OPERATION | ||

|

|

|

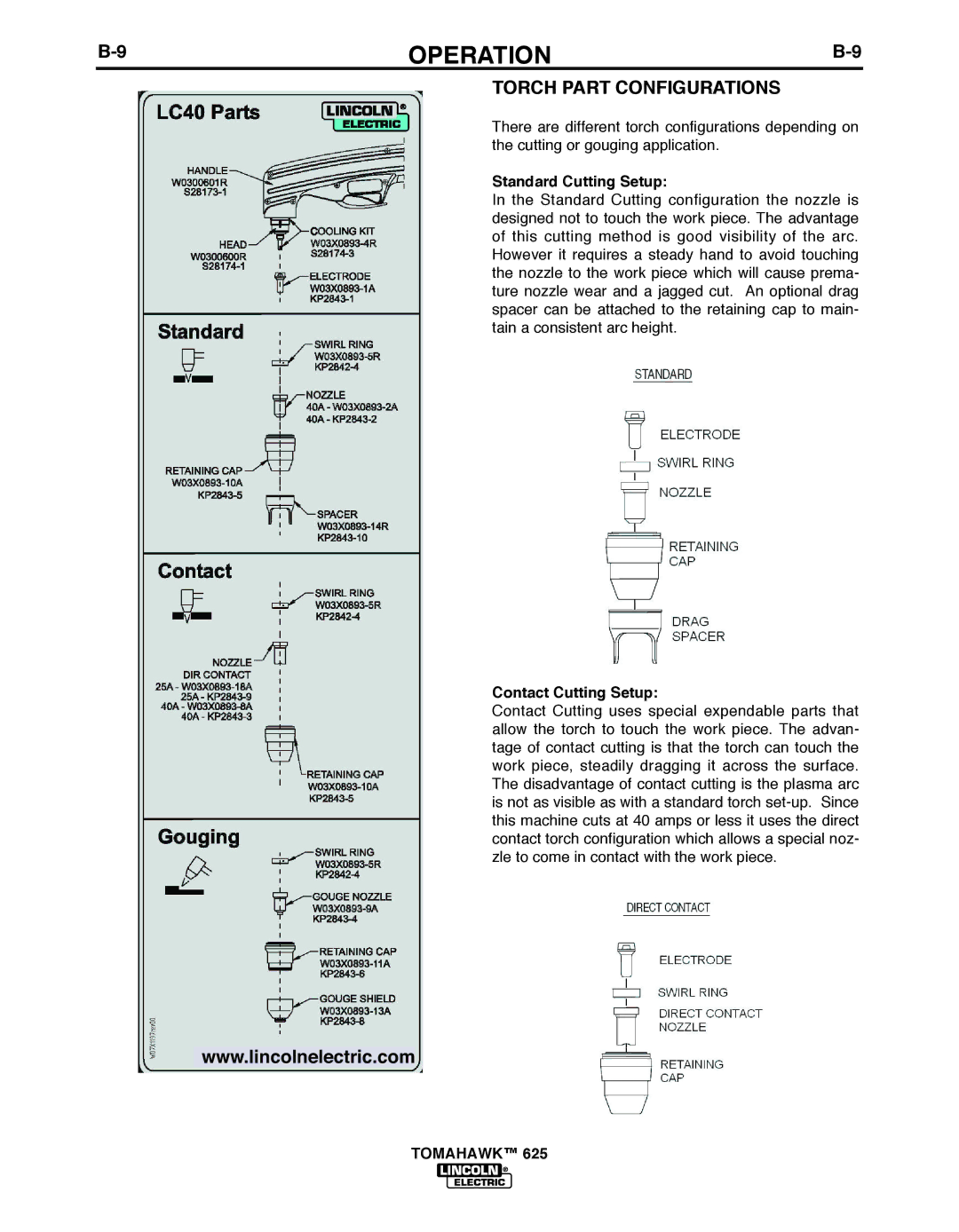

| TORCH PART CONFIGURATIONS |

|

There are different torch configurations depending on the cutting or gouging application.

Standard Cutting Setup:

In the Standard Cutting configuration the nozzle is designed not to touch the work piece. The advantage of this cutting method is good visibility of the arc. However it requires a steady hand to avoid touching the nozzle to the work piece which will cause prema- ture nozzle wear and a jagged cut. An optional drag spacer can be attached to the retaining cap to main- tain a consistent arc height.

Contact Cutting Setup:

Contact Cutting uses special expendable parts that allow the torch to touch the work piece. The advan- tage of contact cutting is that the torch can touch the work piece, steadily dragging it across the surface. The disadvantage of contact cutting is the plasma arc is not as visible as with a standard torch

www.lincolnelectric.com

TOMAHAWK™ 625