B-3 OPERATIONB-3

IDLER OPERATION

Start the engine with the “Idler” switch in the “High” position. Allow it to run at high idle speed for several minutes to warm the engine. See Specifications for operating speeds.

The idler is controlled by the “Idler” toggle switch on the welder control panel. The switch has two posi- tions as follows:

1.In the “High” ![]() position, the engine control unit increases the engine to high idle speed.

position, the engine control unit increases the engine to high idle speed.

2.In the “Auto” ![]() /

/ ![]() position, the idler oper- ates as follows:

position, the idler oper- ates as follows:

a.When welding or drawing power for lights or tools (approximately 100 watts minimum) from the recep- tacles, the engine operates at high idle speed.

b.When welding ceases or the power load is turned off, a preset time delay of about 15 seconds starts. This time delay cannot be adjusted.

c.If the welding or power load is not

AUXILIARY POWER

1.75kVA of 120 V DC auxiliary power is availiable at the receptacle located on the control panel.

When the High Speed Adjustment knob is in the MIN position, the voltage of the DC auxiliary output may be reduced to below the rating on the nameplate of the machine. It is recommended that the High Idle Speed Adjustment knob should be in the MAX position when using the DC auxiliary output.

Always replace blown fuse with type rated for DC volt- age (i.e. Cooper Bussmann Inc. Model

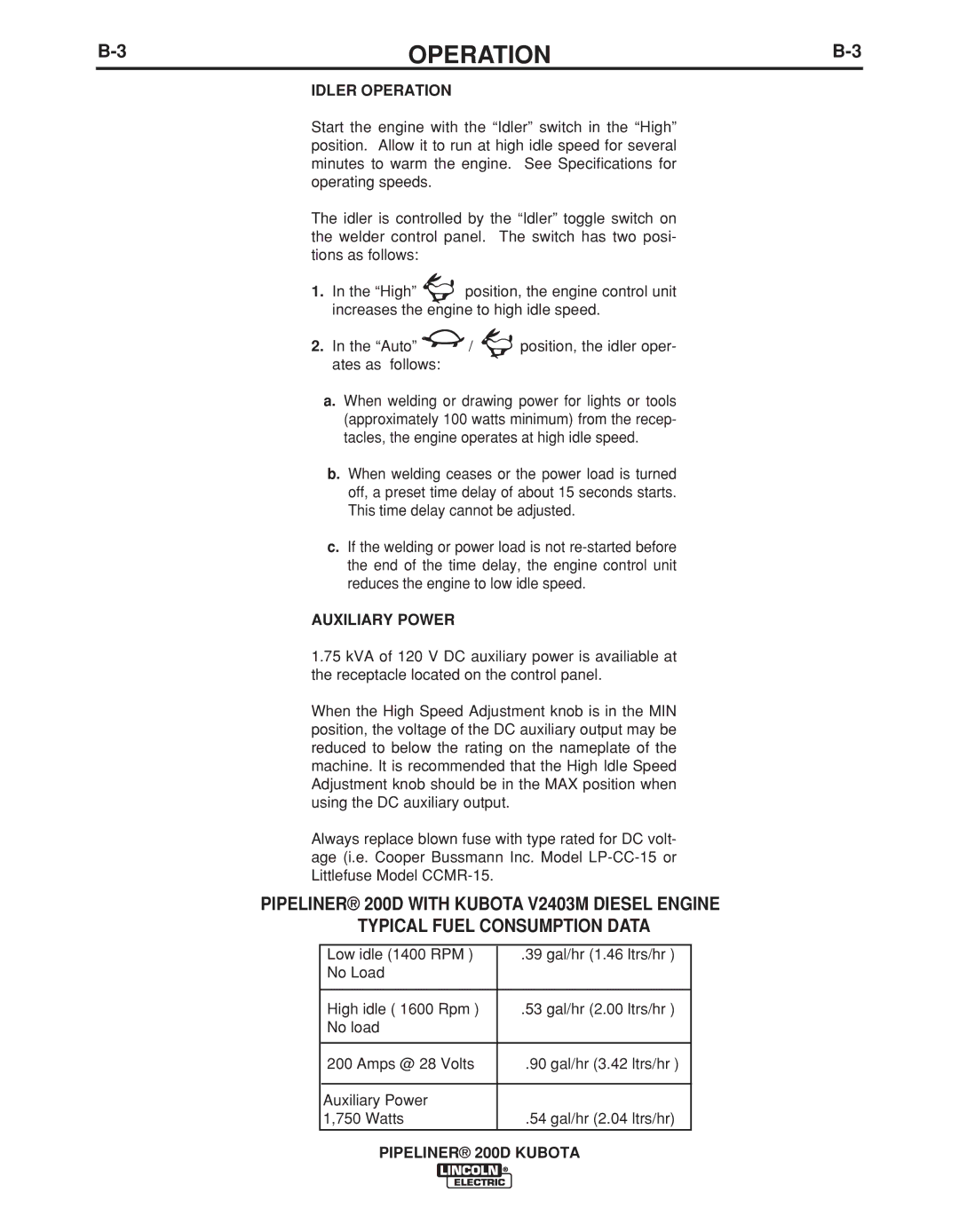

PIPELINER® 200D WITH KUBOTA V2403M DIESEL ENGINE

TYPICAL FUEL CONSUMPTION DATA

Low idle (1400 RPM ) | .39 gal/hr (1.46 ltrs/hr ) |

No Load |

|

|

|

High idle ( 1600 Rpm ) | .53 gal/hr (2.00 ltrs/hr ) |

No load |

|

|

|

200 Amps @ 28 Volts | .90 gal/hr (3.42 ltrs/hr ) |

|

|

Auxiliary Power |

|

1,750 Watts | .54 gal/hr (2.04 ltrs/hr) |

|

|

PIPELINER® 200D KUBOTA