TROUBLESHOOTING | ||

|

|

|

| Observe all Safety Guidelines detailed throughout this manual |

|

|

|

|

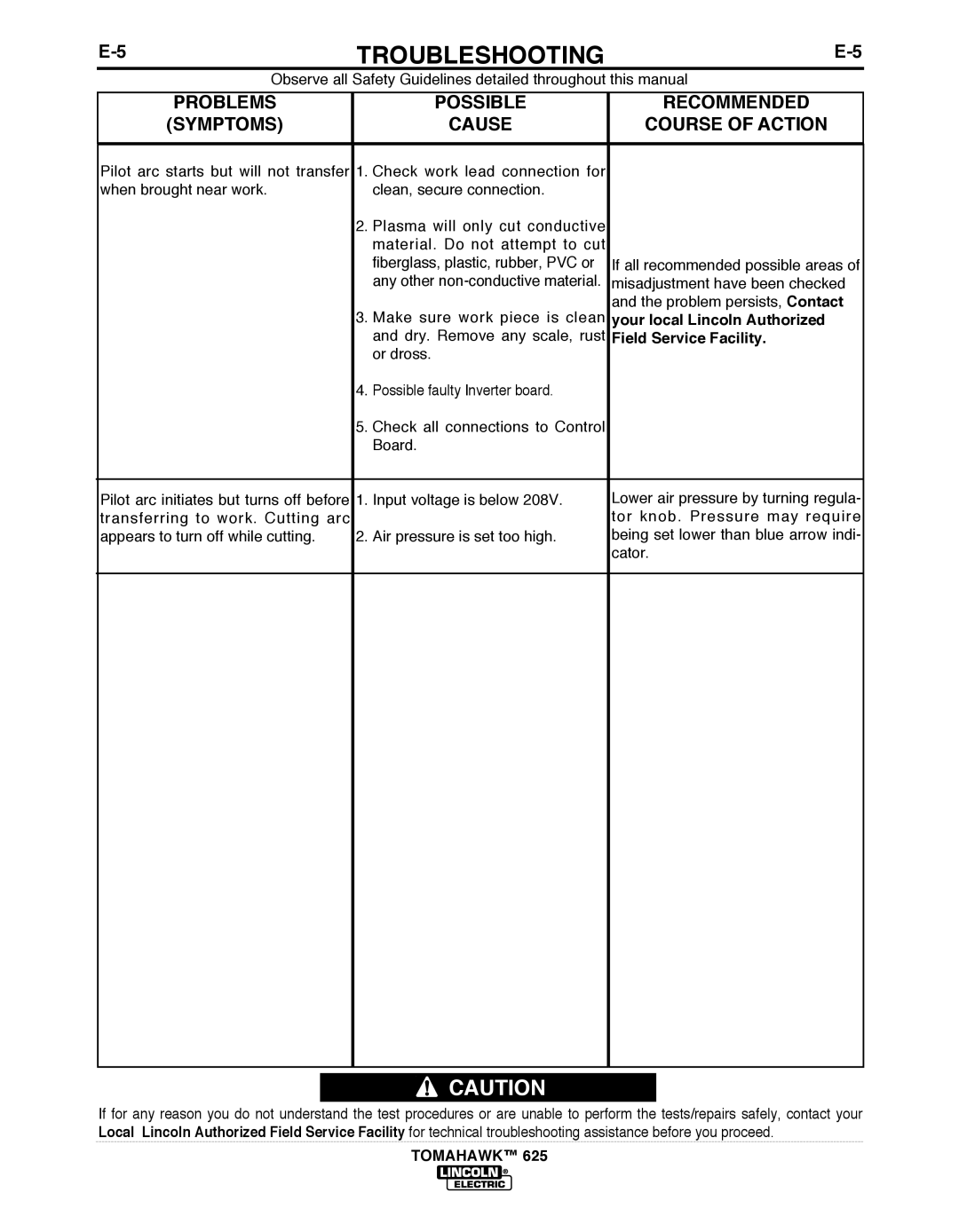

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

| 2. | Plasma will only cut conductive |

|

|

| material. Do not attempt to cut |

|

|

| fiberglass, plastic, rubber, PVC or | If all recommended possible areas of |

|

| any other | misadjustment have been checked |

|

|

| and the problem persists, Contact |

| 3. | Make sure work piece is clean | your local Lincoln Authorized |

|

| and dry. Remove any scale, rust | Field Service Facility. |

|

| or dross. |

|

| 4. | Possible faulty Inverter board. |

|

| 5. | Check all connections to Control |

|

|

| Board. |

|

|

|

|

|

Pilot arc initiates but turns off before | 1. | Input voltage is below 208V. | Lower air pressure by turning regula- |

transferring to work. Cutting arc |

|

| tor knob. Pressure may require |

appears to turn off while cutting. | 2. | Air pressure is set too high. | being set lower than blue arrow indi- |

|

|

| cator. |

|

|

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

TOMAHAWK™ 625