CFI230J specifications

The Kohler CFI230J is a versatile and powerful engine designed to meet the demanding needs of various applications, primarily in the commercial sector. What sets this engine apart is its combination of advanced engineering, innovative technology, and robust performance characteristics, making it ideal for landscaping, construction, and agricultural tasks.One of the standout features of the CFI230J is its dependable performance. This engine boasts a 23-horsepower output, allowing it to tackle heavy workloads with ease. The overhead valve design ensures efficient combustion and enhances fuel economy, which is crucial for both cost savings and environmental considerations.

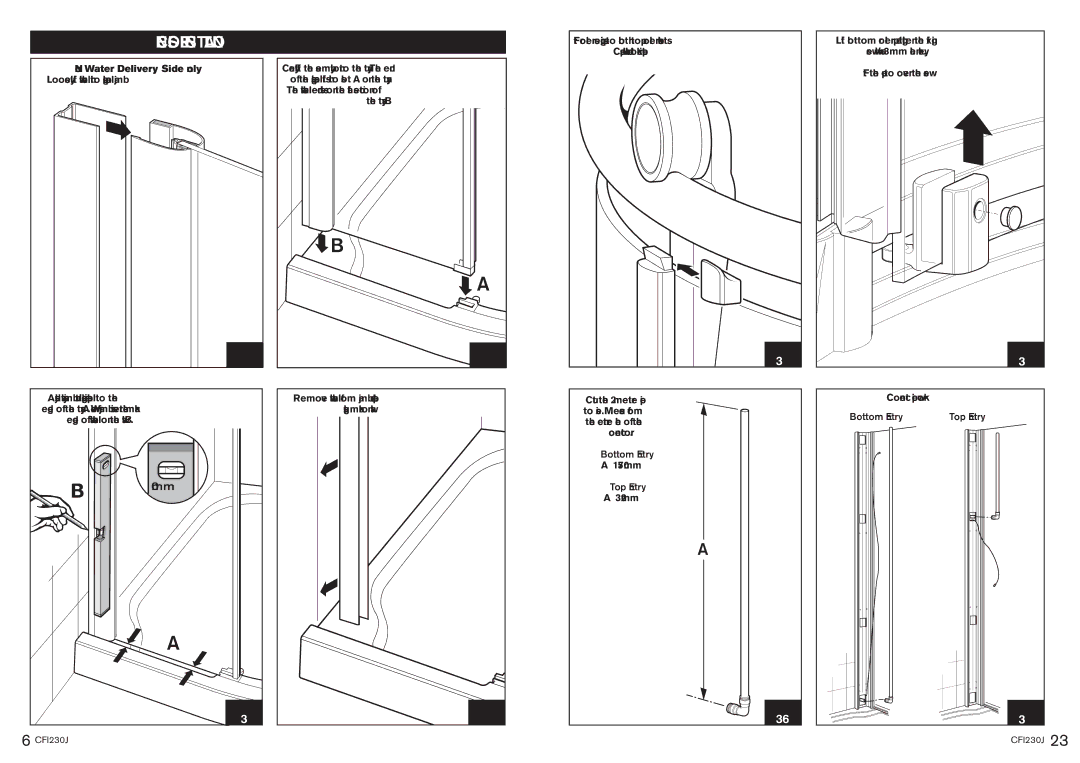

The CFI230J is equipped with a reliable, recoil start system, ensuring quick and dependable starts in various weather conditions. Additionally, its heavy-duty air filtration system keeps the engine protected from harmful debris, prolonging its lifecycle and maintaining optimum performance over time.

Kohler has integrated advanced technologies into the CFI230J to further enhance its capabilities. One of these technologies is the Integrated Oil Filter, which ensures that the engine runs smoothly and efficiently by maintaining clean oil circulation. This reduces maintenance intervals and extends the time between oil changes, which is advantageous for busy professionals who rely on their equipment.

Moreover, the CFI230J features a highly durable construction, with a sturdy aluminum die-cast design that minimizes weight while maximizing strength. This makes the engine not only robust but also easier to handle in various mounting scenarios. The heavy-duty components ensure longevity, making it an excellent long-term investment for users.

Another defining characteristic of the Kohler CFI230J is its user-friendly design. Accessibility for maintenance and service is a priority, allowing users to perform routine checks and repairs with minimal hassle. This user-centric approach is appreciated in commercial settings where time is of the essence.

In summary, the Kohler CFI230J offers an impressive blend of power, efficiency, and durability. Its advanced technologies, robust construction, and ease of maintenance make it an ideal choice for professionals looking to maximize productivity in demanding environments. Whether for landscaping or construction, this engine is ready to perform, ensuring reliability and efficiency every step of the way.