SECTION3STEP BY STEP GUIDES TO INSTALL

C. LOCATE WATER SOFTENER,

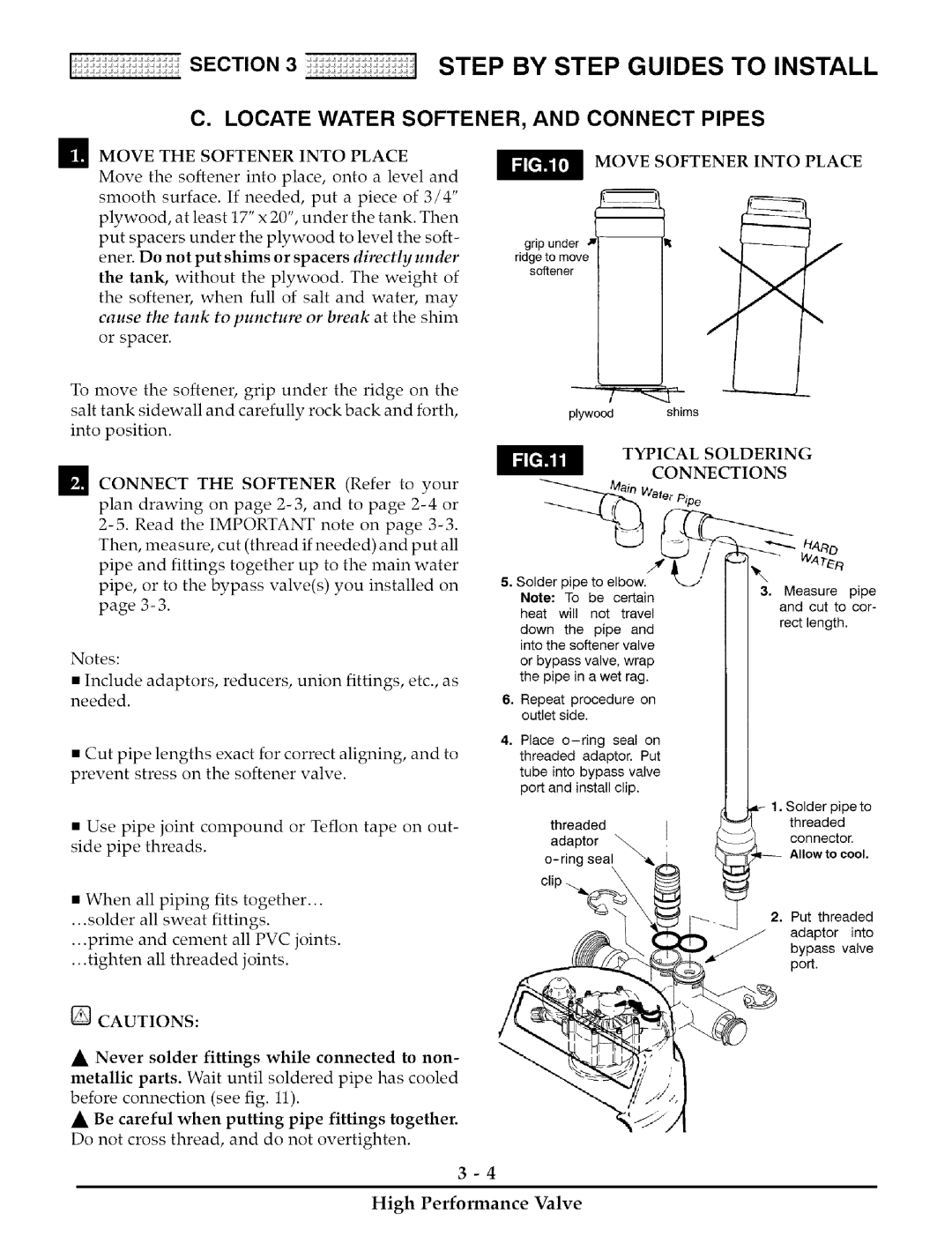

_MOVE THE SOFTENER INTO PLACE

Move the softener into place, onto a level and

smooth surface. If needed, put a piece of 3/4"

plywood, at least 17" x 20", under the tank. Then

put spacers under the plywood to level the soft- ener. Do not put shims or spacers directly under

the tank, without the plywood. The weight of the softener, when full of salt and water, may

cause the tank to puncture or break at the shim or spacer.

AND CONNECT PIPES

MOVE SOFTENER INTO PLACE

To move the softener, grip under the ridge on the salt tank sidewall and carefully rock back and forth, into position.

_J_ CONNECT THE SOFTENER (Refer to your

plan drawing on page

plywoodshims

TYPICAL SOLDERING

CONNECTIONS

pipe and fittings together up to the main water pipe, or to the bypass valve(s) you installed on page 3- 3.

Notes:

• Include adaptors, reducers, union fittings, etc., as needed.

•Cut pipe lengths exact for correct aligning, and to

prevent stress on the softener valve.

•Use pipe joint compound or Teflon tape on out- side pipe threads.

•When all piping fits together...

...solder | all | sweat fittings. | |

...prime | and | cement | all PVC joints. |

...tighten | all | threaded | joints. |

[] CAUTIONS:

• Never solder fittings while connected to non- metallic parts. Wait until soldered pipe has cooled

before connection (see fig. 11).

• Be careful when putting pipe fittings together. Do not cross thread, and do not overtighten.

Water Pipe

5.Solder pipe to elbow. Note: To be certain heat will not travel

down the pipe and into the softener valve

or bypass valve, wrap the pipe in a wet rag.

6.Repeat procedure on outlet side.

4.Place

threaded] adaptor

clip

_v4r_

3. Measure pipe

and cut to cor- rect length.

1.Solder pipe to threaded connector.

Allowto cool.

2.Put threaded adaptor into bypass valve port.