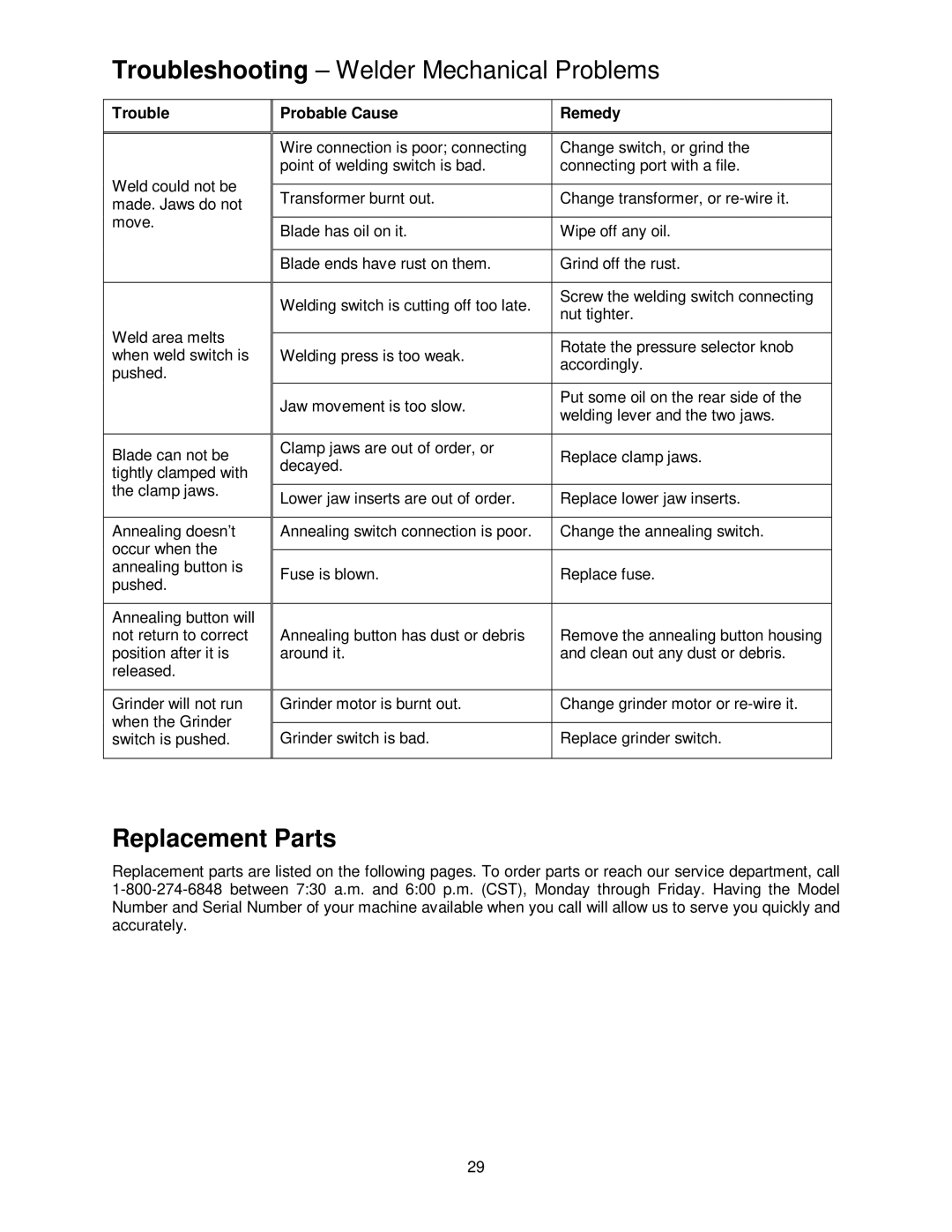

Troubleshooting – Welder Mechanical Problems

Trouble

Weld could not be made. Jaws do not move.

Weld area melts when weld switch is pushed.

Blade can not be tightly clamped with the clamp jaws.

Annealing doesn’t occur when the annealing button is pushed.

Annealing button will not return to correct position after it is released.

Grinder will not run when the Grinder switch is pushed.

Probable Cause | Remedy | |

|

| |

Wire connection is poor; connecting | Change switch, or grind the | |

point of welding switch is bad. | connecting port with a file. | |

|

| |

Transformer burnt out. | Change transformer, or | |

|

| |

Blade has oil on it. | Wipe off any oil. | |

|

| |

Blade ends have rust on them. | Grind off the rust. | |

|

| |

Welding switch is cutting off too late. | Screw the welding switch connecting | |

nut tighter. | ||

| ||

|

| |

Welding press is too weak. | Rotate the pressure selector knob | |

accordingly. | ||

| ||

|

| |

Jaw movement is too slow. | Put some oil on the rear side of the | |

welding lever and the two jaws. | ||

| ||

|

| |

Clamp jaws are out of order, or | Replace clamp jaws. | |

decayed. | ||

| ||

|

| |

Lower jaw inserts are out of order. | Replace lower jaw inserts. | |

|

| |

Annealing switch connection is poor. | Change the annealing switch. | |

|

| |

Fuse is blown. | Replace fuse. | |

|

| |

Annealing button has dust or debris | Remove the annealing button housing | |

around it. | and clean out any dust or debris. | |

|

| |

Grinder motor is burnt out. | Change grinder motor or | |

|

| |

Grinder switch is bad. | Replace grinder switch. | |

|

|

Replacement Parts

Replacement parts are listed on the following pages. To order parts or reach our service department, call

29