MAINTENANCE

Final setting of the idling speed T

Adjust the idling speed with the screw T, if it is necessary to readjust. First turn the idle speed adjusting screw T clockwise until the cutting attachment starts to rotate/ move.

Then turn, counter- clockwise until the cutting attachment stops. A correctly adjusted idle speed setting occurs when the engine runs smoothly in every position. It should also be good margin to the rpm when the cutting attachment starts to rotate/move.

CAUTION! Contact your servicing dealer, if the idle speed setting cannot be adjusted so that the cutting attachment stops. Do not use the machine until it has been properly adjusted or repaired.

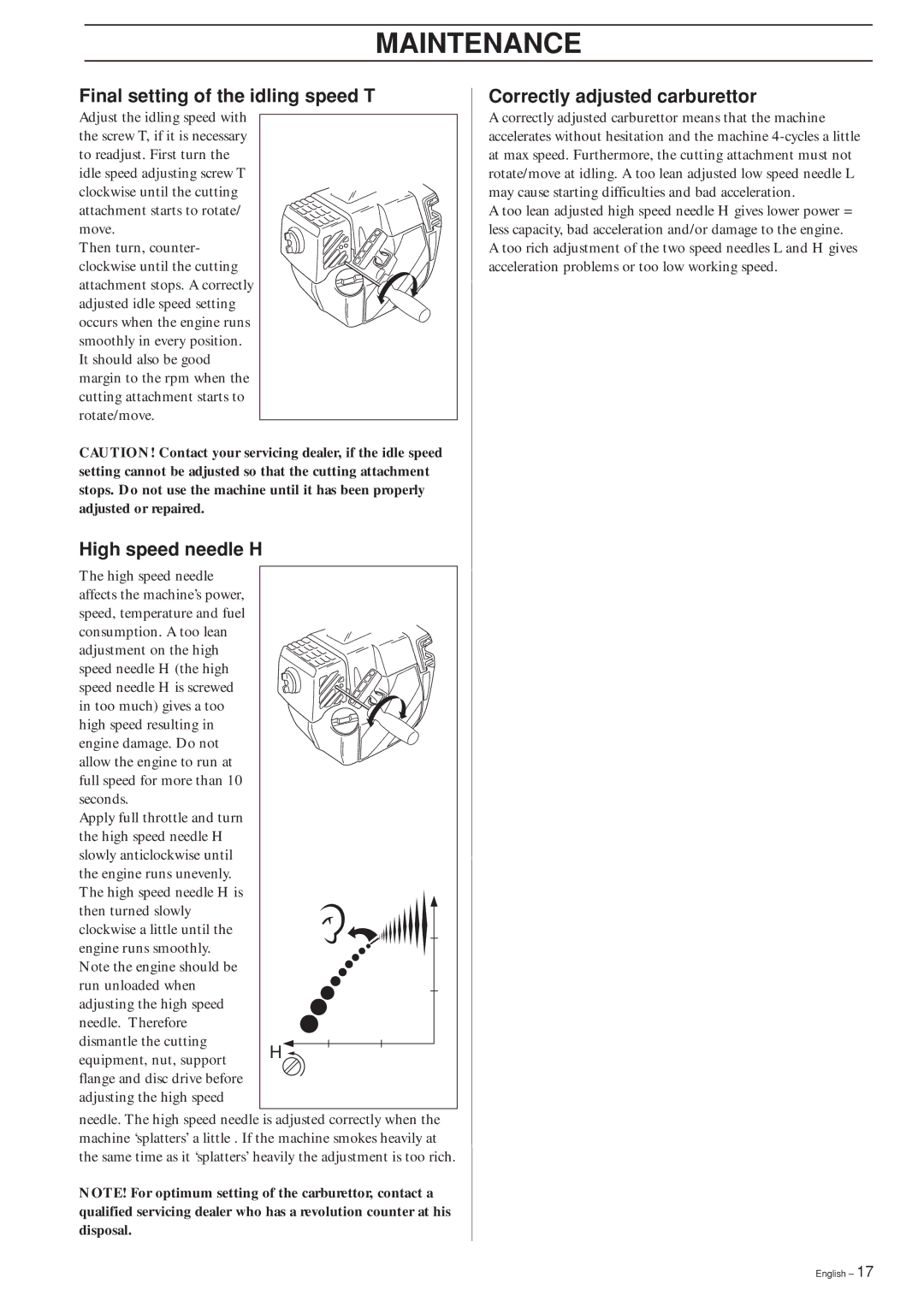

High speed needle H

Correctly adjusted carburettor

A correctly adjusted carburettor means that the machine accelerates without hesitation and the machine

A too lean adjusted high speed needle H gives lower power = less capacity, bad acceleration and/or damage to the engine. A too rich adjustment of the two speed needles L and H gives acceleration problems or too low working speed.

The high speed needle affects the machine’s power, speed, temperature and fuel consumption. A too lean adjustment on the high speed needle H (the high speed needle H is screwed in too much) gives a too high speed resulting in engine damage. Do not allow the engine to run at full speed for more than 10 seconds.

Apply full throttle and turn the high speed needle H slowly anticlockwise until the engine runs unevenly. The high speed needle H is then turned slowly clockwise a little until the engine runs smoothly. Note the engine should be run unloaded when adjusting the high speed needle. Therefore dismantle the cutting equipment, nut, support flange and disc drive before adjusting the high speed

H |

needle. The high speed needle is adjusted correctly when the machine ‘splatters’ a little . If the machine smokes heavily at the same time as it ‘splatters’ heavily the adjustment is too rich.

NOTE! For optimum setting of the carburettor, contact a qualified servicing dealer who has a revolution counter at his disposal.

English – 17