Service Tech Information

ROTARY VALVE SERVICE

IMPORTANT: Before working on the valve, turn off the water supply and disconnect from electrical power.

TO RELIEVE PRESSURE:

•3 VALVE BYPASS: Close the inlet valve and open a soft water faucet. Then close the outlet valve and open the bypass valve.

•SEARS SPECIAL BYPASS: Slide the bypass valve stem to bypass position. Loosen three hex head screws toward the back side of the valve to allow pressure water to bleed out. Catch water with a rag.

DISASSEMBLY

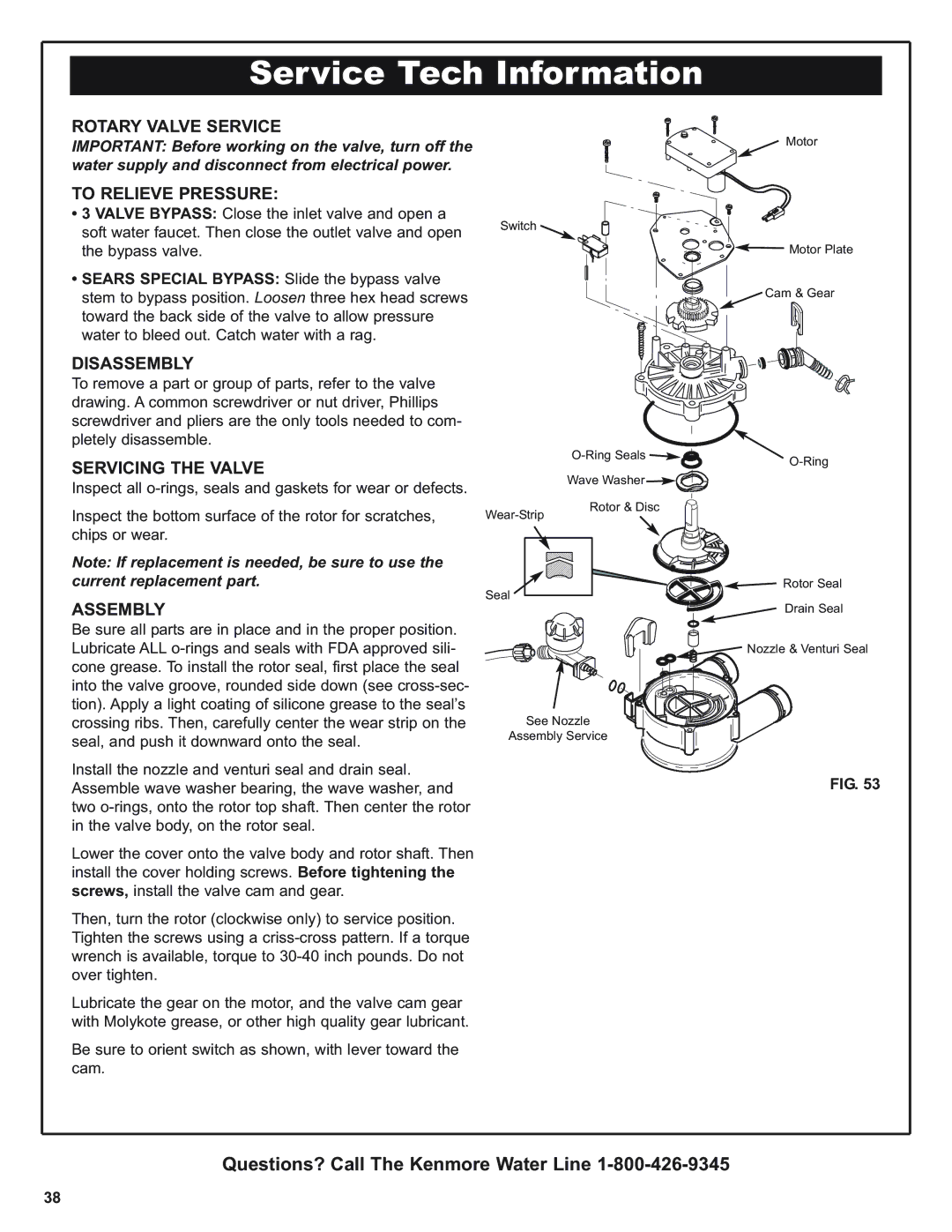

To remove a part or group of parts, refer to the valve drawing. A common screwdriver or nut driver, Phillips screwdriver and pliers are the only tools needed to com- pletely disassemble.

SERVICING THE VALVE

Inspect all

Inspect the bottom surface of the rotor for scratches, chips or wear.

Note: If replacement is needed, be sure to use the current replacement part.

ASSEMBLY

Be sure all parts are in place and in the proper position. Lubricate ALL

Install the nozzle and venturi seal and drain seal. Assemble wave washer bearing, the wave washer, and two

Lower the cover onto the valve body and rotor shaft. Then install the cover holding screws. Before tightening the screws, install the valve cam and gear.

Then, turn the rotor (clockwise only) to service position. Tighten the screws using a

Lubricate the gear on the motor, and the valve cam gear with Molykote grease, or other high quality gear lubricant.

Be sure to orient switch as shown, with lever toward the cam.

![]() Motor

Motor

Switch ![]()

![]() Motor Plate

Motor Plate

![]() Cam & Gear

Cam & Gear

| ||

|

| |

| Wave Washer |

|

Rotor & Disc |

| |

|

| |

Seal |

| Rotor Seal |

|

| |

|

| Drain Seal |

|

| Nozzle & Venturi Seal |

See Nozzle

Assembly Service

FIG. 53

Questions? Call The Kenmore Water Line

38