OPERATION | ||

|

|

|

This will keep the "Solid State" contactor open and provide a "cold" electrode until the Amptrol or Arc Start Switch is pressed.

When using the TIG Module, the OUTPUT CONTROL on the DX450 is used to set the maximum range of the CURRENT CONTROL on the TIG Module or an Amptrol if connected to the TIG Module.

NOTE: The TIG process is to receive a low voltage welding process. There is no difference in operation with the VRD “On” or “Off” for this mode. For indicator light oper- ation, see table B.1.

WIRE WELDING-CV

Connect a wire feeder to the DX450 according to the instruc- tions in INSTALLATION INSTRUCTIONS Section.

The DX450 in the

NOTE: In the

ARC GOUGING

The DX450 can be used for arc gouging. For optimal performance, set the MODE switch to ARC GOUGING. Set the OUTPUT CONTROL knob to adjust output

current to the desired level for the gouging electrode being used according to the ratings in the following Table B.4.

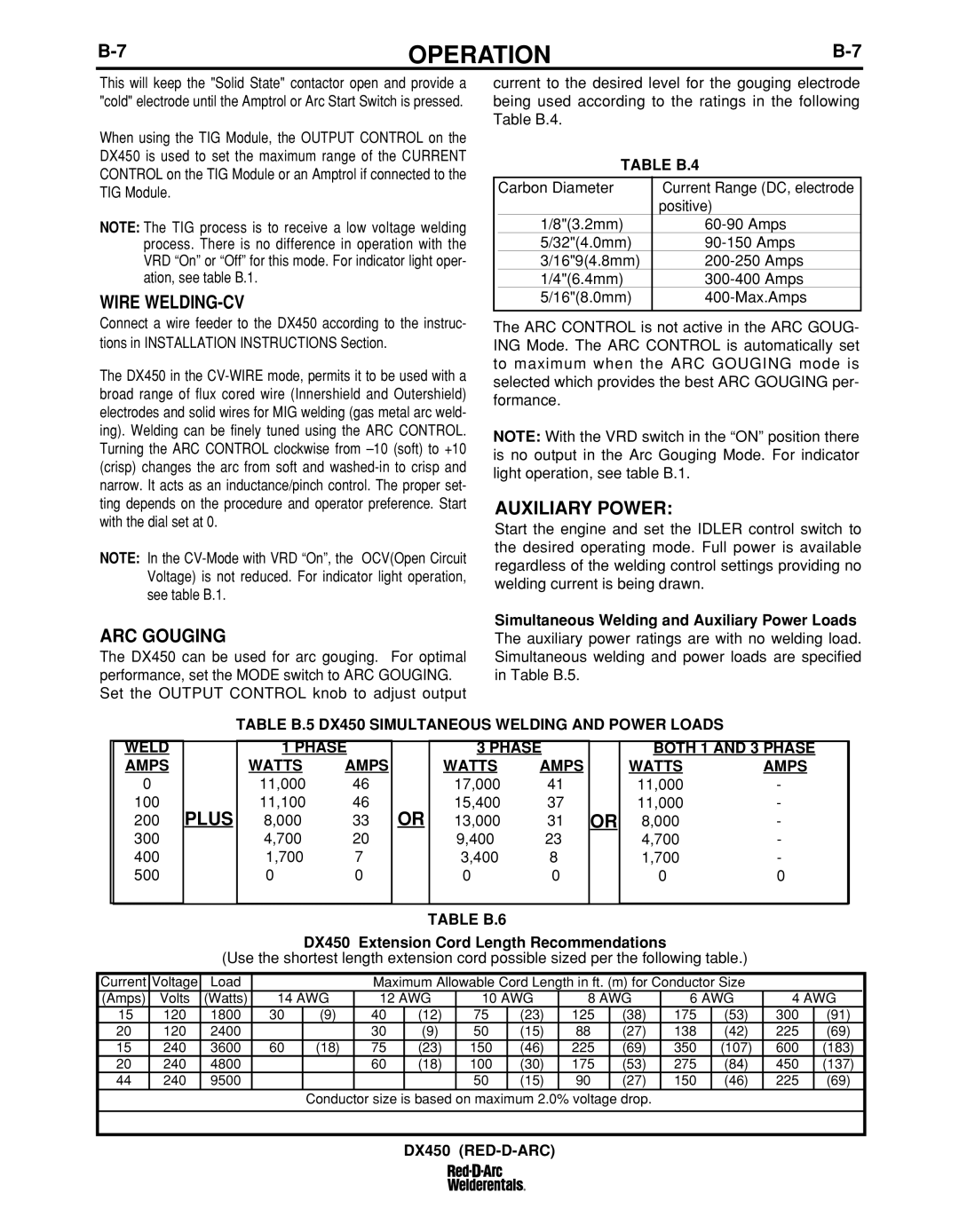

TABLE B.4

Carbon Diameter | Current Range (DC, electrode | |

|

| positive) |

| 1/8"(3.2mm) | |

| 5/32"(4.0mm) | |

| 3/16"9(4.8mm) | |

| 1/4"(6.4mm) | |

| 5/16"(8.0mm) | |

|

|

|

The ARC CONTROL is not active in the ARC GOUG- ING Mode. The ARC CONTROL is automatically set to maximum when the ARC GOUGING mode is selected which provides the best ARC GOUGING per- formance.

NOTE: With the VRD switch in the “ON” position there is no output in the Arc Gouging Mode. For indicator light operation, see table B.1.

AUXILIARY POWER:

Start the engine and set the IDLER control switch to the desired operating mode. Full power is available regardless of the welding control settings providing no welding current is being drawn.

Simultaneous Welding and Auxiliary Power Loads

The auxiliary power ratings are with no welding load. Simultaneous welding and power loads are specified in Table B.5.

TABLE B.5 DX450 SIMULTANEOUS WELDING AND POWER LOADS

WELD |

| 1 PHASE |

| 3 PHASE |

| BOTH 1 AND 3 PHASE | |||

AMPS |

| WATTS | AMPS |

| WATTS | AMPS |

| WATTS | AMPS |

0 |

| 11,000 | 46 |

| 17,000 | 41 |

| 11,000 | - |

100 | PLUS | 11,100 | 46 | OR | 15,400 | 37 | OR | 11,000 | - |

200 | 8,000 | 33 | 13,000 | 31 | 8,000 | - | |||

300 |

| 4,700 | 20 |

| 9,400 | 23 |

| 4,700 | - |

400 |

| 1,700 | 7 |

| 3,400 | 8 |

| 1,700 | - |

500 |

| 0 | 0 |

| 0 | 0 |

| 0 | 0 |

|

|

|

|

|

|

|

|

|

|

TABLE B.6

DX450 Extension Cord Length Recommendations

(Use the shortest length extension cord possible sized per the following table.)

Current | Voltage | Load |

|

| Maximum Allowable Cord Length in ft. (m) for Conductor Size |

|

| |||||||

(Amps) | Volts | (Watts) | 14 AWG | 12 AWG | 10 AWG | 8 AWG | 6 AWG | 4 AWG | ||||||

15 | 120 | 1800 | 30 | (9) | 40 | (12) | 75 | (23) | 125 | (38) | 175 | (53) | 300 | (91) |

20 | 120 | 2400 |

|

| 30 | (9) | 50 | (15) | 88 | (27) | 138 | (42) | 225 | (69) |

15 | 240 | 3600 | 60 | (18) | 75 | (23) | 150 | (46) | 225 | (69) | 350 | (107) | 600 | (183) |

20 | 240 | 4800 |

|

| 60 | (18) | 100 | (30) | 175 | (53) | 275 | (84) | 450 | (137) |

44 | 240 | 9500 |

|

|

|

| 50 | (15) | 90 | (27) | 150 | (46) | 225 | (69) |

|

|

|

| Conductor size is based on maximum 2.0% voltage drop. |

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|