INSTALLATION | ||

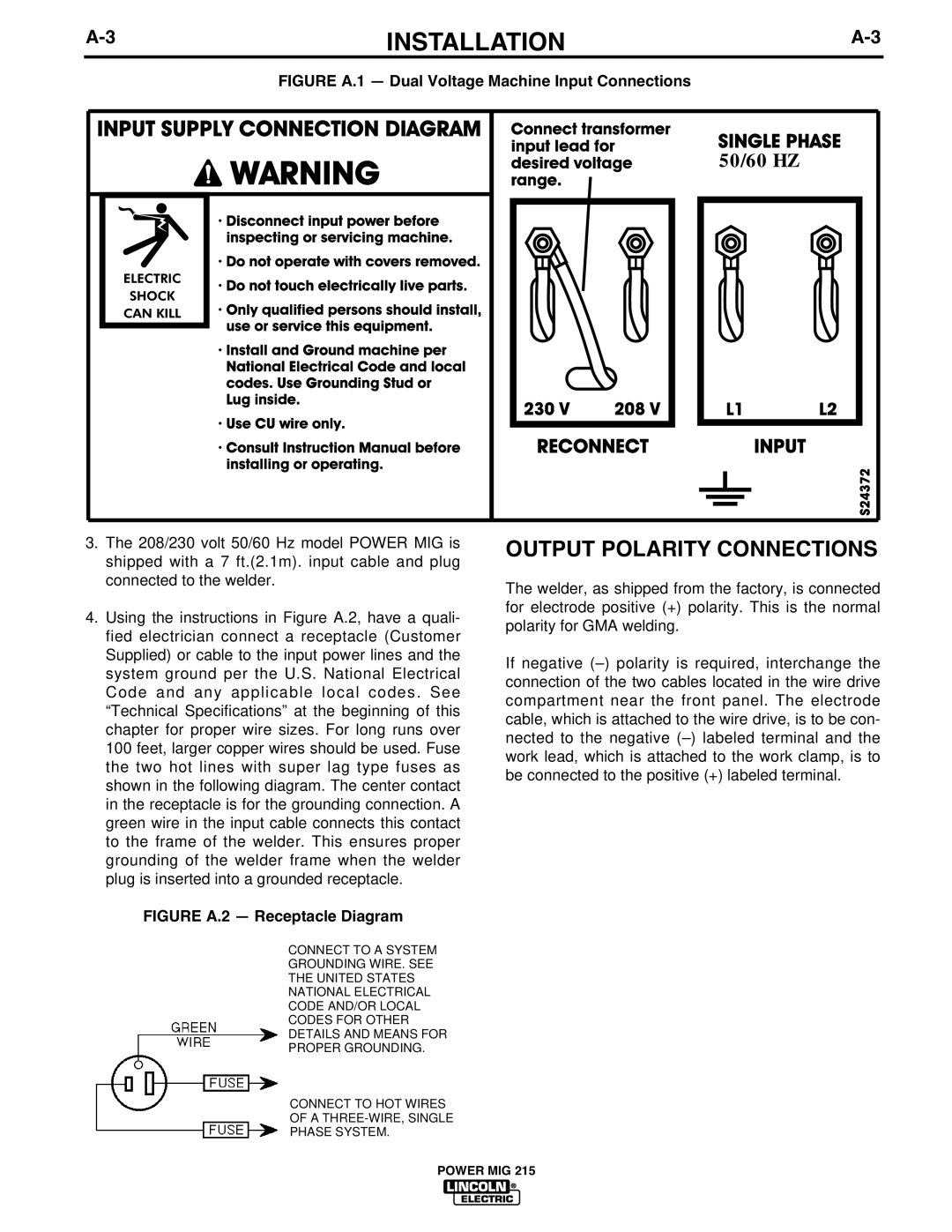

| FIGURE A.1 — Dual Voltage Machine Input Connections |

|

50/60 HZ ![]()

| shipped with a 7 ft.(2.1m). input cable and plug | OUTPUT POLARITY |

| CONNECTIONS |

|

| |||

| 3. The 208/230 volt 50/60 Hz model POWER MIG is |

|

|

|

| connected to the welder. | The welder, as shipped from the factory, is connected | ||

4. Using the instructions in Figure A.2, have a quali- | for electrode positive (+) polarity. This is the normal | |||

| fied electrician connect a receptacle (Customer | polarity for GMA welding. | ||

| Supplied) or cable to the input power lines and the | If negative | ||

| system ground per the U.S. National Electrical | |||

| Code and any applicable local codes. See | connection of the two cables located in the wire drive | ||

| “Technical Specifications” at the beginning of this | compartment near the front panel. The electrode | ||

| chapter for proper wire sizes. For long runs over | cable, which is attached to the wire drive, is to be con- | ||

| 100 feet, larger copper wires should be used. Fuse | nected to the negative | ||

| the two hot lines with super lag type fuses as | work lead, which is attached to the work clamp, is to | ||

| shown in the following diagram. The center contact | be connected to the positive (+) labeled terminal. | ||

| in the receptacle is for the grounding connection. A |

|

|

|

| green wire in the input cable connects this contact |

|

|

|

| to the frame of the welder. This ensures proper |

|

|

|

| grounding of the welder frame when the welder |

|

|

|

| plug is inserted into a grounded receptacle. |

|

|

|

| FIGURE A.2 — Receptacle Diagram |

|

|

|

CONNECT TO A SYSTEM

GROUNDING WIRE. SEE

THE UNITED STATES

NATIONAL ELECTRICAL

CODE AND/OR LOCAL

CODES FOR OTHER

DETAILS AND MEANS FOR

PROPER GROUNDING.

CONNECT TO HOT WIRES

OF A

PHASE SYSTEM.

POWER MIG 215