Recovery

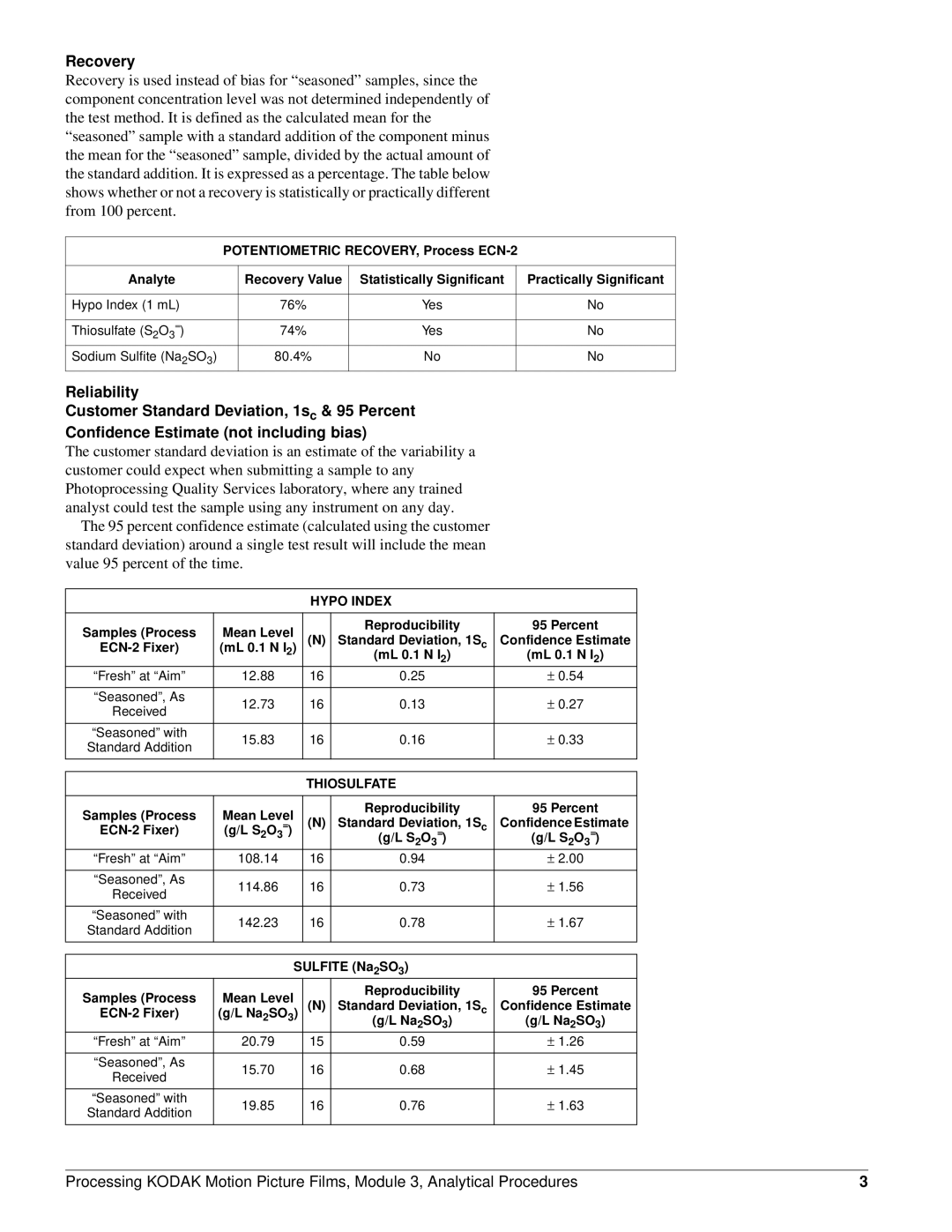

Recovery is used instead of bias for “seasoned” samples, since the component concentration level was not determined independently of the test method. It is defined as the calculated mean for the “seasoned” sample with a standard addition of the component minus the mean for the “seasoned” sample, divided by the actual amount of the standard addition. It is expressed as a percentage. The table below shows whether or not a recovery is statistically or practically different from 100 percent.

POTENTIOMETRIC RECOVERY, Process

Analyte | Recovery Value | Statistically Significant | Practically Significant |

|

|

|

|

Hypo Index (1 mL) | 76% | Yes | No |

|

|

|

|

Thiosulfate (S2O3=) | 74% | Yes | No |

|

|

|

|

Sodium Sulfite (Na2SO3) | 80.4% | No | No |

|

|

|

|

Reliability

Customer Standard Deviation, 1sc & 95 Percent

Confidence Estimate (not including bias)

The customer standard deviation is an estimate of the variability a customer could expect when submitting a sample to any Photoprocessing Quality Services laboratory, where any trained analyst could test the sample using any instrument on any day.

The 95 percent confidence estimate (calculated using the customer standard deviation) around a single test result will include the mean value 95 percent of the time.

HYPO INDEX

Samples (Process | Mean Level |

| Reproducibility | 95 Percent | ||

(N) | Standard Deviation, 1Sc | Confidence Estimate | ||||

(mL 0.1 N I2) | ||||||

| (mL 0.1 N I2) | (mL 0.1 N I2) | ||||

|

|

| ||||

“Fresh” at “Aim” | 12.88 | 16 | 0.25 | ± | 0.54 | |

|

|

|

|

|

| |

“Seasoned”, As | 12.73 | 16 | 0.13 | ± | 0.27 | |

Received | ||||||

|

|

|

|

| ||

|

|

|

|

|

| |

“Seasoned” with | 15.83 | 16 | 0.16 | ± | 0.33 | |

Standard Addition | ||||||

|

|

|

|

| ||

|

|

|

|

|

| |

|

|

|

|

| ||

|

| THIOSULFATE |

|

| ||

|

|

|

|

| ||

Samples (Process | Mean Level |

| Reproducibility | 95 Percent | ||

(N) | Standard Deviation, 1Sc | Confidence Estimate | ||||

= | ||||||

(g/L S2O3 ) |

| = |

| = | ||

|

|

| (g/L S2O3 ) | (g/L S2O3 ) | ||

“Fresh” at “Aim” | 108.14 | 16 | 0.94 | ± | 2.00 | |

|

|

|

|

|

| |

“Seasoned”, As | 114.86 | 16 | 0.73 | ± | 1.56 | |

Received | ||||||

|

|

|

|

| ||

|

|

|

|

|

| |

“Seasoned” with | 142.23 | 16 | 0.78 | ± | 1.67 | |

Standard Addition | ||||||

|

|

|

|

| ||

|

|

|

|

|

| |

|

|

|

| |||

| SULFITE (Na2SO3) |

|

| |||

Samples (Process | Mean Level |

| Reproducibility | 95 Percent | ||

(N) | Standard Deviation, 1Sc | Confidence Estimate | ||||

(g/L Na2SO3) | ||||||

| (g/L Na2SO3) | (g/L Na2SO3) | ||||

|

|

| ||||

“Fresh” at “Aim” | 20.79 | 15 | 0.59 | ± | 1.26 | |

|

|

|

|

|

| |

“Seasoned”, As | 15.70 | 16 | 0.68 | ± | 1.45 | |

Received | ||||||

|

|

|

|

| ||

|

|

|

|

|

| |

“Seasoned” with | 19.85 | 16 | 0.76 | ± | 1.63 | |

Standard Addition | ||||||

|

|

|

|

| ||

|

|

|

|

|

| |

Processing KODAK Motion Picture Films, Module 3, Analytical Procedures | 3 |