Sears Roebuck and Co., Hoffman Estates, IL 60179 U.S.A

2200128 Sears Canada, Inc., Toronto, Ontario, Canada M5B 2B8

Contents

Your safety and the safety of others is very important

Before you throw away your old refrigerator or freezer

Iiii

Removing packaging materials

Installing Your Refrigerator

Cleaning before use

Remove Screw 1 AS Shown in Diagram

Recommended Grounding Method

Please Read Before Installation

Remove Screw 2 AS Shown in Diagram

Read all directions carefully before you begin

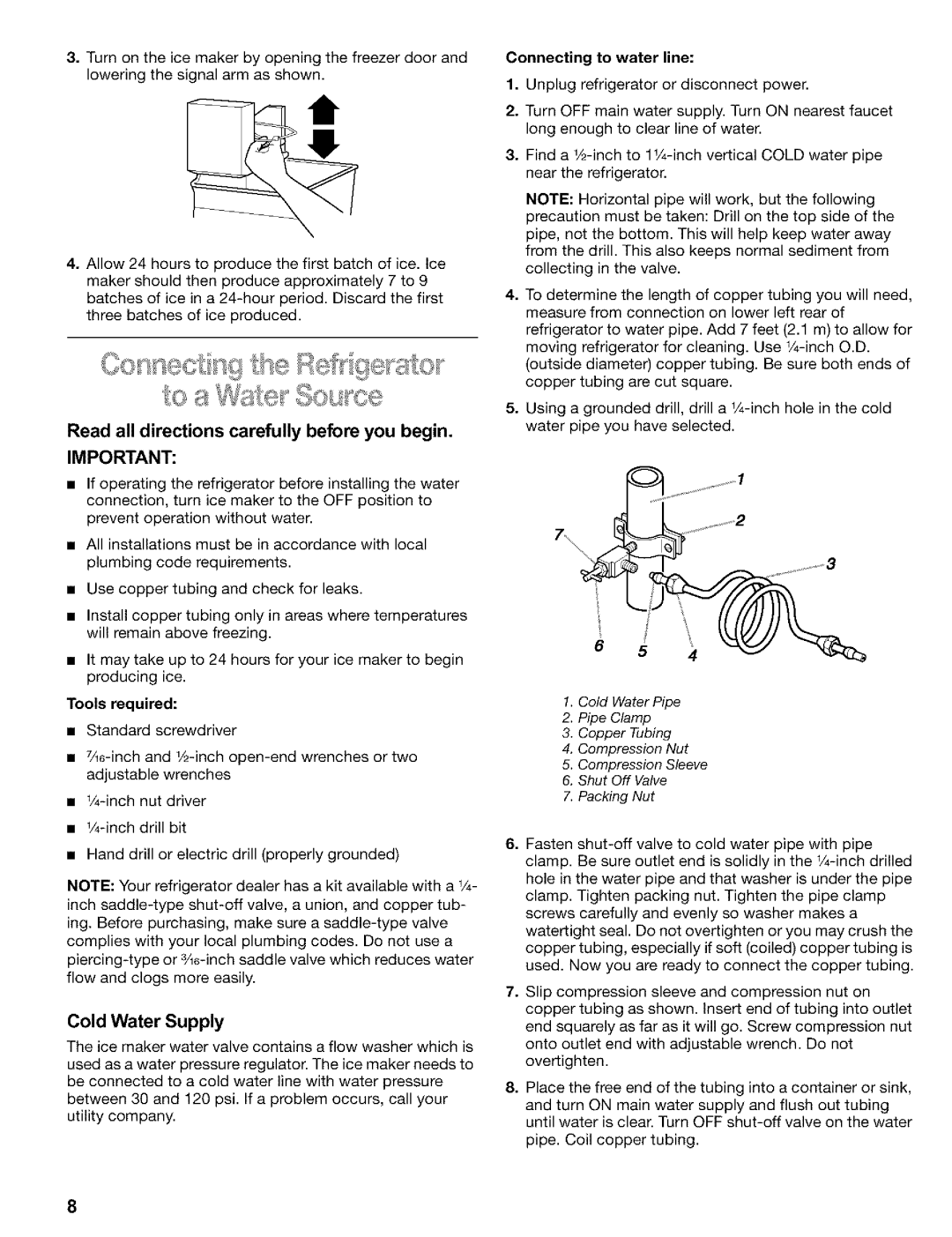

Cold Water Supply

Connecting to refrigerator

Door Closing

Turn shut-off valve ON. Check For Leaks. Tighten any

To remove the base grille

Using Your Refrigerator

Checking airflow

Recommended Adjustment

Storing Fresh Food

CONDITION/REASON

Thermostat

Storing Frozen Food

Refrigerator Features

Ice dispenser

Water dispenser

Dispenser light

Dispenser lock on somemodels

To dispense water

Water filter status light

Changing a water filter cartridge

To replace a shelf/frame

Using the dispenser without the water filter

Ordering replacement filters

To slide the shelf from side to side

To remove the shelf

To replace the shelf

To remove the drawer

To replace the crisper cover

Adjusting the control

To remove the crisper

Snap-on Door Rails

Drop-in Door Rails

Caring for Your Refrigerator

To replace the basket

Explosion Hazard

Energy Saving Tip

Refrigerator light bulbs

Partcomments

If you choose to leave the refrigerator on while youre

Vacations

Moving

Troubleshooting

Lights do not work

There is water in the defrost drain pan

Motor seems to run too much

Refrigerator seems to make too much noise

Ice maker is not producing ice

Ice maker is producing too little ice

Off-taste,odor or grey color in the ice

Divider between the two compartments is warm

Water dispenser will not operate properly

Water or ice is leaking from the dispenser

Temperature is too warm

There is interior moisture build-up

Doors will not close completely

Doors are difficult to open

Sears Maintenance Agreement

Sears Maintenance Agreement

Water Filter Certifications

MCL

Gallons 946 Liters

Maximum Minimum %

Water Filtration System Model LC-400

Maximum

Reduction NSF Test Requirement

Performance tt

Influent

Ndicegaranta

Antes de tirar su refrigerador viejo o congelador

Seguridad DEL Refrigerador

Su seguridad y la seguridad de los demos es muy importante

Partes Y Caractersticas

Cbmo quitar los materiales de empaque

Cbmo limpiar su refrigerador antes de usarlo

Herramientas necesarias

SE Muestra EN EL DIAGRAMA, no Quite EL Tornillo

Metodo de conexibn a tierra recomendado

Muestra EN EL DIAGRAMA, no Quite EL Tornillo

8S B a

Leer las instrucciones con cuidado antes de comenzar

Suministro de agua fria

Importante

Herramientas requeridas

Cierre de la Puerta

Conexibn al refrigerador

Para retirar la rejUla de la base

Para volver a colocar la rejilla

Page

No bloquee ninguno de estos orificios de ventilaci6n

Como Usar SU Refrigerador

Cbmo comprobar el flujo de aire

Almacenamiento de alimentos frescos

Ajuste CONDICIN/MOTIVORECOMENDADO

CONDICIN/MOTIVO

Ajuste Recomendado

Conservacibn de alimentos congelados

El distribuidor de hielo

Para sacar el depbsito de hielo

Para distribuir hielo

Para sacar agua

La luz del distribuidor

El distribuidor de agua

El cierre del distribuidor en algunos modelos

Cbmo cambiar el cartucho de flltracibn de agua

La luz de estado del filtro de agua

Lock UNLOCK1

Estantes deslizables en algunos modelos

Uso del dispensador sin el filtro de agua

Para pedir filtros de repuesto

Estantes y marcos de estantes Para quitar un estante/marco

Para volver a colocar un estante/marco

C6mo deslizar el estante de lado a lado

Para quitar el estante

Cbmo ajustar el control

Para volver a colocar el estante

Para sacar el cajbn convertible

Para sacar la tapa

Jlg. I0... I I..+0 ... OS

Para sacar el compartimiento de verduras

Rieles del a puerta a presi6n

Rieles calzables de la puerta

Cbmo retirar el cajbn para carnes frias

Para volver a colocar los rieles

Cuidado DE SU Refrigerador

Comentarios

Focos del refrigerador

Parte

Luz superior del congelador en algunos modelos

Focos del congelador

La luz que estb debajo del depbsito de hielo

Vacaciones

Mudanza

Localizacion Y Reparacion DE Averas

Parece que el motor funciona excesivamente

Las luces no funcionan

El refrigerador parece Hacer mucho ruido

La fabrica de hielo no produce hielo

La fabrica de hielo produce muy poco hielo

El hielo tiene mal sabor, mal olor o un color grisceo

El despachador de hielo no funciona debidamente

El despachador de agua no funciona debidamente

Hay filtracibn de agua o hielo en el despachador

El agua del despachador no est Io suficientemente fria

El divisor entre los dos compartimientos est caliente

La temperatura est muy caliente

Hay acumulacibn de humedad en el interior

Las puertas no cierran completamente

Es dificil abrir las puertas

Contrato DE Mantenimiento Sears

Contrato de mantenimiento Sears

El contrato de mantenimiento Sears

Le damos servicio a Io que vendemos es nuestro

Certificacion DE Filtros DE Agua

Litros 250 galones

Sistema de Filtrado de Agua Modelo LC-400

Litros 400 galones

Litros 500 galones

Minimo %

Ximo Minimo %

Contaminatestt

Garantie

SI Curiti DU RI Frigi Rateur

Votre sdcuritd et celle des autres est tres importante

Avant de jeter votre vieux rdfrigdrateur ou

Congdlateur

PII=CES ET CARACTI!RISTIQUES

Nettoyage avant rutilisation

Installation DU RI Frigi Rateur

Enlevement des matdriaux demballage

PAS Enlever a LA VIS 1, TEL Quindiqu Dans LE Schima

Methode recommandde de mise a la terre

Outils requis

PAS Enlever LA VlS 2 TEL Quillustri Dans LE Schema

NE PAS Enlever LA VIS 3 TEL Quillustri Dans LE Schema

Arrivde deau froide

Raccordement b une canalisation deau

Raccordement au rfrigrateur

Pour replacer la grille

Fermeture des portes

Recommandd, ne refroidira pas les compartiments plus vite

Utilisation DU RI Frigi Rateur

Verification de la circulation dair

Ne pas obstruer lunede ces ouvertures daration

CONDITION/RAISON

Ajustement Recommandie

Conservation des aliments frais

Conservation des aliments congels

Pour retirer le bac de glaons

CARACTI!RISTIQUES DU RI Frigi Rateur

Le distributeur de glaqons

Le distributeur deau

Temoin lumineux du distributeur

Distribution de glaqons

Distribution deau

Remplacement de la cartouche de filtre a eau

Le temoin lumineux de Ietatdu filtre a eau

Pour retirer les tablettes de la position dexp6dition

Commande de flltres de rechange

Utilisation de la fontaine refrigqree sans filtre Eau

Pour r6installer un cadre de tablette

Tablettes sur roulettes sur certains modeles

Pour glisser la tablette dunc6t & lautre

Pour enlever la tablette

Pour reinstaller la tablette

Ajustement du rdglage

Pour retirer le couvercle

Pour replacer le couvercle

Pour retirer le bac b Igumes

Pour retirer le couvercle du bac b lgumes

Pour enlever Iextension du couvercle du bac b ldgumes

Pour remettre Iextension du couvercle du bac ldgumes

Tringles dposes dans la porte

Tringles enclenchables dans la porte

Pour r6installer le panier

Entretien DE Votre RI Frigi Rateur

Pour retirer le panier du congdlateur

Conseil pour 6conomie d6nergie

Ampoules ddclairage du rdfrigdrateur

Piecescommentaires

Ampoules dclairage du conglateur

Pour enlever le protecteur de Iampoule pour le nettoyage

Lumire au-dessous du bac & glagons

Heures

Vacances

Dmnagement

Les ampoules nclairent pas

Guide DE DI Pannage

Le moteur semble fonctionner excessivement

La machine b glacons ne produit pas de glaqons

La machine a glaqons produit trop peu de glaqons

Mauvais got ou odeur des glaqons

Le distributeur de glacr.Onsne fonctionne pas correctement

Le distributeur deau ne fonctionne pas correctement

Leauou la glace coule du distributeur

Leaudu distributeur nest pas assez froide

La cloison entre les deux sections est tiede

La tempdrature est trop tiede

II existe une accumulation dhumiditd b Iinterieur

Les portes ne se ferment pas completement

Les portes sont difficiles b ouvrir

Service Dentretiensears

Contrat dentretien Sears

Le contrat dentretien Sears

Nous faisons Ientretien des produits que nous

Certifications DE Filtre .&.EAU

946 Liters 250 Gallons

Liters 400 gallons

NSF

Liters 500 gallons

Rendement Affluent moyen

Gnral Moyen Minimal Rduction

Contaminanttt

MY-HOM E

2200128