DESCRIPTION

Rails

The rails consist of two sections (standard delivery). Each section is 3 m. The sections are aligned and bolted together into a track for the carriage. The rail sections are bolted together and fastened using M12 bolts with nuts, which assures stability and ensures that the carriage runs straight.

The rails also have a number of transverse log bol- sters, designed to provide a stable support for the log to be cut or the planks to be trimmed.

The rails’ transverse log bolsters are equipped with:

•Folding stop for the log

•Log lock

•Height adjustment of one end of the log

The rails are also fitted with stops at both ends for the saw carriage, as well as adjustable jointing plates on the section joints.

FIG. 12 |

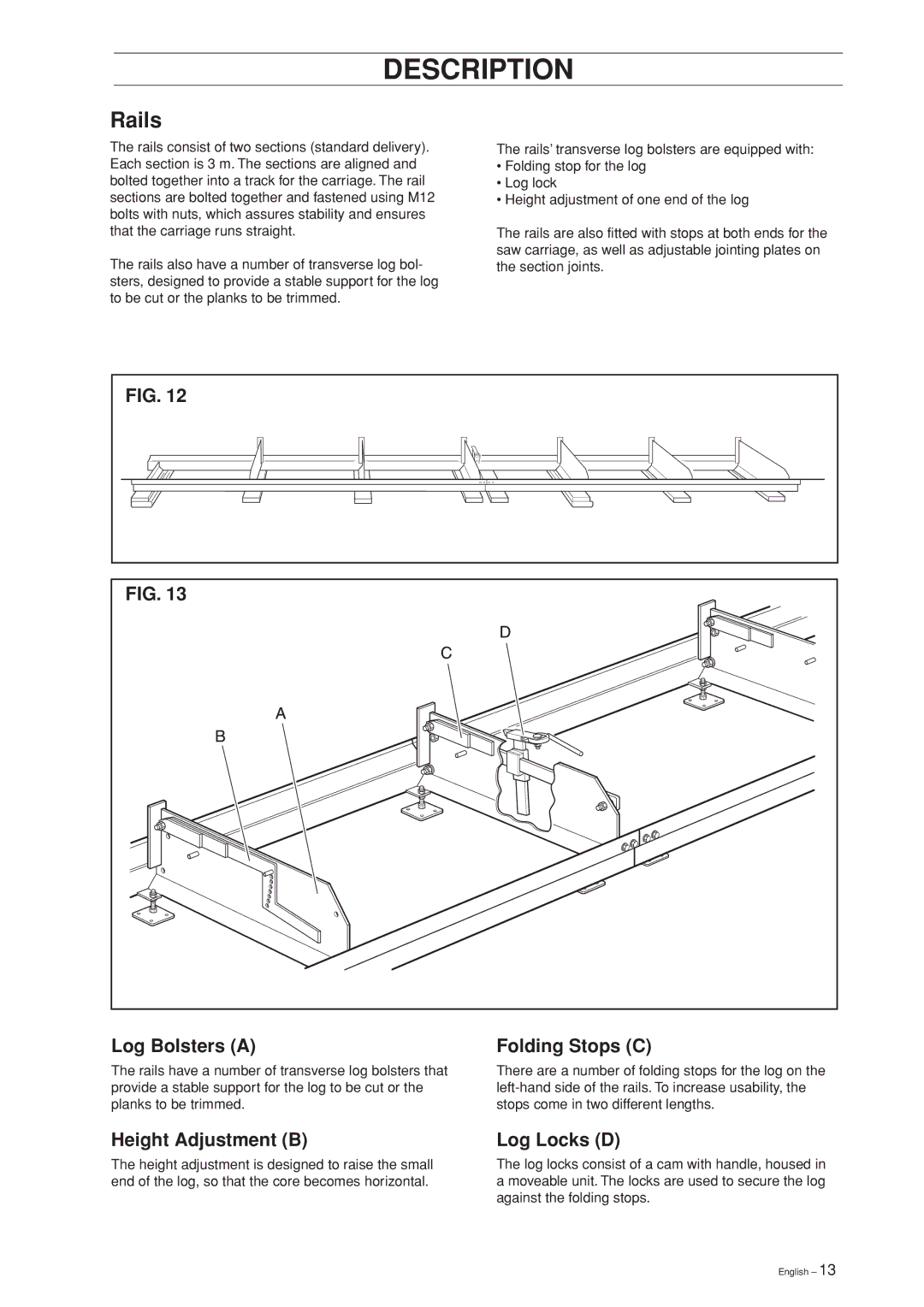

FIG. 13 |

Log Bolsters (A)

The rails have a number of transverse log bolsters that provide a stable support for the log to be cut or the planks to be trimmed.

Folding Stops (C)

There are a number of folding stops for the log on the

Height Adjustment (B)

The height adjustment is designed to raise the small end of the log, so that the core becomes horizontal.

Log Locks (D)

The log locks consist of a cam with handle, housed in a moveable unit. The locks are used to secure the log against the folding stops.

English – 13