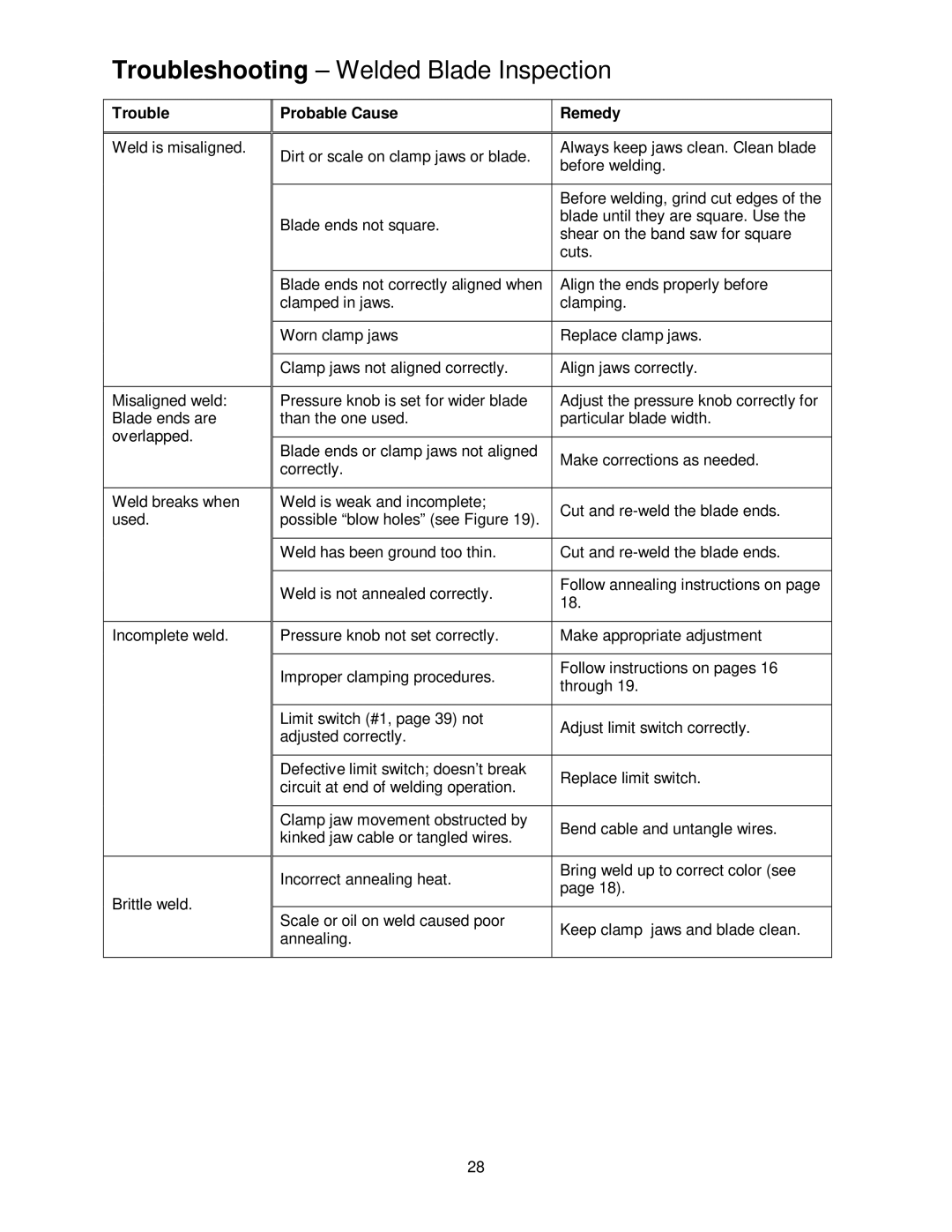

Troubleshooting – Welded Blade Inspection

Trouble

Weld is misaligned.

Misaligned weld: Blade ends are overlapped.

Weld breaks when used.

Incomplete weld.

Brittle weld.

Probable Cause | Remedy | |

|

| |

Dirt or scale on clamp jaws or blade. | Always keep jaws clean. Clean blade | |

before welding. | ||

| ||

|

| |

| Before welding, grind cut edges of the | |

Blade ends not square. | blade until they are square. Use the | |

shear on the band saw for square | ||

| ||

| cuts. | |

|

| |

Blade ends not correctly aligned when | Align the ends properly before | |

clamped in jaws. | clamping. | |

|

| |

Worn clamp jaws | Replace clamp jaws. | |

|

| |

Clamp jaws not aligned correctly. | Align jaws correctly. | |

|

| |

Pressure knob is set for wider blade | Adjust the pressure knob correctly for | |

than the one used. | particular blade width. | |

|

| |

Blade ends or clamp jaws not aligned | Make corrections as needed. | |

correctly. | ||

| ||

|

| |

Weld is weak and incomplete; | Cut and | |

possible “blow holes” (see Figure 19). | ||

| ||

|

| |

Weld has been ground too thin. | Cut and | |

|

| |

Weld is not annealed correctly. | Follow annealing instructions on page | |

18. | ||

| ||

|

| |

Pressure knob not set correctly. | Make appropriate adjustment | |

|

| |

Improper clamping procedures. | Follow instructions on pages 16 | |

through 19. | ||

| ||

|

| |

Limit switch (#1, page 39) not | Adjust limit switch correctly. | |

adjusted correctly. | ||

| ||

|

| |

Defective limit switch; doesn’t break | Replace limit switch. | |

circuit at end of welding operation. | ||

| ||

|

| |

Clamp jaw movement obstructed by | Bend cable and untangle wires. | |

kinked jaw cable or tangled wires. | ||

| ||

|

| |

Incorrect annealing heat. | Bring weld up to correct color (see | |

page 18). | ||

| ||

|

| |

Scale or oil on weld caused poor | Keep clamp jaws and blade clean. | |

annealing. | ||

| ||

|

|

28