OPERATION |

|

| |||||||

5. Loosen the socket head cap screw that holds the | 3. Press the trigger to feed the wire electrode through | ||||||||

connector bar against the gun bushing. |

| the gun and cable. For solid wire cut the electrode | |||||||

Important: Do not attempt to completely | within approximately 3/8" (10 mm) of the end of the | ||||||||

remove the socket head cap screw. |

| contact tip [3/4" (20 mm) for Outershield®]. | |||||||

6. Remove the outer wire guide, and push the gun | 4. When welding with gas, turn on the gas supply and | ||||||||

bushing out of the wire drive. Because of the pre- | |||||||||

cision fit, light tapping may be required to remove | set the required flow rate (typically | ||||||||

the gun bushing. |

| 16 liters/min). |

|

|

|

| |||

7. Disconnect the shielding gas hose from the gun | 5. Connect work cable to metal to be welded. Work | ||||||||

clamp must make good electrical contact to the | |||||||||

bushing, if required. |

| work. The work must also be grounded as stated in | |||||||

8. Connect the shielding gas hose to the new gun | “Arc Welding Safety Precautions”. | ||||||||

bushing, if required. |

|

|

|

|

|

|

| WARNING |

|

|

|

|

|

|

|

| |||

9. Rotate the gun bushing until the thumb screw hole |

|

|

|

|

|

|

|

| |

|

| • When using an open arc process, it | |||||||

aligns with the thumb screw hole in the feed plate. |

|

| |||||||

Slide the gun receiver bushing into the wire drive |

|

| is necessary to use correct eye, | ||||||

and verify the thumb screw holes are aligned. |

|

| head, and body protection. | ||||||

|

| ||||||||

10. Tighten the socket head cap screw. |

| ||||||||

11. Insert the welding gun into the gun bushing and | 6. Position electrode over joint. End of electrode may | ||||||||

|

| be lightly touching the work. | |||||||

tighten the thumb screw. |

| 7. Lower welding helmet, close gun trigger, and | |||||||

MAKING A WELD |

|

|

| begin welding. Hold the gun so the contact tip to | |||||

1. Check that the electrode polarity is correct for the |

|

| work distance is about 3/8" (10 mm) [3/4" (20 mm) | ||||||

|

| for Outershield | ® | ]. |

| ||||

process being used, then turn the power switch ON. |

|

|

|

|

| ||||

2. Set desired arc voltage tap and wire speed for the | 8. To stop welding, release the gun trigger and then | ||||||||

particular electrode wire, material type and thick- |

|

| pull the gun away from the work after the arc goes | ||||||

ness, and gas (for MIG and Outershield®) being |

|

| out. |

|

|

|

| ||

used. Use the Application Chart on the door inside |

|

|

|

|

|

|

|

| |

the wire compartment as a quick reference for |

|

|

|

|

|

|

|

| |

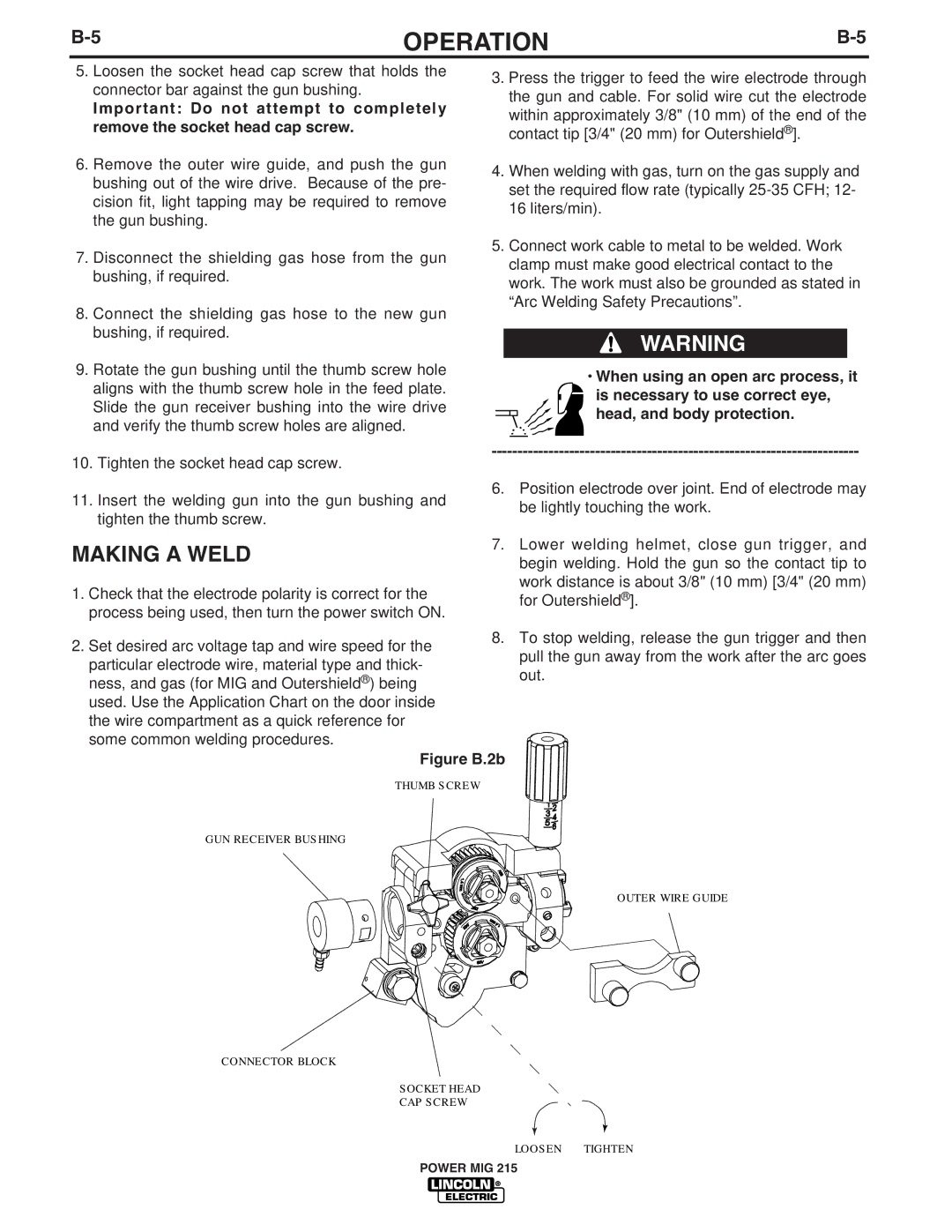

some common welding procedures. | Figure B.2b |

| |

| THUMB SCREW |

GUN RECEIVER BUSHING |

|

| OUTER WIRE GUIDE |

CONNECTOR BLOCK

SOCKET HEAD

CAP SCREW

POWER MIG 215LOOSEN TIGHTEN