Important: If necessary, adjust the stitching length and cutting width.

Hem stitching

Edging

Differential feed motion

With the differential feed motion uneven seams are avoided in knitted materials, as well as the slippage of textile positions. Additionally, the seams cause no wrinkles in very light materials.

Manner of operation

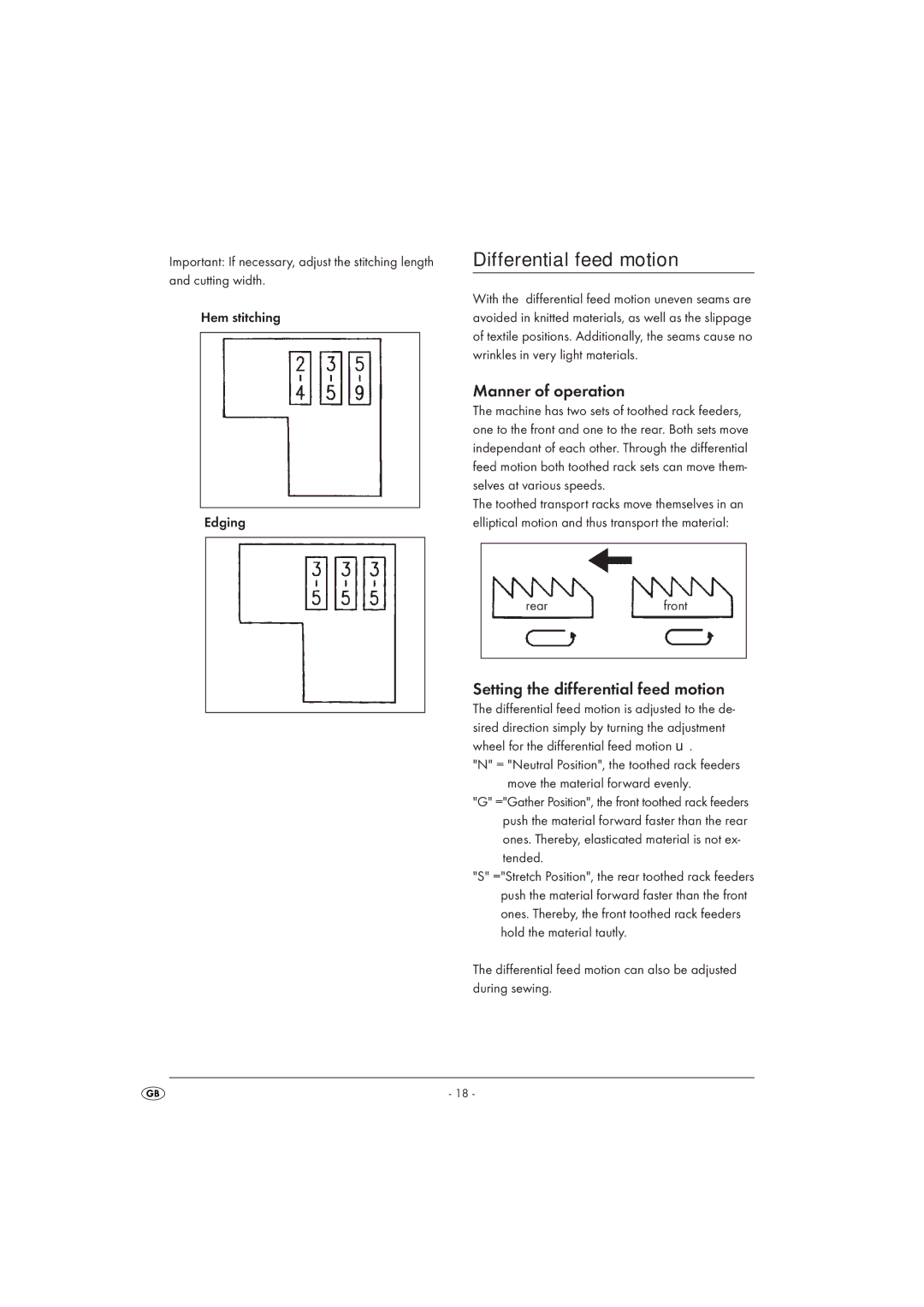

The machine has two sets of toothed rack feeders, one to the front and one to the rear. Both sets move independant of each other. Through the differential feed motion both toothed rack sets can move them- selves at various speeds.

The toothed transport racks move themselves in an elliptical motion and thus transport the material:

rearfront

Setting the differential feed motion

The differential feed motion is adjusted to the de- sired direction simply by turning the adjustment wheel for the differential feed motion u.

"N" = "Neutral Position", the toothed rack feeders move the material forward evenly.

"G" ="Gather Position", the front toothed rack feeders push the material forward faster than the rear ones. Thereby, elasticated material is not ex- tended.

"S" ="Stretch Position", the rear toothed rack feeders push the material forward faster than the front ones. Thereby, the front toothed rack feeders hold the material tautly.

The differential feed motion can also be adjusted during sewing.

- 18 -