12.3Making & installing a bedboard

![]() You must use a board over the planer/molder table when molding. This prevents the knives from hitting the table and allows the knives to cut into the guide boards to clean up the sides of the molding.

You must use a board over the planer/molder table when molding. This prevents the knives from hitting the table and allows the knives to cut into the guide boards to clean up the sides of the molding.

1.Disconnect machine from power source (unplug).

2.Cut a piece of 3/4” particle board

3.Mark and drill four 1/4” holes on the bedboard that match the

4.Countersink the four drilled holes on the top side to allow installation of countersunk screws.

5.Secure the bedboard to the table with four 3/16” x

12.4Making guide rails

Guide rails are used during the molding process to align the workpiece with the molding cutters. Using properly adjusted guide rails assures the workpiece passes the molding cutters in the same position using multiple passes.

Guide rails should be the same length as the table

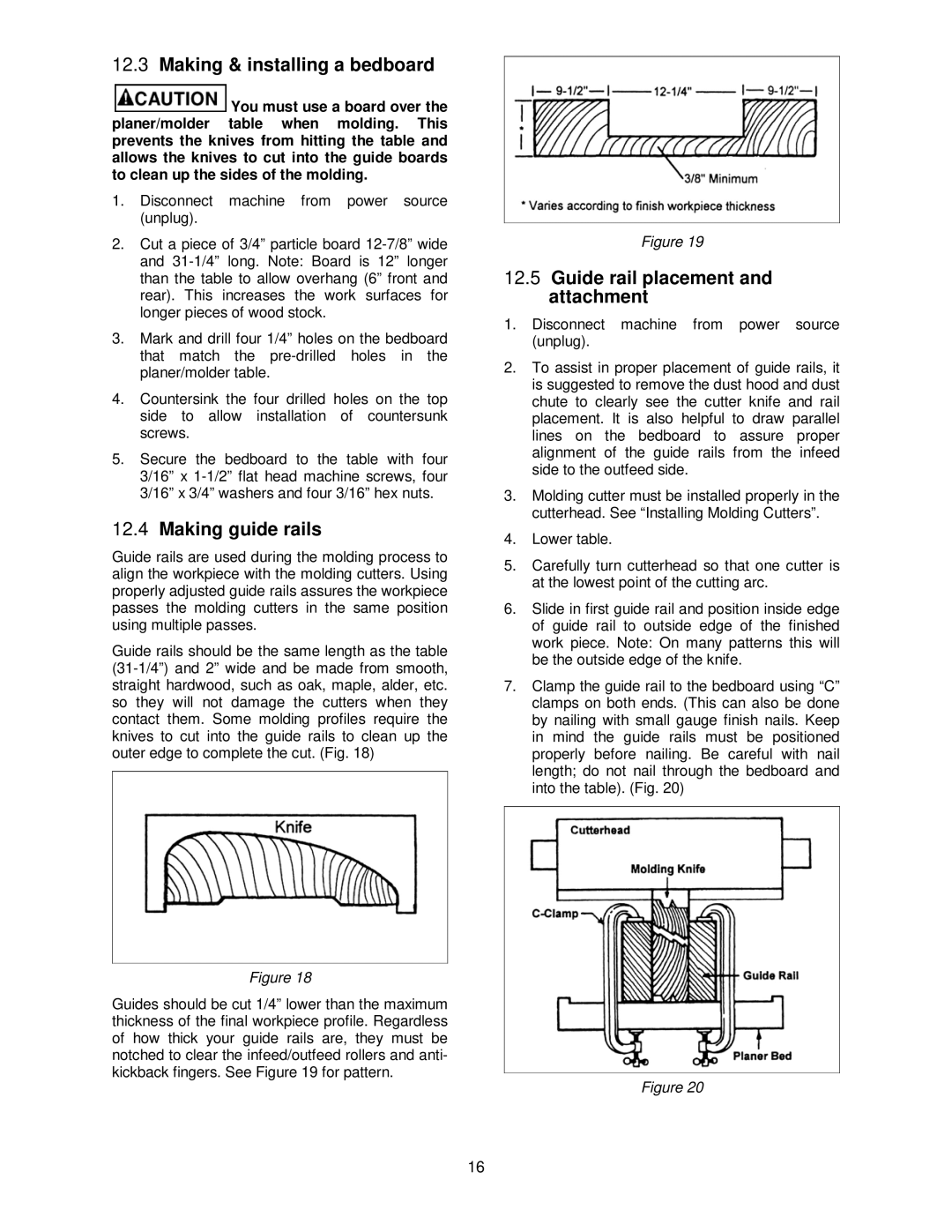

Figure 19

12.5Guide rail placement and attachment

1.Disconnect machine from power source (unplug).

2.To assist in proper placement of guide rails, it is suggested to remove the dust hood and dust chute to clearly see the cutter knife and rail placement. It is also helpful to draw parallel lines on the bedboard to assure proper alignment of the guide rails from the infeed side to the outfeed side.

3.Molding cutter must be installed properly in the cutterhead. See “Installing Molding Cutters”.

4.Lower table.

5.Carefully turn cutterhead so that one cutter is at the lowest point of the cutting arc.

6.Slide in first guide rail and position inside edge of guide rail to outside edge of the finished work piece. Note: On many patterns this will be the outside edge of the knife.

7.Clamp the guide rail to the bedboard using “C” clamps on both ends. (This can also be done by nailing with small gauge finish nails. Keep in mind the guide rails must be positioned properly before nailing. Be careful with nail length; do not nail through the bedboard and into the table). (Fig. 20)

Figure 18

Guides should be cut 1/4” lower than the maximum thickness of the final workpiece profile. Regardless of how thick your guide rails are, they must be notched to clear the infeed/outfeed rollers and anti- kickback fingers. See Figure 19 for pattern.

Figure 20

16