the material may feed in a jerky motion. If this occurs, raise the table during the cut until the workpiece begins to advance smoothly. This point now becomes your first pass measurement.

17