immediately. Do not operate the machine!

Dispose of the packing in an environmentally friendly manner.

Clean all rust protected surfaces with a mild solvent.

Requirements for machine assembly:

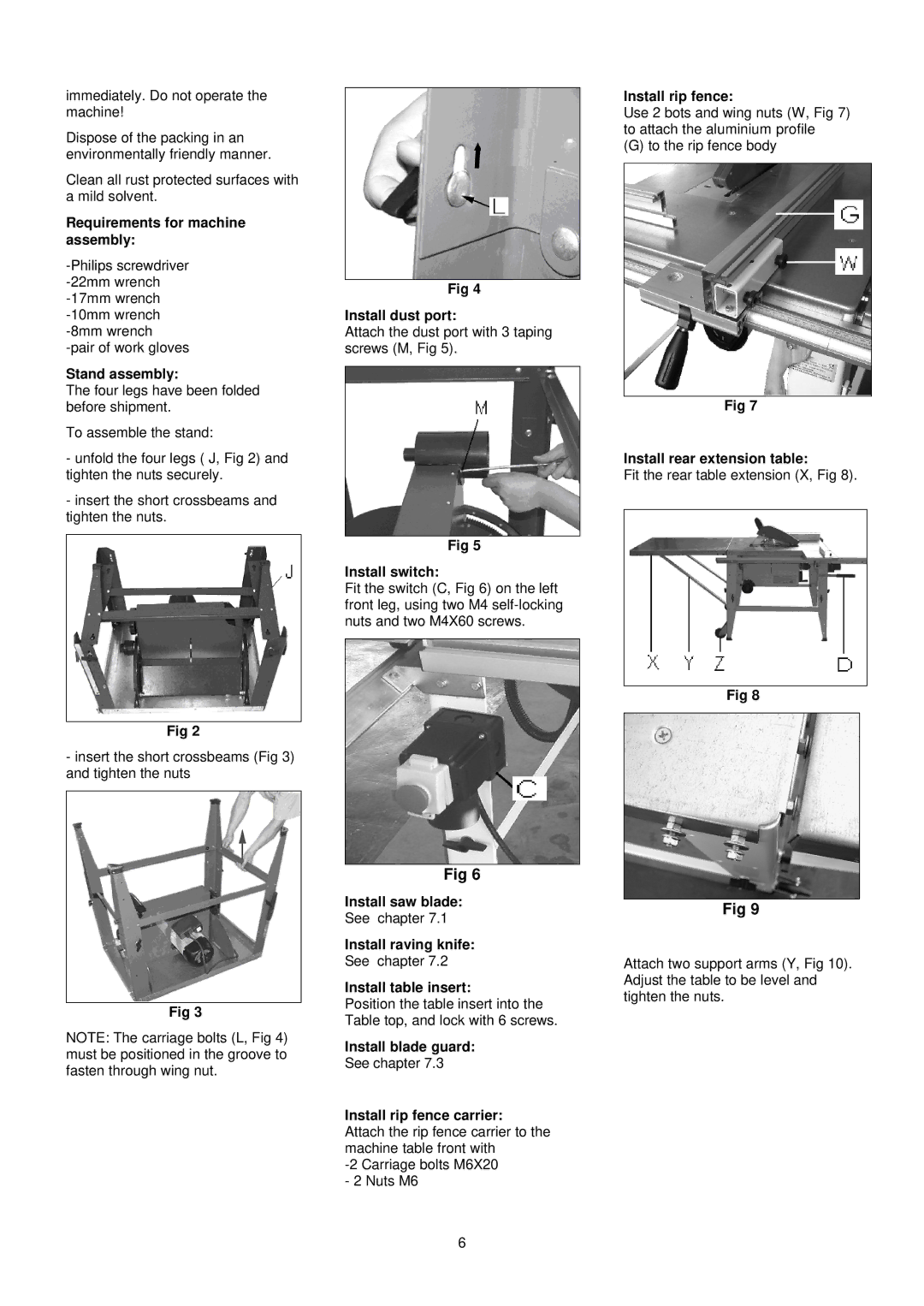

Stand assembly:

The four legs have been folded before shipment.

To assemble the stand:

-unfold the four legs ( J, Fig 2) and tighten the nuts securely.

-insert the short crossbeams and tighten the nuts.

Fig 2

-insert the short crossbeams (Fig 3) and tighten the nuts

Fig 4

Install dust port:

Attach the dust port with 3 taping screws (M, Fig 5).

Fig 5

Install switch:

Fit the switch (C, Fig 6) on the left front leg, using two M4

Install rip fence:

Use 2 bots and wing nuts (W, Fig 7) to attach the aluminium profile

(G) to the rip fence body

Fig 7

Install rear extension table:

Fit the rear table extension (X, Fig 8).

Fig 8

Fig 3

NOTE: The carriage bolts (L, Fig 4) must be positioned in the groove to fasten through wing nut.

Fig 6

Install saw blade:

See chapter 7.1

Install raving knife:

See chapter 7.2

Install table insert:

Position the table insert into the Table top, and lock with 6 screws.

Install blade guard:

See chapter 7.3

Install rip fence carrier:

Attach the rip fence carrier to the machine table front with

6

Fig 9

Attach two support arms (Y, Fig 10). Adjust the table to be level and tighten the nuts.