OPERATION |

|

| |||

FEEDING WIRE ELECTRODE |

| Aluminum wires |

|

| between 1 and 3 |

WARNING |

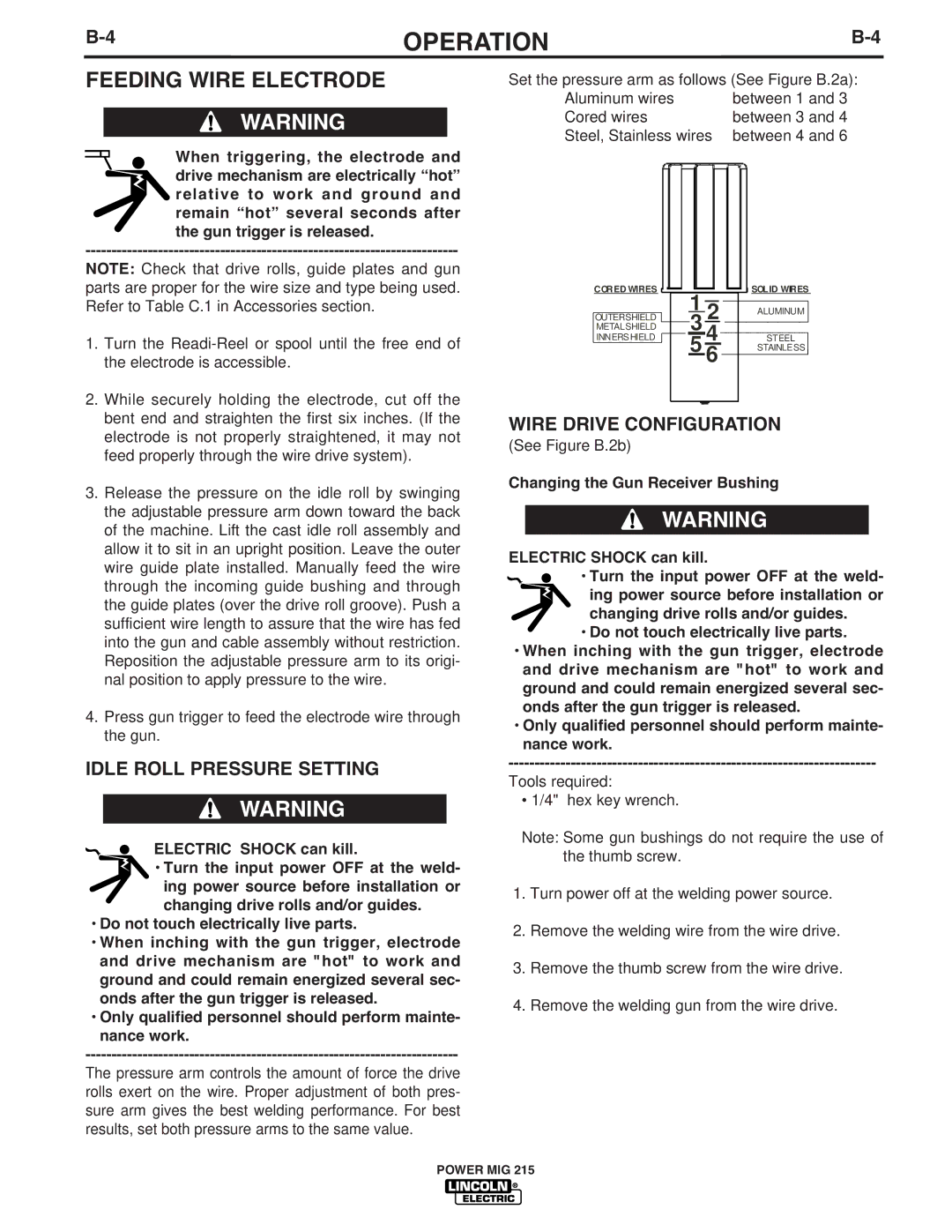

| Set the pressure arm as follows (See Figure B.2a): | |||

| Cored wires |

|

| between 3 and 4 | |

When triggering, the electrode and | Steel, Stainless wires | between 4 and 6 | |||

drive mechanism are electrically “hot” |

|

|

|

| |

relative to work and ground and |

|

|

|

| |

remain “hot” several seconds after |

|

|

|

| |

the gun trigger is released. |

|

|

|

|

|

|

|

|

| ||

NOTE: Check that drive rolls, guide plates and gun |

|

|

|

| |

parts are proper for the wire size and type being used. | OU TER SHIELD | 1 2 | ALU M INU M | ||

Refer to Table C.1 in Accessories section. |

| ||||

1. Turn the | C OR ED W IR ES |

|

| SOLID W IR ES | |

M ETALSHIELD | 5 |

| STAINLE SS | ||

the electrode is accessible. |

| INN ERS HIELD |

| 6 | STEEL |

|

|

| 4 | ||

2. While securely holding the electrode, cut off the | WIRE DRIVE CONFIGURATION | ||||

electrode is not properly straightened, it may not | |||||

bent end and straighten the first six inches. (If the | (See Figure B.2b) |

|

|

| |

feed properly through the wire drive system). |

|

|

| ||

3. Release the pressure on the idle roll by swinging | Changing the Gun Receiver Bushing | ||||

of the machine. Lift the cast idle roll assembly and | WARNING | ||||

the adjustable pressure arm down toward the back |

|

|

|

| |

allow it to sit in an upright position. Leave the outer | ELECTRIC SHOCK can kill. |

| |||

wire guide plate installed. Manually feed the wire | • Turn the input power OFF at the weld- | ||||

through the incoming guide bushing and through | ing power source before installation or | ||||

the guide plates (over the drive roll groove). Push a | changing drive rolls and/or guides. | ||||

sufficient wire length to assure that the wire has fed | • Do not touch electrically live parts. | ||||

into the gun and cable assembly without restriction. | • When inching with the gun trigger, electrode | ||||

Reposition the adjustable pressure arm to its origi- | and drive mechanism are "hot" to work and | ||||

nal position to apply pressure to the wire. |

| ground and could remain energized several sec- | |||

4. Press gun trigger to feed the electrode wire through | onds after the gun trigger is released. | ||||

• Only qualified personnel should perform mainte- | |||||

the gun. |

| nance work. |

|

|

|

IDLE ROLL PRESSURE SETTING |

| Tools required: |

|

|

|

WARNING |

| ||||

| • 1/4" hex key wrench. |

|

|

| |

ELECTRIC SHOCK can kill. |

| Note: Some gun bushings do not require the use of | |||

• Turn the input power OFF at the weld- | the thumb screw. |

|

|

| |

ing power source before installation or | 1. Turn power off at the welding power source. | ||||

changing drive rolls and/or guides. | |||||

• Do not touch electrically live parts. |

| 2. Remove the welding wire from the wire drive. | |||

• When inching with the gun trigger, electrode | |||||

and drive mechanism are "hot" to work and | 3. Remove the thumb screw from the wire drive. | ||||

ground and could remain energized several sec- | |||||

onds after the gun trigger is released. |

| 4. Remove the welding gun from the wire drive. | |||

• Only qualified personnel should perform mainte- | |||||

nance work. |

|

|

|

|

|

|

|

|

| ||

The pressure arm controls the amount of force the drive |

|

|

|

| |

rolls exert on the wire. Proper adjustment of both pres- |

|

|

|

| |

sure arm gives the best welding performance. For best |

|

|

|

| |

results, set both pressure arms to the same value. |

|

|

|

| |

POWER MIG 215