Starting and Maintaining a Fire

Burn only solid wood directly on the bottom grate of the stove, do not elevate the fire in any way.

The ash pan door on the stove must always be securely closed when the stove is in operation.

Burning the stove with the ashpan open will

With the primary air control lever in the full open position, start with several sheets of crumbled newspaper placed directly on the grate. On top of the newspaper, place several pieces of small dry kindling (approx. 1” in diameter) with two to three larger logs (approx. 3” to 5” in diameter) on top.

Light the fire and close the door, slowly building the fire by adding larger and larger logs. Be sure to follow the

Once the stove has reached a surface temperature range of between 400° and 600°, adjust the primary air control lever as necessary to generate the heat output and burn time desired.

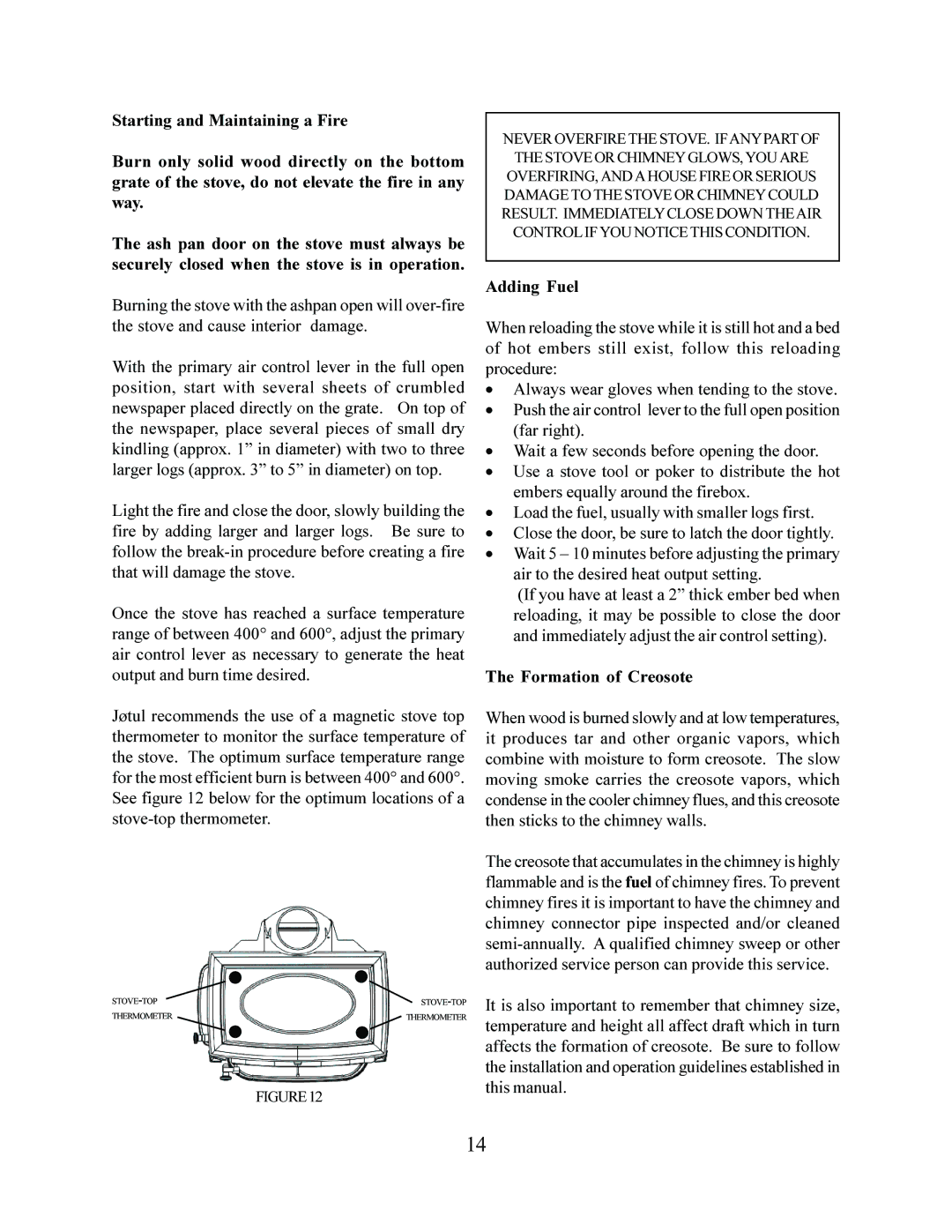

Jøtul recommends the use of a magnetic stove top thermometer to monitor the surface temperature of the stove. The optimum surface temperature range for the most efficient burn is between 400° and 600°. See figure 12 below for the optimum locations of a

THERMOMETER | THERMOMETER |

FIGURE12

NEVER OVERFIRE THE STOVE. IFANYPARTOF THE STOVE OR CHIMNEY GLOWS, YOU ARE OVERFIRING, AND A HOUSE FIRE OR SERIOUS DAMAGE TO THE STOVE OR CHIMNEY COULD RESULT. IMMEDIATELY CLOSE DOWN THEAIR CONTROL IF YOU NOTICE THIS CONDITION.

Adding Fuel

When reloading the stove while it is still hot and a bed of hot embers still exist, follow this reloading procedure:

·Always wear gloves when tending to the stove.

·Push the air control lever to the full open position (far right).

·Wait a few seconds before opening the door.

·Use a stove tool or poker to distribute the hot embers equally around the firebox.

·Load the fuel, usually with smaller logs first.

·Close the door, be sure to latch the door tightly.

·Wait 5 – 10 minutes before adjusting the primary air to the desired heat output setting.

(If you have at least a 2” thick ember bed when reloading, it may be possible to close the door and immediately adjust the air control setting).

The Formation of Creosote

When wood is burned slowly and at low temperatures, it produces tar and other organic vapors, which combine with moisture to form creosote. The slow moving smoke carries the creosote vapors, which condense in the cooler chimney flues, and this creosote then sticks to the chimney walls.

The creosote that accumulates in the chimney is highly flammable and is the fuel of chimney fires. To prevent chimney fires it is important to have the chimney and chimney connector pipe inspected and/or cleaned

It is also important to remember that chimney size, temperature and height all affect draft which in turn affects the formation of creosote. Be sure to follow the installation and operation guidelines established in this manual.

14