Installing Indoor Metering Device

This outdoor unit is designed for use in systems that use either an fixed orifice (RFC) (included with outdoor unit), or expansion valve metering device (purchased separately) at the indoor coil.

See the Lennox 14ACX Engineering Handbook for approved expansion valve kit match ups. The expansion valve unit can be installed internal or external to the indoor

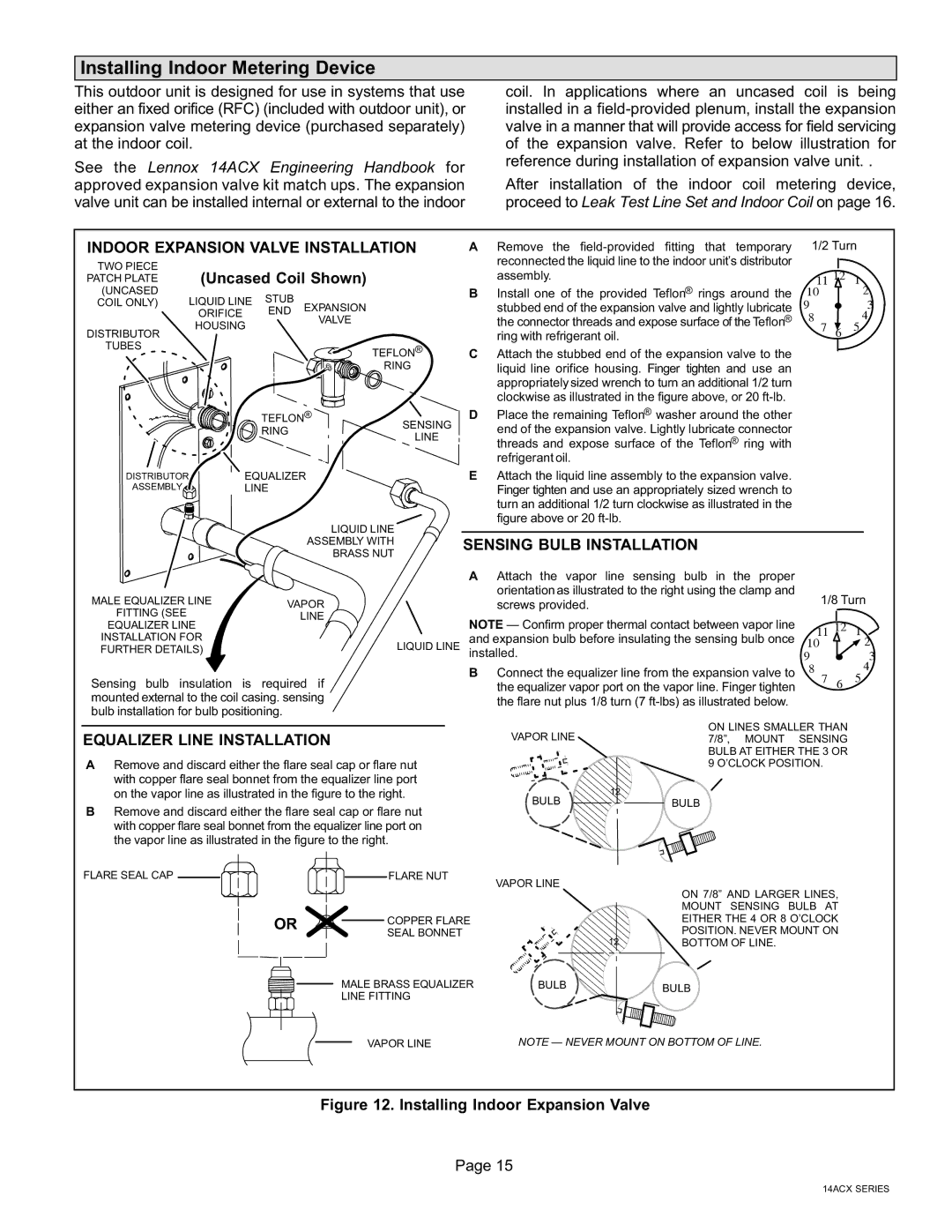

coil. In applications where an uncased coil is being installed in a field−provided plenum, install the expansion valve in a manner that will provide access for field servicing of the expansion valve. Refer to below illustration for reference during installation of expansion valve unit. .

After installation of the indoor coil metering device, proceed to Leak Test Line Set and Indoor Coil on page 16.

INDOOR EXPANSION VALVE INSTALLATION

TWO PIECE | (Uncased Coil Shown) |

| ||

PATCH PLATE |

| |||

(UNCASED |

| STUB |

|

|

COIL ONLY) | LIQUID LINE | EXPANSION |

| |

END |

| |||

| ORIFICE |

| ||

| VALVE |

| ||

|

|

| ||

| HOUSING |

|

| |

DISTRIBUTOR |

|

|

| |

|

|

|

| |

TUBES |

|

|

| TEFLON® |

|

|

|

| |

|

|

|

| RING |

|

| TEFLON® | SENSING | |

|

| RING |

| |

|

|

| LINE | |

|

|

|

| |

ARemove the field−provided fitting that temporary reconnected the liquid line to the indoor unit’s distributor assembly.

BInstall one of the provided Teflon® rings around the

stubbed end of the expansion valve and lightly lubricate the connector threads and expose surface of the Teflon® ring with refrigerant oil.

CAttach the stubbed end of the expansion valve to the liquid line orifice housing. Finger tighten and use an appropriately sized wrench to turn an additional 1/2 turn clockwise as illustrated in the figure above, or 20 ft−lb.

DPlace the remaining Teflon® washer around the other end of the expansion valve. Lightly lubricate connector threads and expose surface of the Teflon® ring with refrigerant oil.

1/2 Turn

11 12 | 1 | |

10 |

| 2 |

9 |

| 43 |

8 7 | 6 | 5 |

DISTRIBUTOREQUALIZER

ASSEMBLY![]() LINE

LINE

LIQUID LINE

ASSEMBLY WITH

BRASS NUT

EAttach the liquid line assembly to the expansion valve. Finger tighten and use an appropriately sized wrench to turn an additional 1/2 turn clockwise as illustrated in the figure above or 20 ft−lb.

SENSING BULB INSTALLATION

MALE EQUALIZER LINE | VAPOR | |

FITTING (SEE | ||

LINE | ||

EQUALIZER LINE | ||

| ||

INSTALLATION FOR |

| |

FURTHER DETAILS) |

|

Sensing bulb insulation is required if mounted external to the coil casing. sensing bulb installation for bulb positioning.

AAttach the vapor line sensing bulb in the proper orientation as illustrated to the right using the clamp and screws provided.

NOTE

and expansion bulb before insulating the sensing bulb once LIQUID LINE installed.

BConnect the equalizer line from the expansion valve to the equalizer vapor port on the vapor line. Finger tighten the flare nut plus 1/8 turn (7 ft−lbs) as illustrated below.

| 1/8 Turn | ||

| 11 12 | 1 | |

10 |

| 2 | |

9 |

|

| 43 |

8 | 7 | 6 | 5 |

EQUALIZER LINE INSTALLATION

ARemove and discard either the flare seal cap or flare nut with copper flare seal bonnet from the equalizer line port on the vapor line as illustrated in the figure to the right.

BRemove and discard either the flare seal cap or flare nut with copper flare seal bonnet from the equalizer line port on the vapor line as illustrated in the figure to the right.

VAPOR LINE | ON LINES SMALLER THAN |

7/8", MOUNT SENSING | |

| BULB AT EITHER THE 3 OR |

| 9 O’CLOCK POSITION. |

| 12 |

BULB | BULB |

FLARE SEAL CAP ![]()

![]()

![]()

![]()

![]()

![]()

OR

FLARE NUT | VAPOR LINE |

|

|

| |

|

| ON 7/8" AND LARGER LINES, |

|

| MOUNT SENSING BULB AT |

COPPER FLARE |

| EITHER THE 4 OR 8 O’CLOCK |

SEAL BONNET | 12 | POSITION. NEVER MOUNT ON |

| BOTTOM OF LINE. | |

MALE BRASS EQUALIZER | BULB | BULB |

LINE FITTING |

| |

|

|

VAPOR LINE | NOTE OM OF LINE. |

Figure 12. Installing Indoor Expansion Valve

Page 15

14ACX SERIES