PRODUCT FEATURES AND CONTROLS

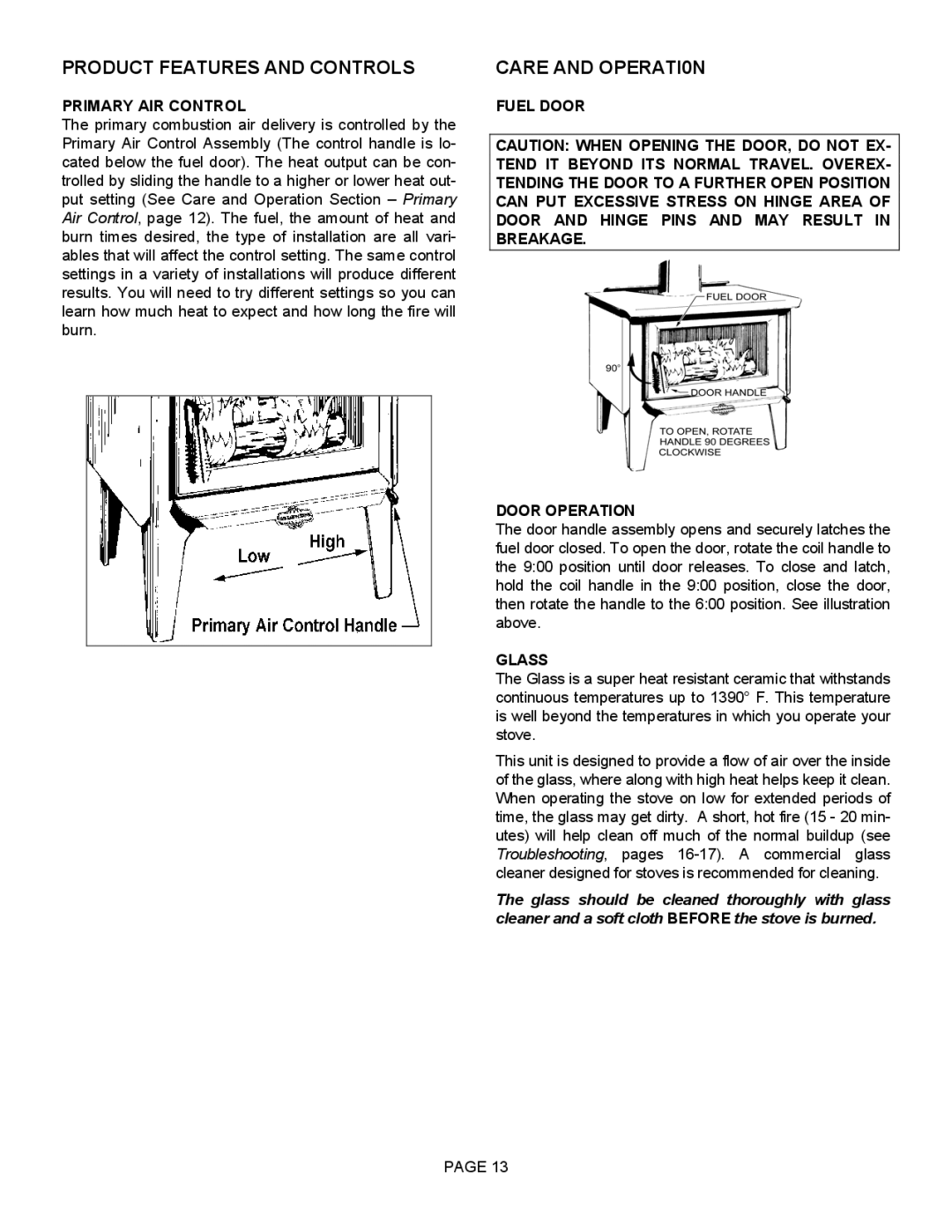

PRIMARY AIR CONTROL

The primary combustion air delivery is controlled by the Primary Air Control Assembly (The control handle is lo- cated below the fuel door). The heat output can be con- trolled by sliding the handle to a higher or lower heat out- put setting (See Care and Operation Section – Primary Air Control, page 12). The fuel, the amount of heat and burn times desired, the type of installation are all vari- ables that will affect the control setting. The same control settings in a variety of installations will produce different results. You will need to try different settings so you can learn how much heat to expect and how long the fire will burn.

CARE AND OPERATI0N

FUEL DOOR

CAUTION: WHEN OPENING THE DOOR, DO NOT EX- TEND IT BEYOND ITS NORMAL TRAVEL. OVEREX- TENDING THE DOOR TO A FURTHER OPEN POSITION CAN PUT EXCESSIVE STRESS ON HINGE AREA OF DOOR AND HINGE PINS AND MAY RESULT IN BREAKAGE.

DOOR OPERATION

The door handle assembly opens and securely latches the fuel door closed. To open the door, rotate the coil handle to the 9:00 position until door releases. To close and latch, hold the coil handle in the 9:00 position, close the door, then rotate the handle to the 6:00 position. See illustration above.

GLASS

The Glass is a super heat resistant ceramic that withstands continuous temperatures up to 1390° F. This temperature is well beyond the temperatures in which you operate your stove.

This unit is designed to provide a flow of air over the inside of the glass, where along with high heat helps keep it clean. When operating the stove on low for extended periods of time, the glass may get dirty. A short, hot fire (15 - 20 min- utes) will help clean off much of the normal buildup (see Troubleshooting, pages

The glass should be cleaned thoroughly with glass cleaner and a soft cloth BEFORE the stove is burned.

PAGE 13