1.PlaceboilerintheselecledIocalion(asnearchimneyaspossibleYour.) boilerisshippedassembledYouneedonlyIoinsfall.theReliefValveand

adrainlineto carryanywalerorsteamIo adrain.

2.InstallRelielValveinto

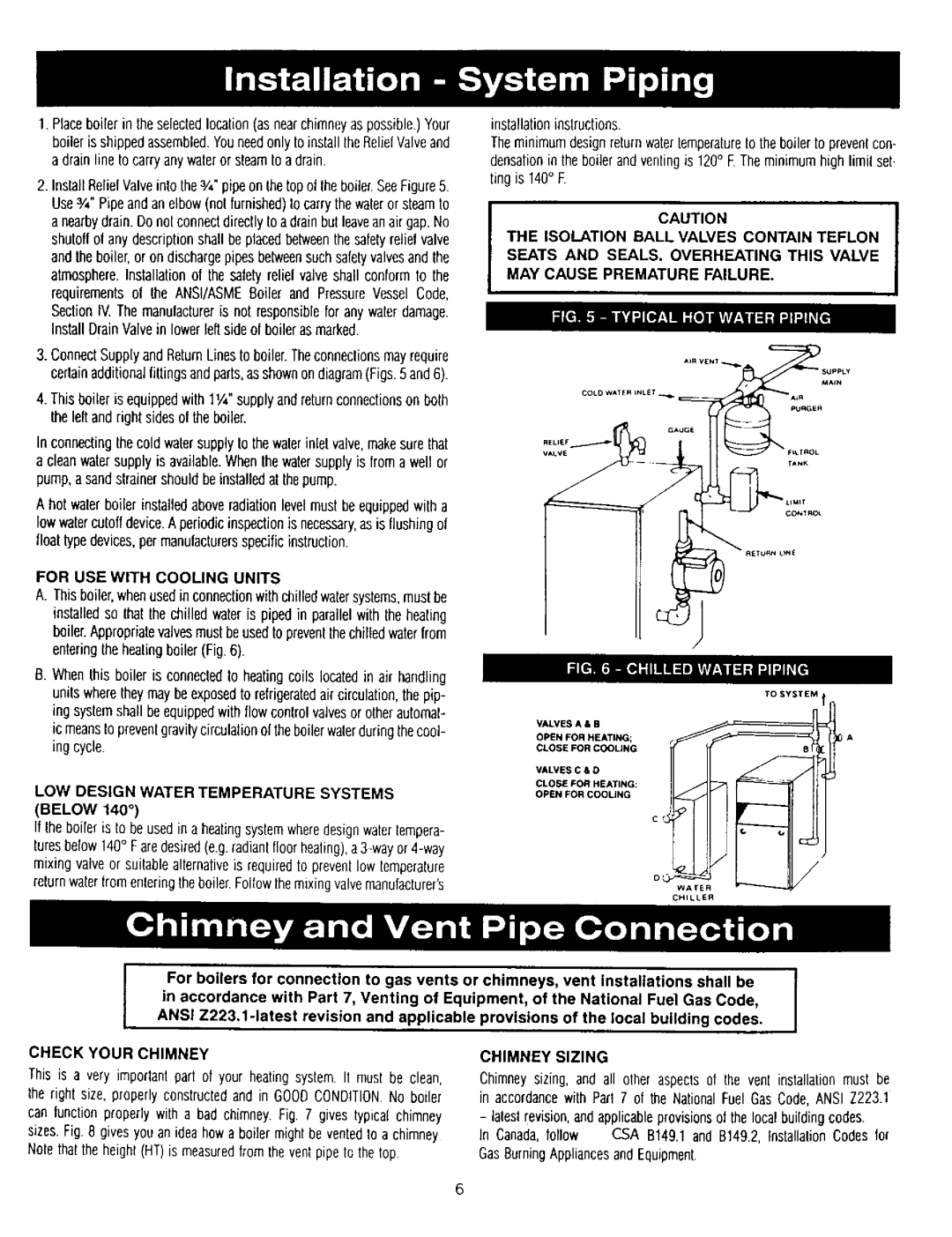

3.ConnectSupplyandReturnLinesto boiler.Theconneclionsmayrequire certainadditionalfiltingsandparts,as shownondiagram(Figs.5and6).

4.Thisboileris equippedwilh 11/4"supplyandreturnconnectionsonboth theleftandrightsidesol the boiler.

installationinstructions. TheminimumdesignreturnwaterLemperatureIo theboilerto prevenlcon- densationin theboilerandventingis 120° E Theminimumhigh limil set- ting is 140° F.

THE ISOLATION BALL VALVES CONTAIN TEFLON

SEATS AND SEALS. OVERHEATING THIS VALVE

ICAUTION

MAY CAUSE PREMATURE FAILURE.

COt.o WATE_ LNLET.

In connectingthecoldwatersupplytothewalerinlelvalve,makesurethat a cleanwalersupplyis availableWhen.thewatersupplyis froma weftor pump,asandstrainershouldbeinstalledat thepump.

A hot walerboiler installedaboveradiationlevelmustbeequippedwilh a lowwatercutoffdeviceA. periodicinspectionis necessary,as is flushingof floattypedevices,permanufacturersspecificinstruction.

FOR USE WITH COOUNG UNITS

A.Thisboiler,whenusedinconnectionwithchilledwatersystems,mustbe installedso that thechilled wateris pipedin parallelwith theheating boiler.Appropriatevalvesmustbeused1oprevenlthechilledwaterfrom enteringtheheatingboiler(Fig.6).

B.Whenthisboiler is connectedto heatingcoils locatedin air handling

unitswheretheymaybeexposedto refrigeratedaircirculation,thepip- ing syslemshallbeequippedwithflowcontrolvalvesorotherautomaf-

ic meansto prevenlgravgycirculationof theboilerwalerduringthecool- ing cycle.

TO SYSTEM

VALVES A & B

OPEN FOR HEATING;

CLOSE FOR COOLING

VALVES C & O

LOW DESIGN WATER TEMPERATURE SYSTEMS

(BELOW 140 °)

If Iheboileris to beusedin aheatingsysfemwheredesignwaterlempera- luresbelow140°

CLOSE FOR HEATING:

OPEN FOR COOLING

c d

WAFER

CHILLER

For boilers for connection to gas vents or chimneys, vent Installations shall be in accordance with Part 7, Venting of Equipment, of the National Fue Gas Code, ANSI

CHECK YOUR CHIMNEY

Thisis a very imporfantpart of your heatingsystem It must be clean, theright size, properlyconstructedandin GOODCONDITIONNo boiler can lunctionproperlywith a bad chimney.Fig. 7 givestypical chimney sizes.Fig.8 givesyouanideahowa boilermightbe ventedto achimney Nofetha_theheight(HT)is measuredfromtheventpipeto the lop.

CHIMNEY SIZING

Chimneysizing, and all other aspectsof the vent installationmust be in accordancewith Part 7 of the NationalFuelGasCode,ANSIZ223.1 - laleslrevision,andapplicableprovisionsof the localbuildingcodes.

In Canada,follow CSA B149.1and B149.2,InstallabonCodesfor GasBurningAppliancesandEquipment.

6