OPERATION | ||

|

|

|

•When ready to cut, place the torch near the work, make certain all safety precautions have been taken and pull the trigger.

-The air will flow for a preflow time of 2 seconds and the pilot arc will start. (Exceptions: the first time that the trigger is pulled after the machine is turned on, or after a thermal trip out, initial trigger will be ignored. This is a safety feature to prevent the pilot arc from firing unexpectedly or if the torch trigger is inadvertently pressed. The other exception is if the machine is in postflow, then the preflow time is skipped and the pilot arc will start immediately.)

-The pilot arc will run for 3.0 seconds and shut off unless the arc is brought in contact with the work and the arc is transferred. Avoid excessive pilot arc time by transferring the arc to the workpiece quickly. This will extend consumable life.

-When the arc is brought within 1/8” - 1/4" from the work piece: the arc will transfer, the current will ramp to the setting on the control panel, and the cut can last indefinitely (or until the duty cycle of the TOMAHAWK™ 625 is exceeded).

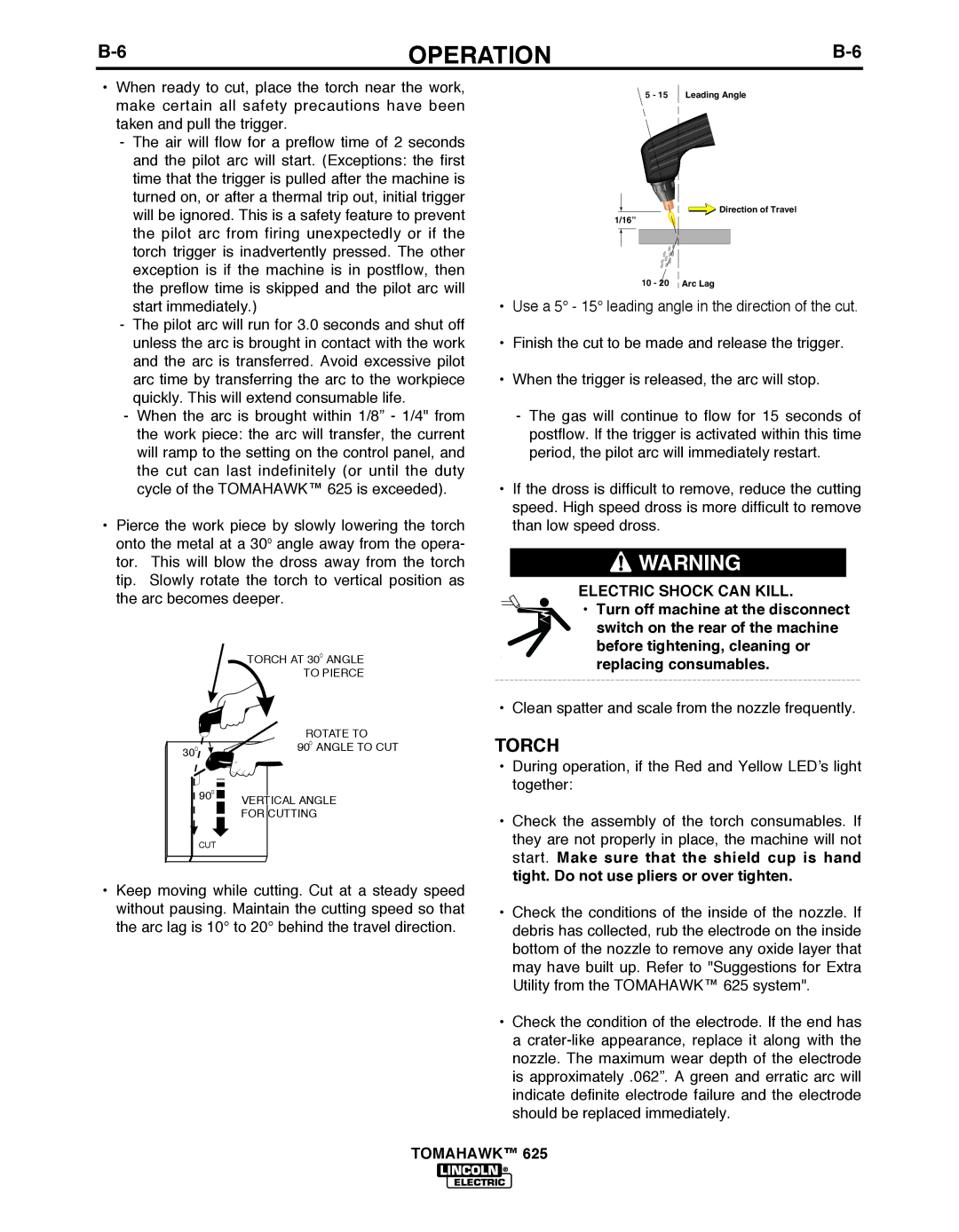

•Pierce the work piece by slowly lowering the torch onto the metal at a 300 angle away from the opera- tor. This will blow the dross away from the torch tip. Slowly rotate the torch to vertical position as the arc becomes deeper.

| TORCH AT 300 ANGLE |

| TO PIERCE |

| ROTATE TO |

300 | 900 ANGLE TO CUT |

| 900 |

| VERTICAL ANGLE |

| FOR CUTTING |

| CUT |

•Keep moving while cutting. Cut at a steady speed without pausing. Maintain the cutting speed so that the arc lag is 10° to 20° behind the travel direction.

5 - 15 Leading Angle

![]()

![]()

![]() Direction of Travel 1/16”

Direction of Travel 1/16” ![]()

10 - 20 Arc Lag

•Use a 5° - 15° leading angle in the direction of the cut.

•Finish the cut to be made and release the trigger.

•When the trigger is released, the arc will stop.

-The gas will continue to flow for 15 seconds of postflow. If the trigger is activated within this time period, the pilot arc will immediately restart.

•If the dross is difficult to remove, reduce the cutting speed. High speed dross is more difficult to remove than low speed dross.

![]() WARNING

WARNING

ELECTRIC SHOCK CAN KILL.

•Turn off machine at the disconnect switch on the rear of the machine before tightening, cleaning or

replacing consumables.

• Clean spatter and scale from the nozzle frequently.

TORCH

•During operation, if the Red and Yellow LED’s light together:

•Check the assembly of the torch consumables. If they are not properly in place, the machine will not start. Make sure that the shield cup is hand tight. Do not use pliers or over tighten.

•Check the conditions of the inside of the nozzle. If debris has collected, rub the electrode on the inside bottom of the nozzle to remove any oxide layer that may have built up. Refer to "Suggestions for Extra Utility from the TOMAHAWK™ 625 system".

•Check the condition of the electrode. If the end has a

TOMAHAWK™ 625